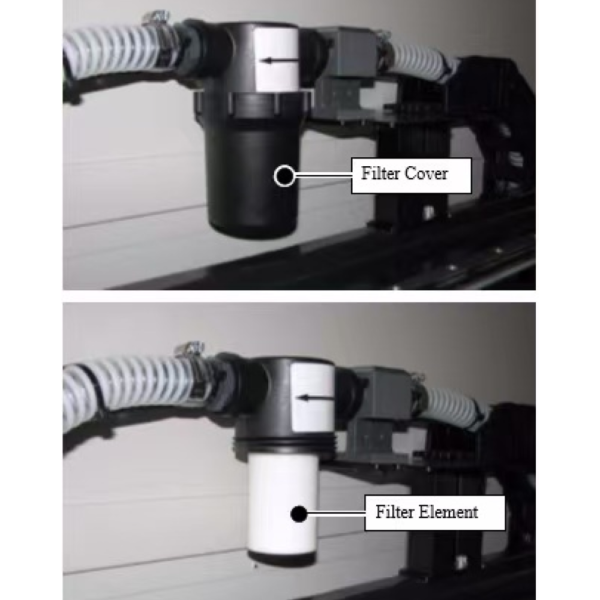

MPM Printer P10301, featuring the FILTER ELEMENT HDPE (P5092).

Mpm Momentum II is a fast, precise, and highly reliable printer designed for seamless performance. When configuring two printers back to back, the MPM Momentum ensures optimal efficiency and speed in all your printing operations.

Order your P10301: FILTER ELEMENT HDPE to enhance the performance of your ITW EAE Speedline Origin printer setup.

P10301 stands as an essential tool for achieving high-quality, consistent results in any production environment.