For decades, Speedline Camalot® has stood at the forefront of dispensing technology for electronic materials, establishing itself as a global leader in this vital sector. The company’s commitment to innovation has driven the development of advanced dispensing systems that cater to a wide range of applications—from board-level assembly to advanced packaging and the latest in compound semiconductors. Among its suite of products, the Prodigy Dispenser and the Prodigy Dual Lane Dispenser have emerged as standout solutions, combining precision, speed, and versatility to meet the evolving demands of the electronics manufacturing landscape.

The Evolution of Speedline Camalot Dispensing Technology

Speedline Camalot Dispensing technology has seen significant advancements over the years, paralleling the rapid evolution of electronic devices and components. Initially focused on simple adhesive applications, the scope of dispensing technology has expanded dramatically. Today, it encompasses a variety of materials, including solder paste, conductive adhesives, encapsulants, and potting compounds. As electronic components have become smaller and more complex, the demand for precise and reliable dispensing has increased, driving innovation in equipment design and functionality.

Speedline Camalot has been a pioneer in this transformation, offering solutions that not only enhance manufacturing efficiency but also ensure the reliability and performance of electronic assemblies. By integrating cutting-edge technologies and sophisticated control systems, Speedline has set a benchmark for quality and accuracy in the dispensing process.

The Speedline Camalot Prodigy Dispenser: Overview

The Prodigy Dispenser represents the pinnacle of Speedline Camalot’s dispensing technology. Engineered for high-performance applications, the Prodigy Dispenser is designed to deliver exceptional precision and consistency, making it an ideal choice for a variety of electronic materials.

Key Features

- Precision Control: The Speedline Camalot Prodigy Dispenser utilizes advanced servo motors and closed-loop feedback systems, ensuring that every dispense operation is executed with pinpoint accuracy. This level of control is crucial for applications where even the slightest deviation can lead to performance issues or failures in electronic devices.

- Versatility: Capable of dispensing a wide range of materials, including low-viscosity adhesives and high-viscosity pastes, the Speedline Camalot Prodigy Dispenser is suited for both prototyping and high-volume production environments. This versatility allows manufacturers to adapt to changing material requirements without the need for extensive reconfiguration.

- User-Friendly Interface: Speedline has prioritized ease of use in the Prodigy Dispenser’s design. The intuitive interface simplifies the programming process, allowing operators to set up dispense parameters quickly and efficiently. This reduces downtime and enhances overall productivity on the manufacturing floor.

- Advanced Software Solutions: The Speedline Camalot Prodigy Dispenser is equipped with sophisticated software that enables real-time monitoring and analysis of dispense operations. This data-driven approach helps identify potential issues before they escalate, ensuring a smooth production process and maintaining product quality.

- Compact Design: With a footprint designed to maximize space efficiency, the Speedline Camalot Prodigy Dispenser can be integrated seamlessly into existing production lines. This compact design does not compromise on functionality, making it a practical choice for manufacturers with space constraints.

The Prodigy Dual Lane Dispenser: Maximizing Efficiency

As manufacturing demands continue to grow, the need for faster and more efficient dispensing solutions has become paramount. The Prodigy Dual Lane Dispenser addresses this need by offering dual-lane capabilities that significantly increase throughput without sacrificing precision.

Key Features

- Dual Lane Configuration: The hallmark feature of the Speedline Camalot Prodigy Dual Lane Dispenser is its ability to operate two dispensing lanes simultaneously. This feature effectively doubles production capacity, making it an invaluable asset for high-volume manufacturing environments.

- Independent Control: Each lane of the Speedline Camalot Prodigy Dual Lane Dispenser can be independently controlled, allowing for different materials or dispensing patterns to be used simultaneously. This flexibility is particularly beneficial for manufacturers that require diverse applications within the same production run.

- Enhanced Workflow: By optimizing the dispensing process with dual lanes, manufacturers can achieve faster cycle times and reduced lead times. This enhanced workflow translates to increased productivity and improved operational efficiency.

