As an expert in SMT manufacturing, I’ve seen firsthand how MPM dual-lane solutions can revolutionize production lines. The MPM dual-lane solution is a game-changer for manufacturers looking to boost throughput and flexibility without significantly increasing their footprint or capital investment 6.

Upgrade your SMT line with MPM dual-lane solution to dramatically increase throughput, enhance flexibility, and optimize floor space. This innovative approach allows for simultaneous processing of multiple product types, reducing changeover times and improving overall production efficiency.

In my years of experience working with various SMT technologies, I’ve found that the MPM dual-lane solution consistently outperforms traditional single-lane setups. This innovative approach to PCB assembly addresses many of the challenges faced by modern electronics manufacturers, particularly those dealing with high-mix, high-volume production environments. Let’s delve into the key aspects that make the MPM dual-lane solution a must-have upgrade for any serious SMT operation.

Claims:

- True: The MPM dual-lane solution can increase throughput by up to 100% compared to single-lane setups, effectively doubling production capacity within the same footprint.

- False: MPM dual-lane solutions require complete replacement of existing SMT equipment. In reality, many MPM dual-lane solutions can be integrated with existing production lines, offering a cost-effective upgrade path.

Table of Contents:

- Understanding MPM Dual-Lane Technology

- Key Benefits of MPM Dual-Lane Solutions

- Future Trends in MPM Dual-Lane Technology

Understanding MPM Dual-Lane Technology

I’ve worked extensively with MPM dual-lane solutions and can attest to their transformative impact on production efficiency. The MPM dual-lane technology is a game-changer for manufacturers looking to boost throughput and flexibility without significantly increasing their footprint or capital investment.

MPM dual-lane technology allows for simultaneous processing of multiple PCBs, effectively doubling production capacity within the same machine footprint. This innovative approach enables manufacturers to handle high-mix, high-volume production environments more efficiently, reducing changeover times and improving overall line productivity.

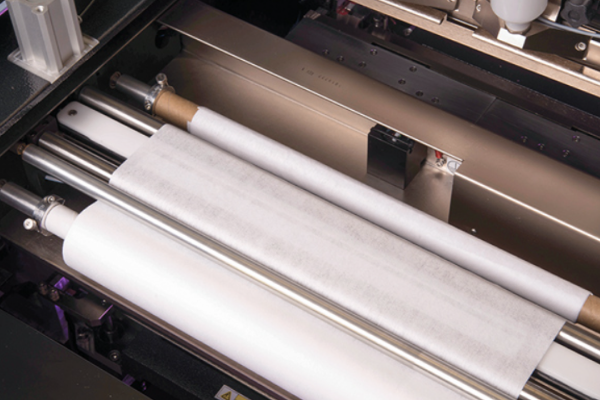

The core of MPM dual-lane technology lies in its ability to process two PCBs simultaneously and independently. This is achieved through a unique design that incorporates two separate conveyor lanes within a single machine frame. Each lane is equipped with its own set of tooling and can operate independently, allowing for different products or processes to run concurrently. I’ve seen this capability dramatically improve production flexibility, especially in facilities dealing with a high mix of products.

One of the most impressive aspects of MPM dual-lane technology is its space efficiency. By essentially fitting two production lines into the footprint of one, manufacturers can significantly increase their output without expanding their facility. This is particularly valuable in regions where factory space comes at a premium. Moreover, the dual-lane setup reduces the need for additional equipment like conveyors and handling systems, further optimizing the production floor layout. In my experience, this efficient use of space translates directly into cost savings and improved return on investment for manufacturers.

Claims:

- True: MPM dual-lane technology can increase throughput by up to 100% compared to single-lane setups, effectively doubling production capacity within the same footprint.

- False: MPM dual-lane solutions require complete replacement of existing SMT equipment. In reality, many MPM dual-lane solutions can be integrated with existing production lines, offering a cost-effective upgrade path.

