Introduction

As an expert in the field of Surface SMT, I understand that the efficiency and quality of printed circuit boards hinge significantly on the tools we use. One such critical component is the squeegee blade, especially when it comes to GKG printer machines. In this article, I will delve into the nuances of SMT squeegee blades, their compatibility with GKG printers, and how to select the best options to enhance production quality.

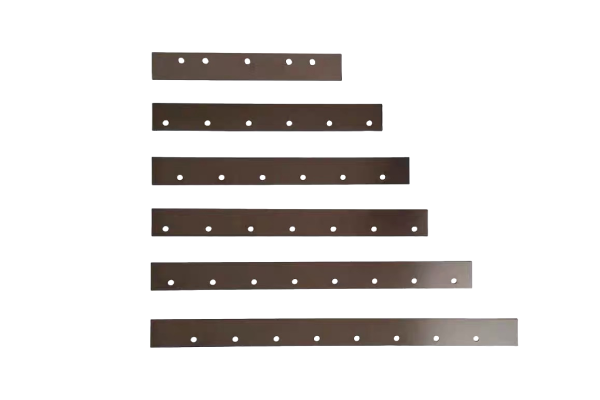

Understanding SMT Squeegee Blades

SMT squeegee blades play a pivotal role in the solder paste printing process. Their primary function is to apply solder paste evenly onto the PCB stencil, ensuring that each pad receives the correct amount of paste. For GKG printer machines, which are known for their precision and reliability, having the right squeegee blade is essential.The effectiveness of these blades directly influences print quality, production speed, and overall operational efficiency. A well-matched blade not only enhances paste transfer but also minimizes waste and reduces cleanup time.

Why Compatibility with GKG Printers Matters

Selecting smt squeegee blades that fit seamlessly with GKG printer models is crucial for maintaining high production quality. Each model has specific design parameters and operational requirements that dictate what type of blade is most effective. Using incompatible blades can lead to several issues, including inconsistent paste application, increased wear on machinery, and ultimately, compromised product quality.For instance, GKG printers like the G-Titan are equipped with advanced features such as Optimum-Paste Control and Quality-Print Control, which enhance printing accuracy 1. These features rely on precise blade performance; thus, choosing the right smt squeegee blade becomes a non-negotiable aspect of successful SMT production.

Essential Factors in Choosing SMT Squeegee Blades for GKG Printers

Ensuring Compatibility and Seamless Fit

To ensure optimal performance, it is vital to consider the specifications of GKG printers when selecting smt squeegee blades. Each model may have unique requirements regarding blade width, material composition, and hardness.

Overview of GKG Printer Specifications

GKG printers are designed with specific tolerances and operational parameters that affect smt squeegee blade compatibility. For example, the G-Titan has adjustable print gaps and supports various stencil frame sizes. Understanding these specifications allows users to choose blades that fit perfectly within these parameters.

Risks of Incompatible Smt Squeegee Blades

Using poorly fitting smt squeegee blades can result in several detrimental effects:

- Decreased Print Quality: Inconsistent pressure or improper alignment can lead to uneven solder paste application.

- Increased Equipment Wear: Mismatched blades can cause excessive friction or damage to the printer’s components.

- Higher Operational Costs: Frequent replacements due to wear or poor performance can inflate production costs significantly.

By selecting compatible smt squeegee blades designed for GKG printers, manufacturers can avoid these pitfalls and maintain a smooth production flow.

Finding Reliable Suppliers for GKG-Compatible Smt Squeegee Blades

Attributes of Reliable Suppliers

When sourcing smt squeegee blades for GKG printers, it’s essential to identify dependable suppliers. Here are key criteria to consider:

- Certification: Ensure that suppliers provide certified products that meet industry standards.

- Reputation: Look for suppliers with a proven track record in providing high-quality SMT components.

- After-Sales Support: Reliable suppliers should offer robust customer support and warranty options.

