As a process engineer specializing in SMT equipment, I understand the challenges of selecting the right Squeegee Blades and Holders for MPM Momentum printers. The wrong choice can lead to inconsistent print quality, paste bleeding, and reduced throughput in your production line.

Selecting optimal Squeegee Blades and Holders for MPM Momentum comes down to three critical factors: blade holder assembly type, blade material selection, and mounting mechanism. The Momentum series offers specialized assemblies like the 1023036-xxx series with spring-loaded floating side dams for superior paste control.

In my years of optimizing MPM Momentum printer performance, I’ve found that the right combination of precision-machined aluminum holders and application-specific blades consistently delivers exceptional results. The latest Squeegee Blades and Holders for MPM Momentum feature advanced designs with closed-loop pressure control, ensuring precise and repeatable printing performance across various component sizes.

Table of Contents

- Configure Squeegee Blades and Holders for MPM Momentum

- Match Blade Materials to Your MPM Momentum Application

- Conclusion

- Frequently Asked Questions

1. Configure Squeegee Blades and Holders for MPM Momentum

As an expert in SMT printing processes, I know that configuring squeegee blades and holders for MPM Momentum printers is critical to achieving consistent print quality. Misaligned or improperly selected components can lead to paste bleeding, poor aperture fill, and reduced production efficiency.

1.1 Available Blade Assemblies and Part Numbers

MPM Momentum squeegee blade assemblies are available in several sizes and configurations. Common part numbers include:

| ITW EAE Squeegee Matrix – 25th November 2024 | ||

| Mpm Printer Machine Type | Metal Blade Holder Assemblies | |

| Edison | 2009242 (FP50 Quick Mounting SQ Holder) | 1019822 |

| Length (mm): 250, 300,350,400,450,500,550,610 | ||

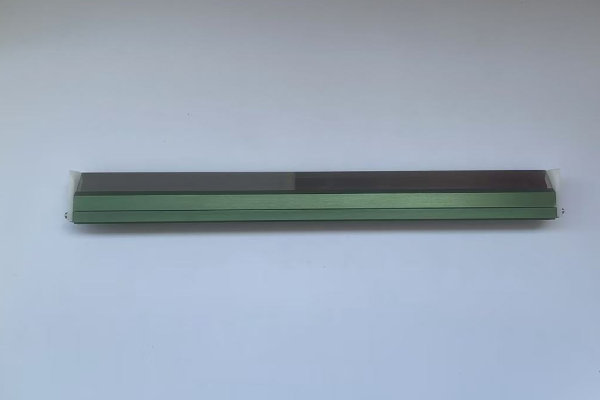

| Momentum II | 2006180 Green (FP100 Quick Mounting SQ Holder) | 1019822 |

| 2006150 (FP100 Quick Mounting SQ Holder) | ||

| Length (mm): 200, 250, 300, 350, 400, 450, 500, 550 & 610 | ||

| Edison | 2006180 Green (FP100 Quick Mounting SQ Holder) | 1019822 |

| 2006150 (FP100 Quick Mounting SQ Holder) | ||

| Length (mm): 200, 250, 300, 350, 400, 450 | ||

| Machine Type | Metal Blade Holder Assemblies | |

| Edison | 1024142 (Quick Mounting SQ Holder), 45 。 | 1017331 |

| Length (mm): 200, 250, 300, 350, 400, 450 | ||

| Momentum | 2005946 Green (Spring Loaded Side Dam)(FP100 SQ Holder) | 1019822 |

| 1023036 (Spring Loaded Side Dam)(FP100 SQ Holder) | ||

| Length (mm): 200, 250, 300, 350, 400, 450, 500, 550 & 610 | ||

| Momentum | 1019814 , Green (Spring Loaded S. Dam)(FP55 SQ Holder) | 1019822 |

| 1019813 (Spring Loaded S. Dam)(FP55 SQ Holder) | ||

| Length (mm): 165, 220, 300, 360, 420, 430, 450, 460, 520 & 608 | ||

| Machine Type | Metal Blade Holder Assemblies | |

| 1018961 , Green (Spring Loaded Side Dam)(with kit 1017192 | ||

| 1018140 (Spring Loaded Side Dam)(with kit 1017192 ) | ||

| Momentum | Length (mm): 165, 220, 250 , 300, 360, 420, 430, 450, 460, 520 & 608 | 1017331 |

| Machine Type | SPEEDLINE Metal Blade Holder Assemblies | |

| Accuflux | 1006638 | 1013667 |

| Length (mm): 150, 220, 300, 360, 420, 430, 450, 460, 520 & 608 | ||

| Accela | 1012570 (Spring Loaded S.Dam from Rev. D)(with blade 1017776 only) | 1017776 |

| 1013666 | ||

| Length (Inches): 06, 08,10, 12, 14, 16, 19, 21, 22 & 24 | ||

| AP, UP2000 & UP3000 | 1011133 (Programmable Head) | 1013666 |

| Length (Inches): 08,10, 12, 14, 16, 19, 21, 22, 24 & 27 | ||

| Mpm Printer UP2000 & SPM | 1006110 (Standard Head) | 1013666 |

| Length (Inches): 08,10, 12, 13, 14, 16, 19, & 20.5 | ||

These options ensure compatibility with various applications, from fine-pitch devices to larger components.

