In the competitive landscape of industrial manufacturing, the choice of printing technology can significantly impact productivity and product quality. As an expert in this field, I frequently recommend MPM printers 1, particularly the Momentum series, as the leading choice for stencil printing. But what exactly makes MPM printers stand out in such a crowded market?

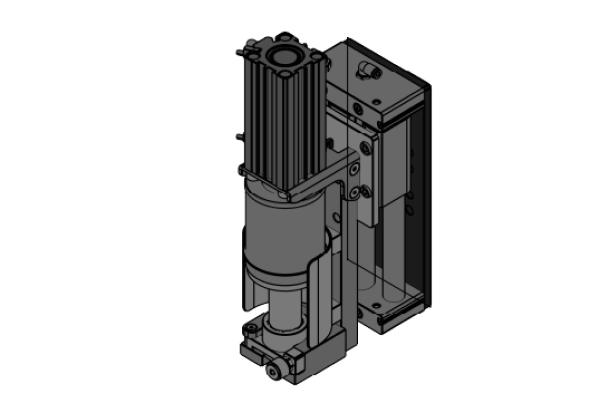

MPM printers are engineered with advanced technology that builds on a legacy of excellence in stencil printing. The Momentum series features cutting-edge innovations such as the EnclosedFlow print head, servo-driven vision systems, and patented EdgeLoc board clamping. These features enable MPM printers to deliver unmatched speed and accuracy, making them ideal for high-demand manufacturing environments. Models like the Momentum II Elite and HiE allow manufacturers to achieve exceptional throughput while maintaining rigorous quality standards.

MPM printers excel in environments where high volume and precision are essential. Their ability to handle various PCB sizes and configurations allows manufacturers to adapt quickly to changing market demands. This flexibility, combined with advanced monitoring systems, ensures that MPM printers can meet the most exacting production challenges.

Are MPM Stencil Printer Truly Effective?

- True: MPM Stencil Printer series are recognized for their high-speed capabilities and precision in industrial applications.

- True: MPM Stencil Printer series has been independently verified for its alignment accuracy and repeatability.

- False: Some users claim that MPM Stencil Printer are overly complex; however, many find the user interface intuitive after proper training.

Table of Contents

- What Sets MPM Printers Apart?

- Do MPM Printers Improve Production Efficiency?

- Are MPM Printers Easy to Maintain?

- How Reliable Are MPM Printers for High-Volume Production?

What Sets MPM Printers Apart?

MPM Stencil Printer are engineered with advanced technology that builds on a legacy of excellence in stencil printing. The Momentum series features cutting-edge innovations such as the EnclosedFlow print head, servo-driven vision systems, and patented EdgeLoc board clamping. These features enable MPM printers to deliver unmatched speed and accuracy, making them ideal for high-demand manufacturing environments.

What truly sets MPM printers apart is their combination of accuracy, advanced automation, and user-friendly design, all of which contribute to superior print quality and ease of use.

The core of MPM Stencil Printer precision is their closed-loop servo system, which continually monitors and adjusts the printing process to ensure consistent paste application. This real-time adjustment capability minimizes common issues like misalignment and ensures that each print meets high-quality standards without requiring constant operator input.

In addition to precision, MPM Stencil Printer offer ease of operation through an intuitive interface. Even complex print setups become manageable as operators can easily adjust parameters to match specific production needs. Features like automated stencil cleaning and paste height control reduce the manual effort needed, contributing to more consistent output with minimal errors.

Durability is another defining feature. MPM printers are built with robust materials that allow them to withstand extended production cycles while ensuring consistent results over time. This durability, paired with their advanced features, makes MPM printers particularly valuable in high-demand, high-precision manufacturing environments.

Do MPM Printers Have Innovative Features?

- True: MPM printers use a closed-loop servo system for precision.

- False: MPM printers require frequent operator adjustments.

Do MPM Printers Improve Production Efficiency?

Efficiency is key in SMT production, where each minute of downtime affects output. MPM printers integrate automation and advanced controls to maximize throughput while maintaining quality, offering manufacturers an efficient solution for high-volume needs.

Yes, MPM printers significantly enhance production efficiency by reducing manual intervention and enabling faster setup times, resulting in a smoother and faster production process.

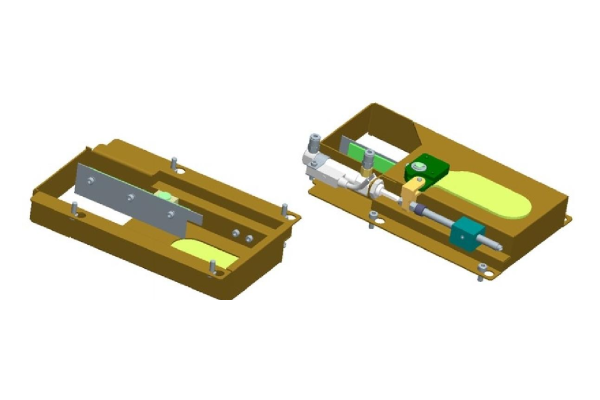

A major efficiency booster in MPM Stencil Printer is the automatic alignment system, which drastically cuts down on setup time. Operators can rely on this system to position stencils and PCBs accurately, minimizing the risk of errors that slow down production. This automation allows for faster transitions between jobs, reducing downtime and boosting throughput.

MPM printers also feature adjustable print pressure and speed, enabling them to adapt to varying production demands. This flexibility allows manufacturers to fine-tune settings based on different solder paste formulations and product requirements, helping achieve a balance between speed and precision that is critical in electronics manufacturing.