- High-Quality Dispense: Despite the increased speed, the Speedline Camalot Prodigy Dual Lane Dispenser maintains the same high standards of precision and quality as its single-lane counterpart. This ensures that each dispense operation meets stringent quality control standards, critical for the reliability of electronic components.

- Scalability: The Speedline Camalot Prodigy Dual Lane Dispenser is designed with scalability in mind, allowing manufacturers to easily expand their dispensing capabilities as production needs grow. This adaptability ensures that the equipment remains relevant and effective in a rapidly changing market.

Applications Across Industries

The versatility of Speedline Camalot’s dispensing systems makes them suitable for a broad range of applications across various industries:

- Consumer Electronics: With the proliferation of smartphones, tablets, and wearables, the demand for precise adhesive dispensing has surged. The Speedline Camalot Prodigy Dispenser and Dual Lane Dispenser provide manufacturers with the capability to produce high-quality electronic devices efficiently.

- Automotive: The automotive industry increasingly relies on electronic components for features such as advanced driver-assistance systems (ADAS) and infotainment. Speedline’s dispensing technology ensures that these components are manufactured with the reliability required for automotive applications.

- Medical Devices: In the medical sector, precision and safety are paramount. Speedline’s dispensers are used to assemble medical devices that require stringent quality control and compliance with regulatory standards, making them a trusted choice in this critical field.

- Industrial Automation: As industries automate their processes, the need for reliable and efficient dispensing systems has become more pronounced. Speedline’s technology enables manufacturers to streamline operations and improve overall productivity.

Camalot Dispensing

Speedline Camalot has solidified its position as a leader in dispensing technology through its relentless pursuit of innovation and quality. The Prodigy Dispenser and Prodigy Dual Lane Dispenser exemplify the company’s commitment to delivering cutting-edge solutions that meet the complex needs of modern manufacturing.

As the electronics industry continues to evolve, the importance of precise and reliable dispensing technology will only grow. With its advanced features, user-friendly design, and adaptability, Speedline Camalot’s dispensing systems are well-equipped to meet the challenges of today and tomorrow. Whether for board-level assembly, advanced packaging, or compound semiconductor applications, Speedline Camalot remains a trusted partner for manufacturers striving for excellence in their dispensing processes.

Future Directions

Looking ahead, Speedline Camalot is poised to further revolutionize dispensing technology. As materials science advances and new formulations are developed, the company’s ongoing commitment to research and development will ensure that it remains at the cutting edge of the industry. Innovations such as artificial intelligence and machine learning are set to play a significant role in enhancing dispense accuracy and efficiency, positioning Speedline Camalot as a trailblazer in the ever-evolving landscape of electronic manufacturing.

With its strong foundation in quality, innovation, and customer service, Speedline Camalot is ready to lead the charge in shaping the future of dispensing technology for electronic materials, ensuring that manufacturers are equipped to meet the demands of an increasingly complex and competitive marketplace.

Underfill

Underfill technology has become an integral part of modern electronics manufacturing, particularly in the assembly of high-density packages and board-level assemblies. As devices shrink in size and increase in complexity, the need for reliable underfill solutions has never been greater. Speedline Camalot® dispense machines, particularly those featuring the SmartStream® pump technology, have established themselves as leaders in this domain, offering fast, efficient, and precise underfill dispensing across a variety of packages.

Understanding Underfill Technology

Underfill is a critical material used in the assembly of semiconductor devices. It is a polymer-based adhesive that is dispensed into the space between a chip and the substrate it is mounted on. The primary purpose of underfill is to provide mechanical stability to components, particularly in applications where thermal and mechanical stresses are prevalent.

Key Functions of Underfill

- Mechanical Support: Underfill acts as a buffer, absorbing mechanical stresses that can cause damage to sensitive components during thermal cycling or physical impacts.

- Thermal Management: By promoting better heat dissipation, underfill materials help maintain optimal operating temperatures for electronic components, reducing the risk of overheating and failure.

- Environmental Protection: Underfill materials often provide a barrier against moisture and contaminants, which can degrade performance and lead to premature failure of electronic devices.

- Improved Reliability: The addition of underfill enhances the overall reliability of electronic assemblies, particularly in high-performance applications such as automotive, telecommunications, and consumer electronics.

