Introduction

As someone deeply immersed in the world of surface mount technology (SMT), I can confidently say that SMT squeegee blades are among the most critical components in the solder paste printing process. These tools may seem simple, but they play a vital role in ensuring high-quality prints on printed circuit boards (PCBs). In this guide, I will share my insights on various types of SMT squeegee blades, their materials, performance comparisons across different printer brands in the industry.

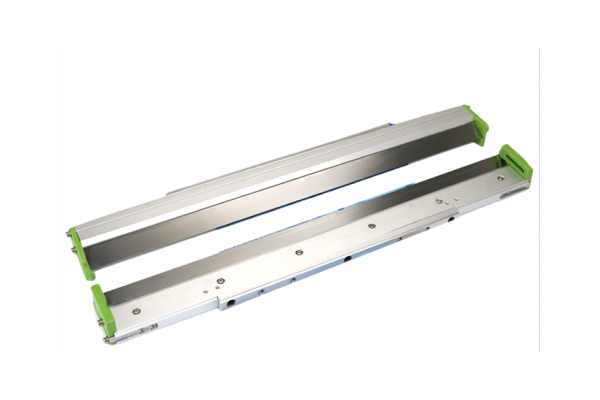

What are SMT Squeegee Blades?

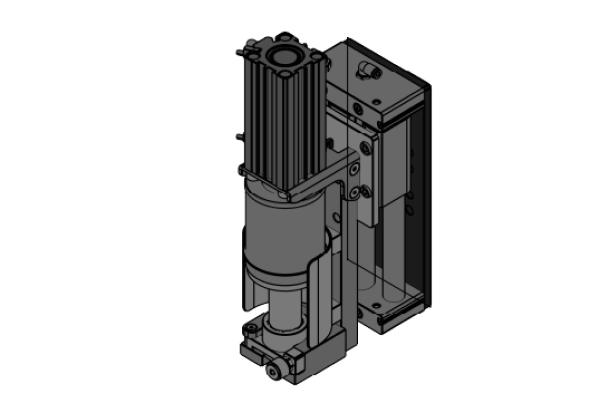

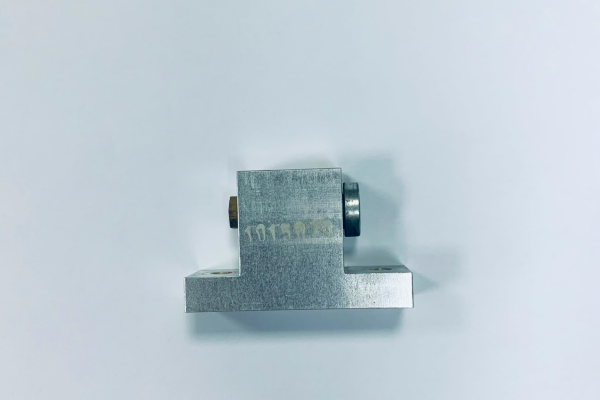

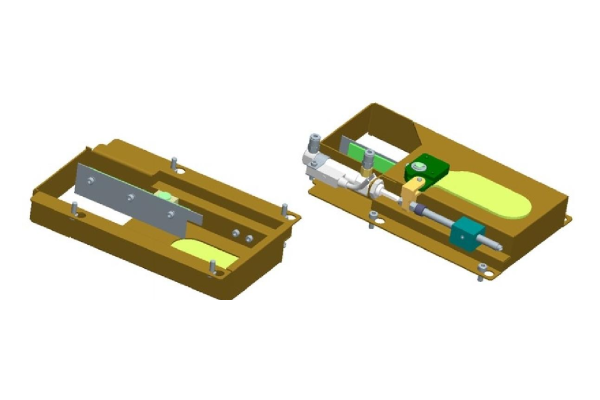

SMT squeegee blades are specialized tools designed to apply solder paste onto PCBs during manufacturing. They glide over stencils, pushing solder paste through apertures to create precise deposits on the board. From my experience, the effectiveness of this process hinges on the characteristics of the squeegee blades, including their material, design, and maintenance.

Importance of Squeegee Blades in SMT Applications

The significance of SMT squeegee blades cannot be overstated. I’ve seen firsthand how they directly influence print quality, which ultimately affects the reliability and performance of electronic devices. Here are a few reasons why choosing the right squeegee blade is crucial:

- Optimal Paste Transfer: A well-functioning blade ensures consistent and accurate paste application.

- Reduced Defects: High-quality blades minimize issues such as smearing or insufficient paste deposition.

- Cost Efficiency: Durable blades reduce replacement frequency and associated costs, which is something every manufacturer appreciates.

Types of SMT Printers and Their Squeegee Blades

Different types of SMT printers utilize various squeegee blade designs tailored to their specific requirements. Based on my observations and experiences, I will explore several prominent printer brands and their respective SMT squeegee blade options.

MPM Printer Squeegee Blades

Materials Used

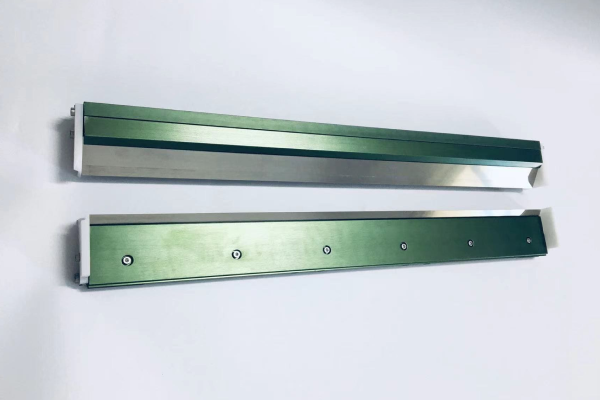

In my work with MPM printers 1, I’ve found that they typically use polyurethane and metal squeegee blades. Polyurethane blades are favored for their flexibility and ability to conform to stencil surfaces, while metal blades offer durability under high pressure.

