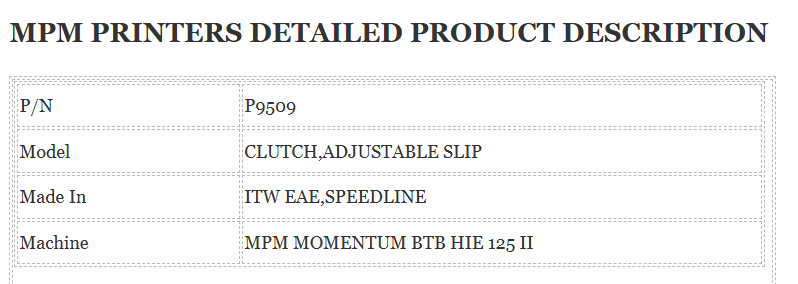

Mpm Printer P9509 CLUTCH High Quality ITW EAE Speedline

Supply the MPM Printer P9509 Clutch, a high-quality adjustable slip clutch designed for ITW EAE Speedline SMT printers. Perfect for precision and durability.

smt printing machine P9509 Clutch is a high-quality, adjustable slip clutch (8mm) designed as a reliable SMT spare part for ITW EAE Speedline systems.

It is compatible with advanced stencil printers like the Momentum II 100 and the Momentum BTB, which are configured back-to-back for enhanced efficiency in SMT production lines.

This clutch ensures precise performance and durability, making it an essential component for maintaining optimal functionality in modern MPM printers.