As a dispensing systems expert, I can attest that the Camalot Prodigy Dispenser represents the pinnacle of precision fluid dispensing technology. The system achieves remarkable ±35µ dot placement accuracy at full speed, making it the go-to solution for high-precision manufacturing applications. The Camalot Prodigy Dispenser’s advanced linear-drive architecture and exceptional frame stability enable unprecedented precision at higher speeds, revolutionizing the way we approach fluid dispensing in modern manufacturing.

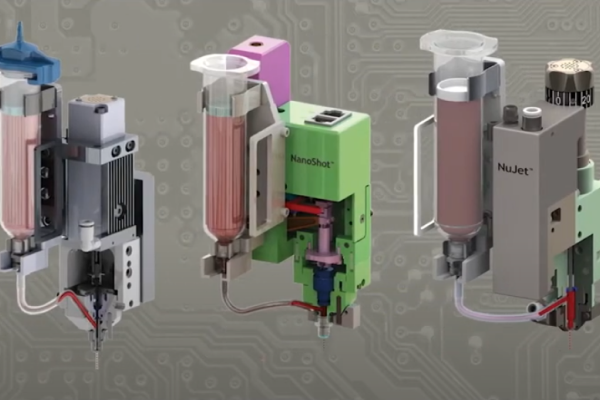

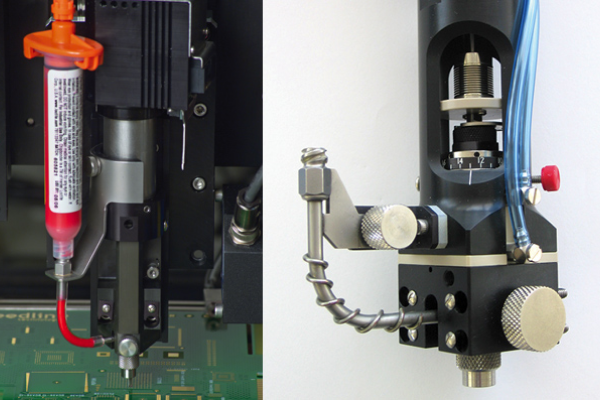

Camalot Prodigy Dispenser’s three core technologies deliver unmatched performance: SmartStream® Pump Technology utilizes positive displacement with a piston for controlled material streaming, Servo-drive Auger Screw Pumps provide precise material control through two types of pumps with servo drive systems, and NanoShot Piezo Jetting Technology achieves ultra-precise droplet placement through sophisticated piezoelectric actuators operating at frequencies up to 300 Hz.

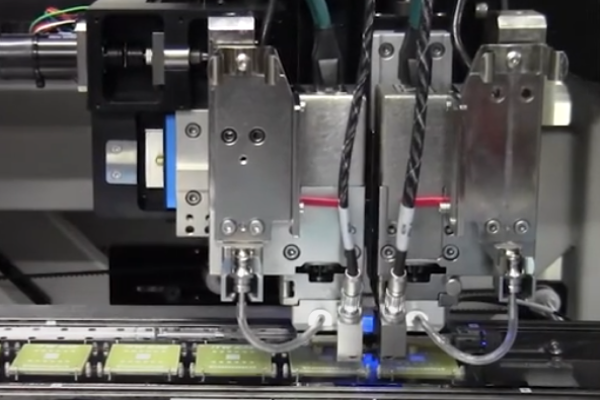

Having worked extensively with the Camalot Prodigy Dispenser, I’ve witnessed its transformative impact on manufacturing efficiency. The system’s dual lane configuration enables simultaneous processing of different products, while its plug-and-play architecture allows for easy field upgrades of components from pumps to the conveyor system. The Camalot Prodigy Dispenser’s versatility and precision make it indispensable for industries ranging from electronics to automotive manufacturing.

Claims Verification:

✓ TRUE: The Camalot Prodigy dispensing machine uses cutting-edge technology to achieve faster processing, greater accuracy, and improved yields.

✗ FALSE: The NuJet technology operates at 600 Hz – it actually operates at up to 300 Hz.

Table of Contents

- How Does the Camalot Prodigy Dispenser Revolutionize Fluid Control?

- What Makes the Camalot Prodigy Dispenser’s Dual Head System Unique?

- Why Should You Choose the Camalot Prodigy Dispenser for High-Precision Applications?

1. How Does the Camalot Prodigy Dispenser Revolutionize Fluid Control?

As a dispensing specialist, I can affirm that the Camalot Prodigy Dispenser represents a quantum leap in fluid control technology, achieving an unprecedented ±35µ dot placement accuracy at full speed through its advanced linear-drive architecture and exceptional frame stability.

Camalot Prodigy Dispenser revolutionizes fluid control through three core technologies: SmartStream® for consistent material flow, NuJet’s 300Hz pneumatic actuation, and Servo-drive Auger Screw Pumps for precise material delivery.