Comparing Options for Pricing, Quality, and Availability

Effective comparison among suppliers involves evaluating their offerings based on:

- Pricing: While lower prices are attractive, they should not come at the expense of quality.

- Material Quality: High-quality materials ensure better durability and performance.

- Inventory Levels: Suppliers with a consistent stock of compatible blades can minimize downtime during production.

- Suppliers: SMTCOMPONENTS CO., LIMITED

By analyzing these factors carefully, businesses can find suppliers that not only meet their budgetary constraints but also provide superior products.

Customer Feedback and Product Offerings

Why Customer Feedback Matters

Customer feedback is invaluable when assessing the performance of squeegee blades. Reviews from other users of GKG printers provide insights into durability, reliability, and overall satisfaction with specific products.

Product Offerings

GKG Asia offers a diverse range of products tailored to meet various customer needs:

- G-Tera: Advanced printing solutions focusing on efficiency.

- G-Titan: Recognized for its innovation, having won the Productronica Innovation Award in 2017.

- GL-Star: A product line likely designed for high-performance applications.

- D-Vis & DL-Vis: Multi-function dispensers that enhance operational capabilities.

- P-LED and P-Primo: These lines emphasize energy efficiency and cutting-edge technology.

This collective knowledge helps in making informed decisions about which products will best suit your production needs.

Key Challenges and Goals in SMT Production with GKG Squeegee Blades

Maximizing Equipment Efficiency

One of my primary goals as an SMT expert is maximizing equipment efficiency. High-quality squeegee blades prevent frequent production stops due to wear or poor performance. By investing in durable blades designed for GKG printers, manufacturers can achieve smoother operations and higher output rates.

Best Practices for Extending Blade Life

To maximize the lifespan of squeegee blades:

- Regular Maintenance: Implement a routine maintenance schedule to clean and inspect blades.

- Proper Storage: Store blades in a controlled environment to prevent degradation.

- Use Appropriate Pressure: Adjust printing pressure according to the specific requirements of each job.

These practices not only extend blade life but also contribute to consistent print quality over time.

Achieving Consistent Print Quality

Consistency in solder paste application is vital for producing reliable electronic components. High-quality smt squeegee blades contribute significantly to this consistency by ensuring precise application across all pads on a PCB.

Choosing Blades That Support Print Quality

When selecting squeegee blades for GKG printers, consider features such as:

- Material Composition: Different materials offer varying levels of flexibility and durability.

- Hardness Levels: The right hardness ensures optimal paste transfer without damaging stencils or PCBs.

By focusing on these attributes, manufacturers can enhance their printing processes significantly.

Balancing Cost-Effectiveness with Quality

Finding value in quality smt squeegee blades involves balancing upfront costs with long-term benefits. While cheaper options may seem appealing initially, they often lead to higher replacement rates and increased downtime.

Calculating Long-Term Savings

Investing in high-quality squeegee blades can yield significant cost savings over time. For example:

- Reduced Replacement Frequency: Durable blades last longer, minimizing purchase frequency.

- Improved Production Efficiency: Consistent print quality reduces rework costs associated with defective boards.

By calculating these potential savings against initial investments, businesses can make more informed purchasing decisions that benefit their bottom line.

Conclusion

Summary of Best Practices for GKG-Compatible Smt Squeegee Blades

In conclusion, selecting the right SMT squeegee blades for GKG printer machines involves several critical factors:

- Ensuring compatibility with specific printer models.

- Prioritizing quality from reliable suppliers.

- Leveraging customer feedback for informed choices.

- Implementing best practices for maintenance and usage.

Final Recommendations for Optimal Production

As you navigate your options for squeegee blades compatible with GKG printers, remember that investing in high-quality products will pay dividends in efficiency, print quality, and overall operational success. By following these guidelines, you can support efficient, high-quality, and cost-effective SMT production that meets the demands of today’s competitive electronics market.