1.2 Proposals for Optimal Configuration

- Choose the Right Holder Type: For high precision and reduced paste waste, opt for blade holders with spring-loaded floating side dams, such as the 1023036 assembly. These help maintain paste within the blade area, minimizing bleed-out during printing.

- Match Blade Material to Application: Use lead-free blades for environmentally compliant processes or premium metal blades for high durability. Polyurethane blades are ideal for softer stencil materials or specific applications requiring lower pressure settings.

- Optimize Mounting Mechanisms: For frequent changeovers, Quick Release assemblies like the 2006150 series are recommended. For more stable operations, knob-screw assemblies such as the 1018140 provide reliable performance with minimal adjustments.

By carefully configuring these elements based on your production needs, you can enhance print accuracy and efficiency while reducing downtime.

Claims:

- True: The following blade holder assemblies are similar with each other except on how they are secured to the print head. 1018140 & 1024009 are the same (knob and screw mounting). 1023036 & 2006150 are the same (Quick Release mounting)

- False: All MPM Printer Momentum blade holders use Quick Release mounting (Knob-screw mounting is also available).

2. Match Blade Materials to Your MPM Momentum II Application

Selecting the right Squeegee Blades and Holders for MPM Momentum II can dramatically improve your print quality, reduce defects, and extend maintenance intervals. The proper blade material choice directly impacts your production yield and operational efficiency.

2.1 Material Options

For MPM Momentum II applications, three primary blade materials are available: polyurethane blades for stepped stencil applications, premium metal blades for mixed component boards, and lead-free blades for environmentally compliant processes.

2.2 Implementation Strategy

Polyurethane Squeegee Blades and Holders for MPM Momentum II offer exceptional print deposition and dimensional stability. These blades excel in applications requiring solvent resistance and repetitive flexing, making them ideal for traditional mesh and emulsion screen printing.

Metal Squeegee Blades and Holders for MPM Momentum II provide superior performance for boards featuring both large and fine-pitch components. Their non-porous ductile coating enhances paste release and ensures easy cleaning, with a Rockwell rating of “RC/72” for exceptional durability.

For environmentally conscious operations, lead-free Squeegee Blades and Holders for MPM Momentum II maintain high performance while meeting compliance requirements. These green anodized aluminum holders are easily identifiable and available in both 60° and 45° printing angles.

Claims:

- True: Metal blades are ideal for boards featuring a mix of large and fine pitch components where panel flatness cannot be assured.

- False: All blade materials require special cleaning solutions (In fact, the non-porous coating makes cleaning straightforward).

3. Conclusion

To select squeegee blades and holders for MPM Momentum printers, focus on three key factors: blade assembly type, material, and mounting mechanism. Blade assemblies like the 1023036 (Quick Release) and 1018140 (Knob-Screw) offer reliable options for fine-pitch and larger device applications. Choose lead-free or premium metal blades for durability or polyurethane for softer stencils. Ensure compatibility with your production needs, whether high precision or frequent changeovers. By aligning these components with your specific requirements, you can achieve consistent print quality and operational efficiency.

4. Frequently Asked Questions

- What are the available squeegee blade assemblies for MPM Momentum printers?

The available assemblies include 300mm, 450mm, 530mm, 590mm, and 610mm blade sets. Part numbers include SMHA-457-LF for lead-free applications and SMFMI-300 for premium metal blades126. - What mounting options are available for squeegee holders?

MPM Momentum supports both knob-screw mounting (e.g., 1018140) and Quick Release systems (e.g., 1023036). These options allow flexibility based on application needs and ease of maintenance13. - Which blade materials are recommended for specific applications?

- How do I optimize squeegee pressure and angle settings?

Set squeegee pressure to approximately 500 grams per 25mm of blade length and maintain a 60° angle for most applications. Adjustments may be necessary for specific stencil or paste types to avoid smearing or scooping5.

External links recommendation:

- SMT Components – Squeegee Holders and Blades for MPM Printers

This resource provides detailed information on squeegee blade assemblies for MPM Momentum printers, including part numbers, blade holder types (e.g., 1023036 and 2006150), and their recommended applications, such as fine-pitch devices and larger components. - High-Tech Conversions – Squeegee Holders and Blades for MPM Momentum

Offers a comprehensive list of screw-mount holders and blades, including lead-free options, with detailed descriptions of sizes (e.g., SMHA-140-LF to SMHA-520-LF) and configurations for optimal use in SMT processes. - ITW EAE Support – Choosing a Squeegee Blade

This official ITW EAE document outlines the available squeegee blade assemblies for Momentum printers, their part numbers, and recommended uses, providing valuable insights into application-specific configurations. - SMT Industrial – MPM Momentum Plus Squeegee Blades & Holders

Features precision-machined aluminum holders and a wide range of blade sizes (8 to 24 inches), ideal for customizing your setup to meet specific production needs.