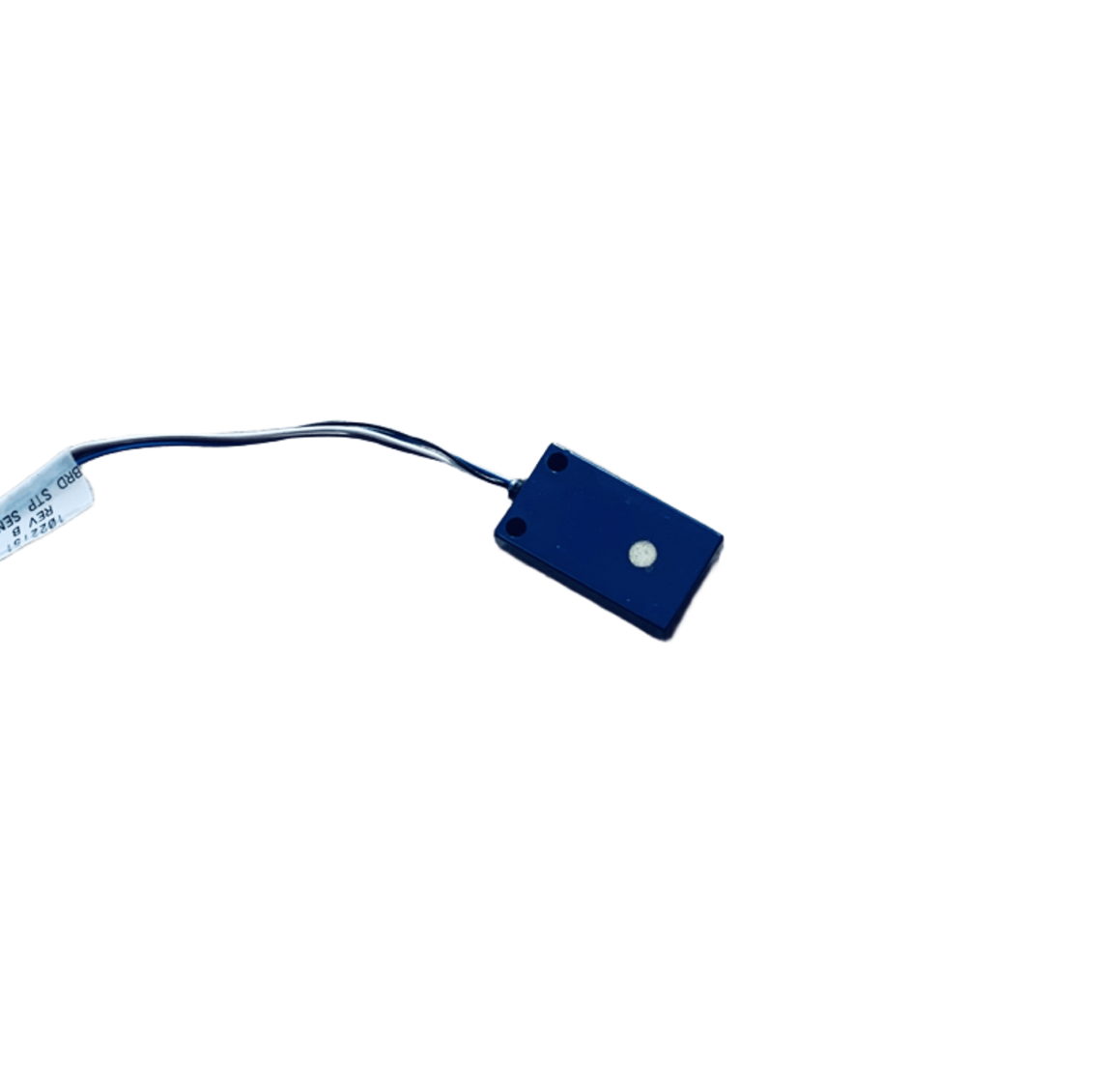

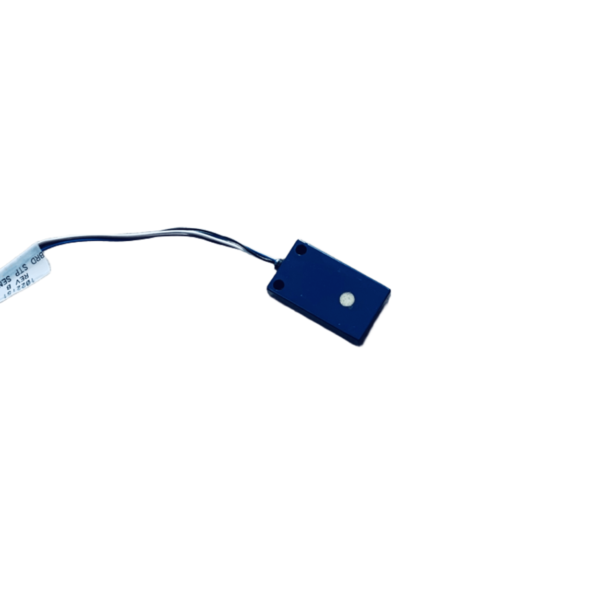

Mpm Printer 1022151 SENSOR ULTRASONIC Origin New ITW EAE

Mpm Printer 1022151 SENSOR,ULTRASONIC BOARD ,Edison printer is the industries’ most accurate printer,SPEEDLINE

|

| Stock | 1000 PCS |

| Quality | ORIGIN NEW COPY NEW |

| Price | GET A QUOTE |

| Deliver-Time | In Stock

OR |