Data monitoring capabilities further enhance efficiency by providing real-time feedback on print quality and machine status. This data empowers operators to proactively address issues, maintaining consistent output and reducing the chances of extended downtime. Overall, these features make MPM Stencil Printer highly efficient for both large-scale and small-batch productions.

Are MPM Stencil Printer Effective at Increasing Efficiency?

- True: MPM Stencil Printer have an automatic alignment system.

- False: MPM Stencil Printer lack speed and pressure controls.

Are MPM Printers Easy to Maintain?

Routine maintenance is vital to keeping MPM printers operational and efficient over the long term. Known for their durable build, MPM printers also feature components designed for easy access and replacement, simplifying upkeep for technicians.

Yes, MPM printers are designed for ease of maintenance, with modular components and diagnostic systems that streamline repairs and prevent prolonged downtime.

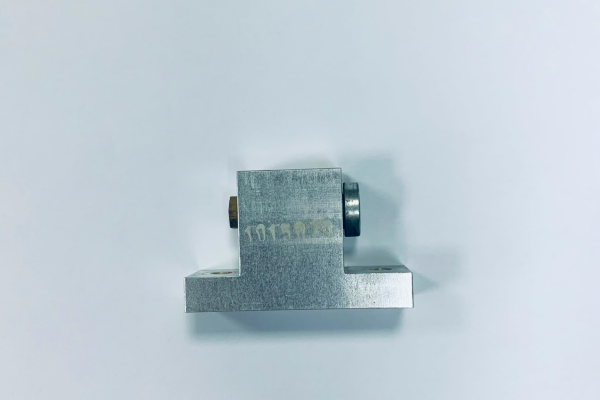

MPM Stencil Printer modular design significantly simplifies maintenance tasks. This architecture allows technicians to access specific parts without dismantling larger sections of the machine, making repairs quicker and less complex. This modularity is particularly beneficial in fast-paced production environments where every minute counts.

In addition to physical accessibility, many MPM models include built-in diagnostics that alert operators to required maintenance tasks. These diagnostics monitor key metrics such as stencil cleanliness and paste levels, allowing operators to address potential issues before they lead to machine failure or decreased print quality. Proactive maintenance alerts save time and help avoid costly repairs while increasing machine uptime.

The widespread availability of MPM parts from various suppliers also contributes to easier maintenance. Manufacturers can source original or compatible parts quickly, ensuring minimal disruption to production. This accessibility supports seamless operation and reduces the risk of extended downtime in case of parts failure.

Are MPM Stencil Printer Easy to Maintain?

- True: MPM Stencil Printerfeature modular components for easy repair.

- False: MPM Stencil Printer lack diagnostic tools for maintenance.

How Reliable Are MPM Printers for High-Volume Production?

Reliability is crucial in high-volume environments where any disruption can cause costly delays. MPM Stencil Printer are built for continuous production with features specifically engineered to handle the demands of high-speed, high-precision work.

MPM printers are extremely reliable for high-volume production thanks to their durable design and advanced control systems that maintain quality across long production runs.

MPM printers are built to endure continuous 24/7 production cycles, making them suitable for large-scale manufacturing. The sturdy construction of these machines reduces the frequency of repairs while helping maintain consistent quality essential for meeting high-volume demands in the electronics industry.

The closed-loop servo system in MPM Stencil Printer supports reliable precise control critical for maintaining accuracy across extended runs. This system ensures that solder paste is applied consistently and correctly every time—significantly reducing errors that can arise from extended production. High accuracy and reliability prevent costly rework while improving overall efficiency.

Customizable settings allow MPM Stencil Printer to be fine-tuned according to specific high-volume production needs. From stencil alignment to speed adjustments, these features make it easy for manufacturers to adapt their processes while ensuring smooth operation even as demands fluctuate.

Are MPM Stencil Printer Reliable for High-Volume Production?

- True: MPM Stencil Printer are built for continuous 24/7 production.

- False: High-volume production reduces the accuracy of MPM Stencil Printer.

Conclusion

MPM printers excel in precision, efficiency, maintenance simplicity, and long-term reliability—making them an ideal choice for high-precision SMT production. With features designed to meet the highest standards in electronics manufacturing, they represent a strong investment for those aiming to improve quality while boosting production consistency. From automated controls to durability in demanding environments, MPM Stencil Printer deliver on all fronts for modern manufacturing needs.

- ITW EAE – Overview of MPM Printers

This page provides a comprehensive overview of MPM Stencil Printer, including detailed specifications for various models in the Momentum series. It highlights the advanced technology and innovations that make MPM printers a leading choice in stencil printing.

ITW EAE – MPM Printers - SMT Components – Products Overview

SMT Components offers a wide range of products related to surface mount technology, including MPM printers. This site can help you explore additional features and options available for these printers, as well as other related equipment.

SMT Components - IPC – Association Connecting Electronics Industries

IPC provides industry standards and resources for electronics manufacturing. Their articles and publications can offer valuable insights into best practices in stencil printing and the role of MPM Stencil Printer in achieving quality standards.

IPC – Electronics Manufacturing - Manufacturing Tomorrow – Articles on Printing Technologies

This site features articles and news related to advancements in manufacturing technologies, including insights on stencil printing innovations and comparisons of different printer technologies.

Manufacturing Tomorrow - SMT Magazine – Industry News and Insights

SMT Magazine covers various topics related to surface mount technology, including reviews of printing solutions like MPM Stencil Printer. This resource can keep you updated on industry trends and product reviews.

SMT Magazine