Applications of Underfill

Underfill is used in a wide range of electronic packages, including:

- Flip Chips: This package type involves mounting a chip upside down on a substrate, requiring precise underfill to fill the gap and provide support.

- Direct Chip Attach (DCA): In DCA applications, chips are attached directly to the board, necessitating effective underfill for stability and performance.

- Stacked Die Packages: These packages, which consist of multiple chip layers stacked on top of one another, require underfill to ensure reliable interconnections.

- Ball Grid Array (BGA) Components: BGAs have solder balls on their underside, and underfill is crucial to stabilize the connection between the component and the PCB.

Speedline Camalot: A Leader in Dispensing Technology

Overview of Speedline Camalot

Speedline Camalot has long been recognized as a leader in dispensing technology, particularly for electronic materials. The company’s commitment to innovation and quality has positioned its dispense machines as go-to solutions for manufacturers looking to enhance their production processes.

SmartStream® Pump Technology

At the heart of Speedline Camalot’s dispensing solutions is the SmartStream® pump technology. This advanced pumping system is designed to deliver precise and repeatable underfill dispensing, making it ideal for a variety of applications.

Key Features of SmartStream® Pump Technology

- High Accuracy: The SmartStream® pump technology ensures that underfill is dispensed with high accuracy, which is critical for applications requiring precise amounts of material.

- Fast Dispensing Speeds: Speedline Camalot machines equipped with SmartStream® technology can achieve high dispensing speeds, increasing throughput and reducing production cycle times.

- Consistency and Repeatability: The technology allows for consistent underfill application across multiple cycles, ensuring that every component is treated equally and reliably.

- Versatility: SmartStream® pumps can handle a wide range of underfill materials, from low-viscosity liquids to higher-viscosity adhesives, making them suitable for diverse manufacturing environments.

- Reduced Material Waste: The precision of the SmartStream® pump reduces overdispensing and minimizes waste, contributing to more sustainable manufacturing practices.

The Camalot Advantage

The use of Camalot dispense machines, particularly those with SmartStream® technology, offers numerous advantages for manufacturers looking to optimize their underfill processes.

- Enhanced Production Efficiency: With faster dispense speeds and improved accuracy, manufacturers can significantly enhance their production efficiency. This leads to shorter lead times and increased output.

- Lower Total Cost of Ownership: The combination of reduced material waste, improved accuracy, and high reliability translates to lower overall costs for manufacturers.

- Scalability: Speedline Camalot machines are designed to be scalable, allowing manufacturers to easily adapt to changing production demands without requiring extensive reconfiguration.

- Integration with Existing Systems: Camalot machines can be seamlessly integrated into existing manufacturing lines, providing an efficient upgrade path for manufacturers looking to enhance their capabilities.

- Robust Support and Service: Speedline Camalot offers comprehensive support and service to its customers, ensuring that machines are maintained at optimal performance levels throughout their lifespan.

The Underfill Process with Camalot Machines

Step-by-Step Overview

The underfill process using Speedline Camalot machines typically involves several key steps:

- Preparation: Before the dispensing process begins, the components and substrates must be properly prepared. This includes cleaning surfaces to remove any contaminants that could interfere with adhesion.

- Dispensing: Using the SmartStream® pump technology, underfill is dispensed into the designated area, filling the gaps between the chip and substrate. The precision of the Camalot machines ensures that the correct amount of material is applied.

- Flow and Cure: Once dispensed, the underfill flows under the component, ensuring complete coverage. After flowing, the material is cured according to the manufacturer’s specifications, solidifying and providing the necessary support.

- Inspection: After curing, the assembly is typically subjected to inspection processes to ensure that the underfill has been applied correctly and that there are no defects.

- Final Assembly: With the underfill cured and inspected, the component can proceed to the next steps in the assembly process, whether that involves additional components or testing.

Challenges and Solutions

While underfill technology is highly effective, several challenges can arise during the dispensing process. Speedline Camalot machines are designed to address these challenges effectively.

