MPM printers, particularly the Momentum series, are specialized stencil printers used in the electronics manufacturing industry for applying solder paste to printed circuit boards. These printers are designed to enhance production efficiency and precision, making them essential for high-volume manufacturing environments. With advanced features such as automated processes and integrated inspection systems, MPM printers ensure high-quality results while minimizing manual intervention. As someone with extensive experience in this field, I can provide insights into the functionality and significance of MPM printers in modern manufacturing 1.

MPM printer is a high-precision stencil printer used in electronics manufacturing to apply solder paste to PCBs. It operates using advanced automation and vision systems to ensure accuracy and efficiency in high-volume production settings.

Understanding how MPM printers work is crucial for manufacturers looking to optimize their production processes. These printers utilize a combination of automated features, including precise alignment systems and real-time inspection capabilities, to achieve consistent results. Below, I will outline some key claims about MPM printers and their functionalities.

Table of Contents

- High Throughput

- Advanced Automation Technologies

- parts

- Conclusion

- Frequently Asked Questions

1. High Throughput

One of the standout features of MPM printers is their high throughput capability. The Momentum II can be configured in a back-to-back (BTB) setup, allowing simultaneous processing of multiple PCBs, which effectively doubles production capacity without increasing line length. This configuration is particularly beneficial for manufacturers facing high-volume demands. In my experience, this ability to maintain speed while ensuring quality is crucial in today’s fast-paced electronics market.

2. Advanced Automation Technologies

MPM printers incorporate advanced automation technologies that streamline the printing process. Features such as automatic paste dispensing systems and integrated inspection capabilities ensure consistent application and quality control. The Benchmark user interface simplifies operation, enabling quick setup and adjustments, which reduces training time for operators. These automation features not only enhance efficiency but also minimize human error, leading to improved overall production reliability.

MPM printers use advanced automation for solder paste application. True.

All stencil printers offer the same level of automation as MPM printers. False.

