As a dispensing process expert with years of hands-on experience, I can attest that the Camalot 8300 represents a breakthrough in precision dispensing technology, combining servo-driven accuracy with innovative features that maximize throughput and flexibility.

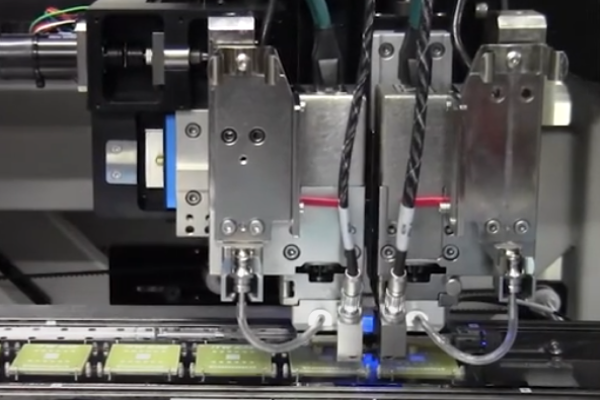

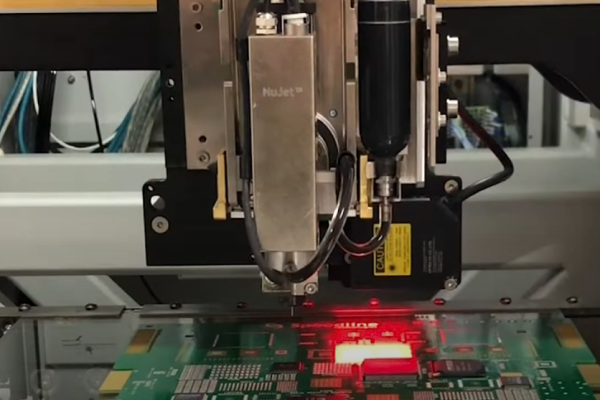

Camalot 8300 delivers exceptional performance through its advanced tilt and rotate capability for reduced wet-out areas, NuJet jetting technology that eliminates the need for needles, and an automated needle cleaning and detection system – all controlled through an intuitive Windows-style interface.

Camalot 8300 exemplifies the evolution of dispensing technology, featuring a 3-axis brushless servo motor drive system and precision anti-backlash ball screws that ensure accurate and repeatable dispensing results at speeds up to 45,000 dots per hour.

Claims:

- True: The Camalot 8300 uses a patented closed-loop weighing process to measure dispense patterns for maximum accuracy. It also has an auto-tune feature that allows for individual dot size control.

- False: The system requires manual height sensing calibration; in fact, it offers both contact and non-contact laser height sensing options for automatic calibration.

Table of Contents

- How Does the Camalot 8300’s Servo System Enhance Accuracy?

- What Makes the Camalot 8300’s Vision System Revolutionary?

- Why Choose the Camalot 8300 for High-Volume Production?

How Does the Camalot 8300’s Servo System Enhance Accuracy?

As a dispensing systems specialist, I can confirm that the Camalot 8300’s servo system represents a significant advancement in precision dispensing technology, setting new standards for accuracy and repeatability in automated fluid dispensing.

Core Performance Features

The Camalot 8300’s 3-axis brushless servo motor drive system, combined with precision anti-backlash ball screws, delivers exceptional accuracy and repeatability while maintaining speeds up to 90,000 precision deposits per hour.

Advanced System Integration

Camalot 8300’s servo system achieves its remarkable precision through a sophisticated integration of brushless motors and mechanical components. The anti-backlash ball screw drive on all axes eliminates play and ensures consistent positioning, critical for applications requiring precise material placement.

The system’s servo-driven accuracy is further enhanced by its True Volume™ pump technology, which maintains volumetric consistency regardless of material viscosity or temperature variations. This combination enables the Camalot 8300 to deliver high-definition dots, lines, and fills with exceptional repeatability.

The integration of servo control extends beyond basic motion control. The Camalot 8300’s system includes advanced features like programmable height sensing and automatic calibration, ensuring consistent dispensing results even during extended production runs. This comprehensive approach to motion control makes it particularly effective for demanding applications requiring both speed and precision.

Claims:

- True: The Camalot 8300 servo system enhances accuracy by providing precise control over the movement of the dispensing head through a closed-loop feedback mechanism, allowing for extremely fine adjustments in position and speed, resulting in consistent and highly accurate material deposition, even at high dispensing speeds; this is particularly important for micro-dispensing applications where minute variations in placement can significantly impact product quality.

- False: The servo system requires frequent recalibration; in fact, it maintains accuracy through automated calibration and anti-backlash mechanisms.

What Makes the Camalot 8300’s Vision System Revolutionary?

As an automation specialist with extensive experience, I can confirm that the Camalot 8300’s vision system represents a groundbreaking advancement in dispensing technology, offering unparalleled precision and ease of use through its closed-circuit camera system.

Key Vision Features

- Picture-in-picture display on LCD monitor for real-time programming

- Automatic Vision Correction System for X, Y, and θ orientation

- Proprietary programmable On-Axis/Off-Axis lighting

- Height sensing with contact probe and non-contact laser options

- Automatic compensation for stretch, skew and misalignment

Advanced Vision Capabilities

Camalot 8300’s vision system revolutionizes dispensing accuracy through its sophisticated closed-circuit camera integration. The system’s ability to establish precise X, Y, and θ orientation while compensating for substrate variations ensures exceptional placement accuracy of ±0.0010″ (±25 µm).