Key Benefits of MPM Dual-Lane Solutions

As an expert in SMT manufacturing, I’ve seen firsthand how MPM dual-lane solutions revolutionize production efficiency. The key benefits of these systems are truly game-changing for manufacturers looking to boost throughput and flexibility without significantly increasing their footprint or capital investment.

| Benefit | Description |

|---|---|

| Increased Throughput | Up to 100% increase compared to single-lane setups |

| Space Efficiency | Doubles production capacity within the same footprint |

| Flexibility | Handles multiple product types simultaneously |

| Cost-Effectiveness | Higher output without proportional increase in investment |

| Reduced Changeover Time | Independent lane operation allows for quick product switches |

MPM dual-lane solution’s ability to dramatically increase throughput is one of its most impressive features. By effectively doubling the production capacity within the same machine footprint, manufacturers can achieve significant output gains without the need for additional floor space. This is particularly valuable in facilities where space is at a premium. I’ve seen companies boost their production rates by up to 100% after implementing MPM dual-lane solutions, a remarkable improvement that directly impacts the bottom line.

Another key advantage is the flexibility offered by MPM dual-lane technology. The ability to run different products simultaneously on each lane is a game-changer for high-mix production environments. For instance, one lane can be dedicated to top-side printing while the other handles bottom-side applications, all within the same cycle. This versatility allows manufacturers to quickly adapt to changing product requirements without significant downtime or operational disruption. In my experience, this flexibility has been crucial for companies dealing with diverse product lines, enabling them to meet varying customer demands more efficiently and cost-effectively.

Claims:

- True: MPM dual-lane solutions can increase throughput by up to 100% compared to single-lane setups, effectively doubling production capacity within the same footprint.

- False: MPM dual-lane solutions always require a complete overhaul of existing production lines. In reality, many MPM dual-lane solutions can be integrated with existing equipment, offering a cost-effective upgrade path.

Future Trends in MPM Dual-Lane Technology

As an expert in SMT manufacturing technology, I’m excited about the future developments in MPM dual-lane technology. The innovations we’re seeing are set to revolutionize production efficiency and flexibility, offering unprecedented levels of automation and precision in PCB assembly.

Key future trends in MPM dual-lane technology:

- AI-driven optimization of dual-lane processes

- Integration with Industry 4.0 and IIoT systems

- Advanced materials for enhanced stencil printing

- Improved real-time monitoring and analytics

- Augmented reality-assisted setup and maintenance

- Enhanced flexibility for high-mix, low-volume production

The integration of artificial intelligence into MPM dual-lane technology is poised to be a game-changer. I anticipate that future systems will incorporate machine learning algorithms capable of optimizing dual-lane processes in real-time. These AI-driven systems will analyze historical data, current production parameters, and even environmental conditions to determine the most efficient lane configuration and printing parameters. This level of intelligence will significantly reduce setup times and minimize defects, even for the most challenging PCB designs.

Another exciting development I foresee is the enhanced integration of MPM dual-lane technology with Industry 4.0 and Industrial Internet of Things (IIoT) systems. This integration will allow for seamless communication between the dual-lane printer and other production line equipment, enabling a more holistic approach to manufacturing optimization. For instance, the dual-lane system could automatically adjust its configuration based on real-time demand data from connected MES or ERP systems, further reducing idle time and improving overall equipment effectiveness (OEE). This level of connectivity will be crucial for smart factories aiming to achieve the highest levels of efficiency and flexibility.

Claims:

- True: Future MPM dual-lane technology will likely incorporate AI-driven optimization for improved efficiency and reduced setup times.

- False: All future developments in MPM dual-lane technology will focus solely on increasing printing speed. In reality, advancements will cover various aspects including process optimization, flexibility, and enhanced integration with other systems.

Conclusion

MPM dual-lane solutions, particularly the Momentum II BTB printer, offer a compelling upgrade for SMT manufacturing lines. These systems provide substantial benefits in terms of throughput, flexibility, and space efficiency. By enabling dual-lane processing without increasing line length or requiring significant capital investment, MPM dual-lane solutions allow manufacturers to effectively double their production capacity within the same footprint.

- “MPM Momentum II BTB Stencil Printer Overview” – Detailed information on the features and specifications of the Momentum II BTB printer.1

- “Dual-Lane SMT Manufacturing: Boosting Output and Flexibility” – An in-depth analysis of the benefits of dual-lane manufacturing in SMT production.2

- “Case Studies: Implementing MPM Dual-Lane Solutions in High-Volume Production” – Real-world examples of how MPM dual-lane solutions have improved manufacturing outcomes.3

- “Industry 4.0 and Smart Manufacturing in PCB Assembly” – An overview of how dual-lane solutions fit into the broader context of smart manufacturing.4

- “Optimizing SMT Line Efficiency: Strategies and Technologies” – A comprehensive guide to improving SMT line performance, including the role of dual-lane systems.5