Performance Comparison

MPM squeegee blades excel in applications requiring precision and adaptability. The polyurethane options are ideal for low-abrasion tasks, while metal variants perform exceptionally well under high-pressure conditions.

DEK Printer Squeegee Blades

Materials Used

DEK printers often utilize high-quality materials such as stainless steel and specialized polymers for their squeegees 2. I appreciate stainless steel for its durability, while polymers provide excellent flexibility.

Performance Comparison

From my experience, DEK’s stainless steel blades are known for their longevity and consistent performance, particularly in fine-pitch applications. The polymer options offer a softer touch for delicate components, making them versatile.

GKG Printer Squeegee Blades

Materials Used

When working with GKG printers 3, I’ve noticed that they primarily use polyurethane blades due to their excellent wear resistance and adaptability to various stencil designs.

Performance Comparison

GKG squeegees are designed for high-speed printing applications. They provide reliable paste deposition without compromising quality. Their flexibility allows for effective paste transfer even in challenging geometries.

Ekra Printer Squeegee Blades

Materials Used

Ekra printers feature a range of squeegee materials, including metal and advanced composites that enhance performance under varying conditions 4.

Performance Comparison

I find that Ekra’s squeegees are noted for their precision and ability to maintain print quality over extended runs. This makes them suitable for high-volume production environments where consistency is key.

ESE Printer Squeegee Blades

Materials Used

ESE uses both metal and polyurethane materials for their squeegees, catering to different printing needs based on application demands 5.

Performance Comparison

In my experience with ESE blades, they strike a balance between durability and flexibility. This ensures effective paste transfer across a variety of PCB designs without sacrificing quality.

MINAMI Printer Squeegee Blades

Materials Used

MINAMI printers employ high-grade stainless steel for their squeegees. I’ve found this material ensures robust performance in demanding applications.

Performance Comparison

MINAMI’s stainless steel blades provide exceptional stability and precision in paste application. This is particularly beneficial when working with intricate PCB layouts that require meticulous attention to detail.

HITACHI Printer Squeegee Blades

Materials Used

HITACHI utilizes a combination of polyurethane and metal materials tailored to specific printing requirements.

Performance Comparison

From what I’ve observed, HITACHI’s squeegees are designed to optimize print speed while maintaining high-quality paste deposits. This versatility makes them suitable for various production settings.

INOTIS Printer Squeegee Blades

Materials Used

INOTIS printers feature specialized composite materials that enhance blade performance under different operational conditions.

Performance Comparison

In my work with INOTIS squeegees, I’ve found them to excel in providing consistent print quality with minimal wear over time. They are suitable for both low- and high-volume production runs.

DESEN Printer Squeegee Blades

Materials Used

DESEN offers a variety of blade materials including advanced polymers designed for specific solder paste types 3.

Performance Comparison

I appreciate DESEN’s blades for their adaptability to various solder pastes. They ensure effective transfer even with challenging formulations, which is crucial in today’s diverse manufacturing environments.

Comparison of Squeegee Blades Across Different Printers

When comparing squeegee blades across different printer brands, several performance metrics come into play. Based on my observations, here’s a summary:

| Printer Brand | Material Types | Print Quality | Durability | Cost-Effectiveness |

|---|---|---|---|---|

| MPM | Polyurethane, Metal | High | Moderate | Moderate |

| DEK | Stainless Steel, Polymers | Very High | High | Moderate |

| GKG | Polyurethane | High | Moderate | High |

| Ekra | Metal, Composites | High | High | Moderate |

| ESE | Metal, Polyurethane | High | Moderate | High |

| MINAMI | Stainless Steel | Very High | High | Moderate |

| HITACHI | Polyurethane, Metal | High | Moderate | Moderate |

| INOTIS | Composite | High | High | Moderate |

| DESEN | Advanced Polymers | Moderate | Moderate | High |

Reliable Suppliers for SMT Squeegee Blades

Finding reliable suppliers is crucial for maintaining a steady supply of quality squeegee blades. Here’s a SMT squeegee blades reputable suppliers :

SMTCOMPONENTS CO., LIMITED: Known for OEM-compatible products that meet high standards.

Email Address: will@smtcomponents.com

Conclusion

In conclusion, choosing the right SMT squeegee blade is crucial for achieving optimal results in solder paste printing. Throughout my career in this field, I have witnessed how material composition and design features significantly impact print quality, durability, and cost-effectiveness.

When selecting a supplier, I encourage you to consider factors such as product reliability, customer service, and technical support. By understanding the nuances of different printer brands and their corresponding squeegees, you can make informed decisions that enhance your PCB assembly processes.

For anyone involved in SMT applications—whether you’re an engineer or a technician—investing time in selecting the appropriate SMT Squeegee Blades will yield long-term benefits in print quality and operational efficiency. Your choice can significantly influence not just your production output but also the overall success of your electronic manufacturing endeavors.