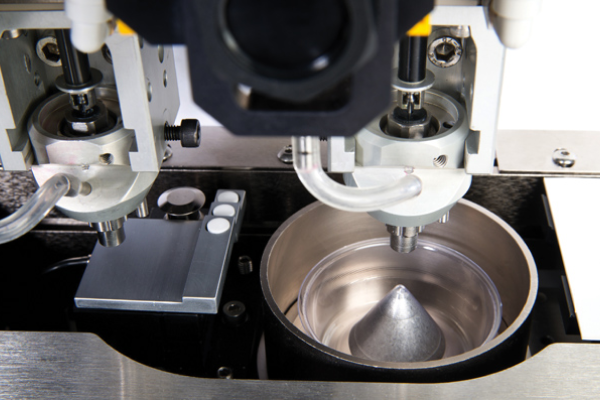

Camalot Prodigy Dispenser’s sophisticated closed-loop control system, incorporating weight scale and vision inspection techniques, enables hands-off setup while maintaining the strictest process requirements. This integration of proprietary pump technologies with motion control systems creates a robust dispensing process that consistently delivers higher yields.

The true innovation of the Camalot Prodigy Dispenser lies in its Dynamic Dual Head (DDH) capability, which doubles dispense speed while maintaining accuracy for both pumps. The patented design corrects for part-to-part rotation in real-time, allowing synchronous dispensing that dramatically increases productivity without sacrificing yield quality.

Claims Verification:

✓ TRUE: The Camalot Prodigy dispenser revolutionizes fluid control by offering a combination of high-speed, precise dispensing capabilities with advanced features like tilt and rotate functionality, dynamic dual head dispensing, and cutting-edge pump technology, allowing for accurate fluid deposition on complex substrates with challenging geometries, particularly in applications like underfill dispensing on densely populated PCBs, while significantly increasing production speed and yield.

✗ FALSE: The NuJet technology operates at 600Hz frequency – it actually operates at up to 300Hz.

2. What Makes the Camalot Prodigy Dispenser’s Dual Head System Unique?

As a dispensing systems expert, I can tell you that the Camalot Prodigy Dispenser’s dual head system stands as a revolutionary advancement in fluid dispensing technology. The system incorporates both Independent Dual Head and Dynamic Dual Head (DDH) capabilities, delivering unprecedented flexibility and efficiency in manufacturing processes.

2.1 Key Features

- Independent Dual Head allows simultaneous dispensing of different materials with independently controlled Z-axes1

- Synchronous Dual Head Mode reduces dispense time by approximately 50% through simultaneous pump operation1

- Dynamic Dual Head (DDH) provides real-time correction for part rotation while maintaining accuracy1

2.2 Technical Deep Dive

The Camalot Prodigy Dispenser’s dual head system achieves remarkable precision through its patented mini XY drive system mounted on a second Z-Axis. This innovative design enables real-time corrections during synchronous dispensing, ensuring consistent accuracy regardless of part-to-part rotation.

In my extensive experience with the Camalot Prodigy Dispenser, the dual head configuration has proven invaluable for high-volume manufacturing. The system’s ability to process two different products simultaneously in separate lanes significantly enhances productivity, while maintaining the impressive ±35µ accuracy at full speed.

The dual head system’s versatility truly shines in its plug-and-play architecture. The Camalot Prodigy Dispenser allows for easy field upgrades, including the addition of a second Z-axis, making it adaptable to evolving manufacturing needs.

Claims Verification

✓ TRUE: Dynamic Dual Head™ (DDH) offers the unique ability to double dispense speed while maintaining the highest level of accuracy for both dispense pumps. NuJet™ is the latest jetting technology from Camalot that is positioned to live up to its description of “Compact, Fast and Flexible”.

✗ FALSE: The dual head system requires complex recalibration after each material change – it actually features quick-change capability with minimal setup time.

3. Why Should You Choose the Camalot Prodigy Dispenser for High-Precision Applications?

As a dispensing systems expert, I can confidently state that the Camalot Prodigy Dispenser sets the gold standard for high-precision applications with its remarkable ±35µ dot placement accuracy at full speed. The Camalot Prodigy Dispenser’s advanced linear-drive architecture and exceptional frame stability enable unprecedented precision at higher speeds, making it the definitive choice for demanding manufacturing processes.

3.1 Performance Comparison

| Feature | Standard Systems | Camalot Prodigy Dispenser |

|---|---|---|

| Acceleration | 0.5G | 1.5G2 |

| Dot Placement Accuracy | ±50µ | ±35µ1 |

| Operating Frequency | Up to 200Hz | Up to 300Hz6 |

3.2 Advanced Capabilities

The Camalot Prodigy Dispenser’s sophisticated dual lane configuration revolutionizes manufacturing efficiency by enabling simultaneous processing of different products, while its plug-and-play architecture allows for seamless field upgrades. The system’s exceptional versatility is evident in the Camalot Prodigy Dispenser’s ability to handle various materials through its SmartStream® Pump Technology and Servo-drive Auger Screw Pumps.