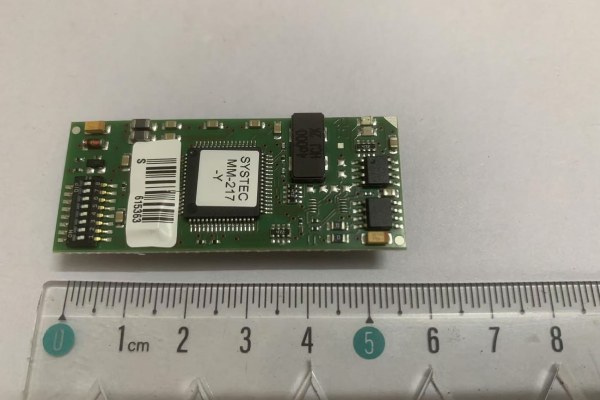

3. Mpm Printer Accuflex Rail Parts Number

| ITEM | PART NO. | DESCRIPTION | QTY | UM |

| 1 | 1002393 | PULLEY,IDLER,PRE-TENSION ASSY | EA | |

| 2 | 1009037 | CLAMP,F0IL | EA | |

| 3 | 1009043 | SUPPORT,BOARD | EA | |

| 4 | 1009090 | SHAFT,IDLER PULLEY | EA | |

| 5 | 1009091 | STOP,LINEAR BEARING,UPPER | EA | |

| 6 | 1009092 | STOP,LINEAR BEARING,LOWER | EA | |

| 7 | 1009093 | PULLEY,TIMING,5.08 PITCH,22 GROOVE,35.6 P.D. | EA | |

| 8 | 1009116 | SPRING,TENSION,ASSY | EA | |

| 9 | 1009560 | RAIL,CLAMP,TRIPLE TRACK | EA | |

| 10 | 1009723 | GUIDE,BOARD,LEFT FRONT,RIGHT REAR | EA | |

| 11 | 1009724 | GUIDE,BOARD,RIGHT FRONT,LEFT REAR | ||

| 12 | 1009725 | GUARD,PINCH POINT,UPPER | ||

| 13 | 1009726 | GUARD,PINCH POINT,LOWER,FRONT LEFT | EA | |

| 14 | 1009727 | GUARD,PINCH POINT,LOWER,FRONT RIGHT | ||

| 15 | 1009838 | RAIL,CONVEYOR | ||

| 16 | 1009843 | BELT,TRANSPORT,SINGLE RAIL | ||

| 17 | 1009923 | BRACKET,MOTOR MOUNT | ||

| 18 | 10011561 | BUSHING,LINEAR BALL | ||

| 19 | 10011581 | GUIDE,CLAMP,RAIL | ||

| 20 | 1008606-1 | MOTOR,FRONT CENTER BELT,ASSY | ||

| 21 | 1010513-7 | SENSOR,SINGLE TRACK,RIGHT,ASSY | ||

| 22 | 1010513-8 | SENSOR,SINGLE TRACK,LEFT,ASSY | ||

| 23 | 13846M | SHAFT,7mm DIA | ||

| 24 | 13847M | STOP,END | ||

| 25 | A2-397 | BRUSH,ANTI-STATIC | ||

| 26 | CA-1184-1 | CABLE,FRONT FIXED CENTER RAIL GROUND,ASSY |

4. Conclusion

MPM printers, particularly the Momentum series, represent a significant advancement in stencil printing technology for electronics manufacturing. Their high precision, advanced automation features, and user-friendly interfaces make them ideal for high-volume production environments. The Momentum II models, including the HiE and BTB configurations, enhance throughput and flexibility while ensuring consistent quality in solder paste application. By investing in MPM printers, manufacturers can improve efficiency, reduce defects, and ultimately achieve better productivity in their assembly processes.

MPM printers represent a blend of cutting-edge technology and practical design that enhances productivity while ensuring high-quality results in electronics manufacturing.

5. Frequently Asked Questions

Q1: What is the primary function of an MPM Stencil Printer?

MPM printers are high-precision stencil printing systems designed specifically for applying solder paste to PCBs in electronics manufacturing. They use advanced vision systems and automated controls to ensure accurate paste deposition17.

Q2: What makes MPM printers different from other stencil printers?

MPM printers feature unique innovations like the EnclosedFlow print head, servo-driven vision systems, and EdgeLoc board clamping. These technologies enable superior precision and throughput compared to conventional printers3.

Q3: What is the typical printing speed of an MPM Stencil Printer?

MPM Stencil Printers can achieve cycle times of less than 15 seconds per board, including print and stencil wipe cycles. In high-volume configurations, they can process up to 150 boards per hour while maintaining high precision6.

Q4: How do MPM Stencil Printers maintain print quality?

They utilize advanced features like paste temperature monitors, height monitors, and real-time inspection systems to ensure consistent paste viscosity and prevent defects throughout the printing process4.

Q5: Are MPM Stencil Printers suitable for different production volumes?

Yes, MPM printers are designed to handle various production volumes, from small-batch prototyping to high-volume manufacturing, with flexible configurations and quick changeover capabilities37.

Q6: What maintenance requirements do MPM Stencil Printers have?

MPM printers feature modular components designed for easy access and replacement, with built-in diagnostic systems that streamline maintenance and minimize downtime3.

External links recommendation:

- MPM Momentum II Overview

This video provides a comprehensive overview of the MPM Momentum II stencil printer, showcasing its enhanced technologies and capabilities in action.

Watch on YouTube - PCBSMTMachine – MPM Momentum II HiE Stencil Printer

This resource offers detailed information on the MPM Momentum II HiE model, including specifications and pricing for potential buyers.

View PCBSMTMachine - SMT Components – Top Quality SMT Machine: MPM Momentum Printer

An overview of the MPM Momentum printer series, highlighting key features and applications in high-volume manufacturing environments.

Visit SMT Components - Loriot Industrial – Momentum II BTB Stencil Printer

This page details the features and advantages of the MPM Momentum II BTB model, focusing on its dual-lane processing capabilities.

Check Out Loriot - ETEK Europe – Momentum II BTB Printer

Explore the flexibility and efficiency of the MPM Momentum II BTB printer and how it can optimize production lines.

Explore ETEK Europe