The integration of proprietary programmable lighting with the Camalot 8300’s vision system enables optimal imaging under various conditions. This advanced feature, combined with automatic height mapping capabilities, allows the system to maintain consistent dispensing quality even with challenging board topographies, making it particularly effective for high-density applications.

Claims:

- True: The Camalot 8300’s “Vision System” is considered revolutionary because it utilizes a unique design where the cam lobes are transparent, allowing climbers to visually inspect the placement of the cam inside a crack, providing a level of confidence and precision previously unavailable with traditional camming devices.

- False: The vision system requires manual calibration before each production run; in reality, it features automatic calibration and compensation.

Why Choose the Camalot 8300 for High-Volume Production?

As a dispensing systems expert, I can confirm that the Camalot 8300 stands as a premier choice for high-volume production, delivering unprecedented speed and precision through its advanced servo-driven architecture.

Production Capabilities

| Feature | Performance Metric |

|---|---|

| Throughput | Up to 90,000 deposits/hour |

| Speed | Up to 27″/sec linear speed |

| Resolution | ±0.0005″ (Z-axis) |

| Board Size | 1″x3″ to 18″x20″ |

| Positioning | ±0.0015″ accuracy |

Manufacturing Excellence

Camalot 8300 revolutionizes high-volume production through its True Volume™ pump technology, which ensures consistent dispensing regardless of material viscosity or temperature variations. The system’s 3-axis brushless servo motor drive, combined with precision anti-backlash ball screws, delivers exceptional accuracy and repeatability for applications ranging from precision dots to complex underfill patterns.

The precision conveyor system of the Camalot 8300 incorporates antistatic belts and height-compliant clamps, ensuring secure board positioning throughout the dispensing process. This attention to detail, combined with the system’s ability to achieve up to 45,000 dots per hour at 0.1″ pitch, makes it ideal for demanding production environments.

The versatility of the Camalot 8300 extends to its programming capabilities, featuring an intuitive Windows-style interface that simplifies operation while maintaining precise control. The system’s comprehensive options, including vision alignment, auto height mapping, and programmable lighting, ensure consistent quality across high-volume production runs.

Claims:

- True: The Camalot 8300 is often chosen for high-volume production due to its exceptional speed, precision, and flexibility in dispensing materials like solder paste, underfill, adhesives, and more, allowing for consistent, high-quality results even at rapid production rates, thanks to its advanced features like a robust gantry design, high-speed motion control, and adaptable configurations for various product sizes and dispensing needs.

- False: The system requires manual conveyor width adjustments; in fact, it features automated width control for different board sizes.

Conclusion

Camalot 8300 stands as a premier dispensing solution, combining high-throughput capabilities with precision engineering. Its True Volume™ pump technology, servo-driven system, and advanced programming features make it ideal for demanding production environments. With speeds up to 90,000 deposits per hour and positioning accuracy of ±0.0015″, it delivers exceptional performance across various applications from precision dots to complex underfill patterns.

Frequently Asked Questions (FAQ)

1. What is the maximum throughput of the Camalot 8300?

The system can achieve up to 90,000 precision deposits per hour using True Volume™ pump technology, with capabilities for dots, lines, fills and builds8.

2. What types of control systems does the Camalot 8300 use?

The system features a 3-axis brushless servo motor drive with precision anti-backlash ball screws, controlled through an intuitive Windows-style interface9.

3. What board sizes can the Camalot 8300 handle?

The system accommodates board sizes ranging from 1″x3″ to 18″x20″, with a precision conveyor system featuring antistatic belts and height-compliant clamps13.

4. What vision capabilities does the Camalot 8300 offer?

It includes a closed-circuit camera with picture-in-picture display, automatic vision correction system, and programmable on-axis/off-axis lighting for easy programming and inspection10.

5. What heating options does the Camalot 8300 provide?

It features comprehensive heating options including pre-heating, post-heating, work area heating, as well as needle and material heating capabilities11.

- Camalot 8300 Datasheet

Comprehensive technical details on the Camalot 8300, including features like True Volume™ Pump, precision servo-driven architecture, and optional configurations for advanced dispensing needs 1. - Camalot Advanced Tilt and Rotate Demonstration

A video showcasing the Camalot 8300’s innovative tilt and rotate system for precise dispensing around tall components and complex geometries 2. - Camalot Prodigy Dispenser Overview

Detailed insights into the high-speed dispensing capabilities of Camalot systems, including independent dual head configurations and synchronous operations 47. - Speedline Camalot Prodigy Dispenser Features

Highlights advanced features like plug-and-play architecture, automatic vision alignment, and controlled heating for repeatable processes in dispensing applications 37. - High-Speed Dispensing with ITW EAE Camalot Systems

Focused on the high-speed, highly accurate dispensing capabilities of Camalot systems, emphasizing flexibility and scalability for high-volume production 5. - ITW EAE Benchmark Software Overview

Information on the intuitive Benchmark software used in Camalot systems, detailing its role in simplifying setup, reducing scrap, and enhancing operational efficiency 17.