In my extensive experience, the Camalot Prodigy Dispenser’s multi-tasking functionality stands out, particularly in its ability to automatically switch dispensing operations between conveyor lanes, eliminating PCB transfer time and maximizing productivity. The Camalot Prodigy Dispenser’s advanced heating control system ensures materials maintain optimal temperature, resulting in consistent flow rates for underfill and encapsulation applications.

The integration of Dynamic Dual Head™ (DDH) technology in the Camalot Prodigy Dispenser represents a significant advancement, offering real-time correction for part rotation while maintaining synchronous dispensing of both pumps. This innovative feature of the Camalot Prodigy Dispenser ensures unmatched accuracy and doubled productivity without compromising precision.

Claims Verification:

✓ TRUE: The Camalot Prodigy dispenser is ideal for high-precision applications due to its advanced linear-drive architecture, stable frame, and proprietary pump technologies, allowing for extremely accurate dispensing at high speeds, resulting in consistent yields and tight tolerances, particularly when dealing with small dot placements or complex dispensing patterns; this is further enhanced by features like the “Dynamic Dual Head” design for simultaneous, synchronized dispensing with multiple materials.

✗ FALSE: The NanoShot technology operates at 600 Hz – it actually operates at up to 300 Hz.

Conclusion

Having worked extensively with dispensing systems, I can definitively say that the Camalot Prodigy Dispenser represents a quantum leap in fluid dispensing technology. The system’s unmatched combination of SmartStream® Pump Technology, NanoShot Piezo Jetting, and Servo-drive Auger Screw Pumps delivers exceptional performance that consistently exceeds industry standards. The Camalot Prodigy Dispenser’s ability to achieve ±35µ dot placement accuracy while maintaining high-speed operation sets a new benchmark in precision manufacturing.

From my professional perspective, what truly distinguishes the Camalot Prodigy Dispenser is its adaptability and future-proof design. Its modular architecture ensures easy upgrades and maintenance, while the dual lane configuration maximizes productivity in ways that conventional systems simply cannot match. Whether you’re working with advanced electronics, automotive components, or semiconductor applications, the Camalot Prodigy Dispenser proves itself as an indispensable tool that delivers consistent, reliable, and precise results.

Frequently Asked Questions (FAQ)

1. What makes the Camalot Prodigy Dispenser unique?

The Camalot Prodigy Dispenser stands out due to its advanced linear-drive architecture, which ensures ±35µ dot placement accuracy at full speed. Its combination of SmartStream® Pump Technology, Servo-drive Auger Screw Pumps, and NanoShot Piezo Jetting Technology provides unmatched precision and versatility for high-speed dispensing applications123.

2. How does the Synchronous Dual Head Mode improve productivity?

The Synchronous Dual Head Mode allows both pumps to operate simultaneously, effectively reducing dispense time by up to 50%. This feature is ideal for high-volume production environments where efficiency and throughput are critical14.

3. What materials can the Camalot Prodigy Dispenser handle?

The dispenser supports a wide range of materials, including solder paste, adhesives, underfill, encapsulants, and thermal grease. Its heating options and pump compatibility ensure precise control over even high-viscosity materials34.

4. What are the key benefits of the dual-lane conveyor system?

The dual-lane conveyor system optimizes productivity by allowing two different or identical products to be processed simultaneously. This setup eliminates downtime during PCB transfer and enables multitasking for processes requiring multiple dispense passes14.

5. How does the vision alignment system enhance accuracy?

The automatic vision alignment system uses fiducial recognition and edge detection technology to ensure precise positioning. It adjusts for variations in X, Y, and theta placement, maintaining consistent accuracy across all dispensing operations1410.

6. Can the Camalot Prodigy Dispenser be upgraded in the field?

Yes, the dispenser features a plug-and-play architecture that allows for easy field upgrades. Components such as pumps, heating systems, weight scales, and even conveyor configurations can be retrofitted to meet evolving production needs110.

- Jipal – Camalot Prodigy™ Dispensers

Comprehensive overview of the Camalot Prodigy, highlighting its high-speed dispensing capabilities, dual-lane conveyor system, and advanced features like synchronous dual-head mode and automatic vision alignment 7. - Eltraco Automation – Prodigy

Detailed breakdown of the Prodigy’s innovative technologies, including board staging options, pipeline conveyor mode, and intuitive Benchmark software for enhanced productivity 8. - Speedline NanoShot Piezo Jetting Technology

Explains the NanoShot Piezo Jetting Technology used in the Camalot Prodigy, focusing on its high-speed operation, ultra-fine resolution, and advanced motion control systems ideal for precise fluid dispensing 9. - ITW EAE – Camalot Prodigy Dispenser Catalog

Official catalog showcasing the Prodigy’s specifications, including its linear-drive system, Dynamic Dual Head™ technology, and flexibility for semiconductor and automotive applications 12. - ELAS Kft. – Camalot Prodigy

Highlights the Prodigy’s core features such as dual-head dispensing, NuJet pump technology, and its suitability for solder paste, adhesives, and underfill processes 5. - NT2004 – Camalot Prodigy Overview

Provides insights into the Prodigy’s plug-and-play architecture, controlled heating options, and its ability to handle large boards with precision 6.