- Material Viscosity: Different underfill materials have varying viscosities, which can impact dispensing accuracy. The SmartStream® pump technology is adaptable, allowing for precise control over a wide range of material viscosities.

- Component Geometry: Complex geometries can pose challenges for underfill application. Camalot machines are equipped with advanced dispensing heads that can navigate intricate shapes and ensure complete coverage.

- Environmental Factors: Temperature and humidity can affect the performance of underfill materials. Camalot machines can be calibrated to account for these environmental variables, ensuring consistent results regardless of conditions.

- Curing Times: Different underfill materials have unique curing profiles, which can affect production schedules. Speedline Camalot offers machines that can accommodate various curing times, allowing for flexibility in production planning.

Industry Trends and Future Directions

Growing Demand for Miniaturization

As consumer electronics continue to shrink in size, the demand for more compact and efficient packaging solutions is driving innovation in underfill technology. Manufacturers are increasingly seeking underfill solutions that can support smaller, more densely packed components without sacrificing performance.

Advances in Materials Science

Ongoing advancements in materials science are leading to the development of new underfill formulations that offer improved performance characteristics. Speedline Camalot is committed to staying at the forefront of these developments, ensuring that its dispensing solutions can accommodate the latest materials.

Integration of Automation

The integration of automation into manufacturing processes is a key trend across industries. Speedline Camalot machines are designed to support automated workflows, allowing manufacturers to streamline their operations and enhance efficiency.

Emphasis on Sustainability

With growing concerns about environmental impact, manufacturers are increasingly focused on sustainability. Speedline Camalot’s precision dispensing technology helps reduce material waste, contributing to more sustainable manufacturing practices.

Increasing Use of IoT and Smart Manufacturing

The rise of the Internet of Things (IoT) and smart manufacturing technologies is transforming the electronics industry. Speedline Camalot machines are being equipped with smart features that enable real-time monitoring, data collection, and analysis, further enhancing their capabilities.

Conclusion

Underfill technology plays a crucial role in ensuring the reliability and performance of modern electronic devices. Speedline Camalot’s dispense machines, particularly those featuring SmartStream® pump technology, are at the forefront of this critical process. With their precision, speed, and versatility, Camalot machines provide manufacturers with the tools they need to meet the growing demands of the electronics industry.

As technology continues to advance, Speedline Camalot is committed to innovation, ensuring that its solutions evolve alongside the needs of manufacturers. By leveraging the capabilities of Camalot dispense machines, manufacturers can achieve enhanced production efficiency, lower costs, and improved product quality, positioning themselves for success in an increasingly competitive market.

In the ever-evolving landscape of electronics manufacturing, the role of underfill technology and the capabilities of Speedline Camalot will remain pivotal in driving innovation and reliability, ensuring that the next generation of electronic devices meets the highest standards of performance and durability.

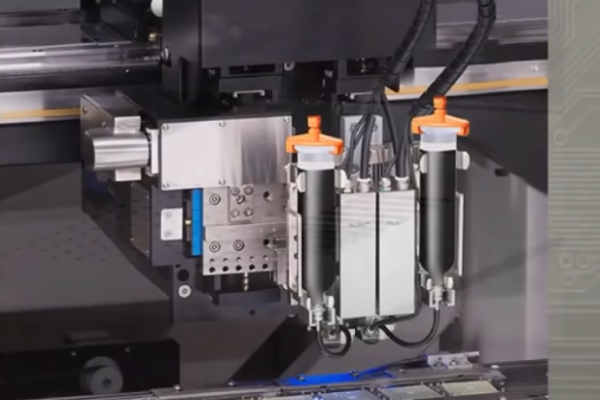

The Camalot Prodigy dispensing machine leverages cutting-edge technology to deliver faster processing, enhanced accuracy, and improved yields. Its advanced X-Y gantry system, paired with linear drive technology, ensures precise movement and positioning, while refined motion control optimizes the dispensing process. The sturdy frame design contributes to exceptional stability, minimizing vibrations that can affect performance. Together, these features make the Prodigy an ideal choice for manufacturers seeking reliable and efficient dispensing solutions, ultimately enhancing production quality and efficiency in various applications.