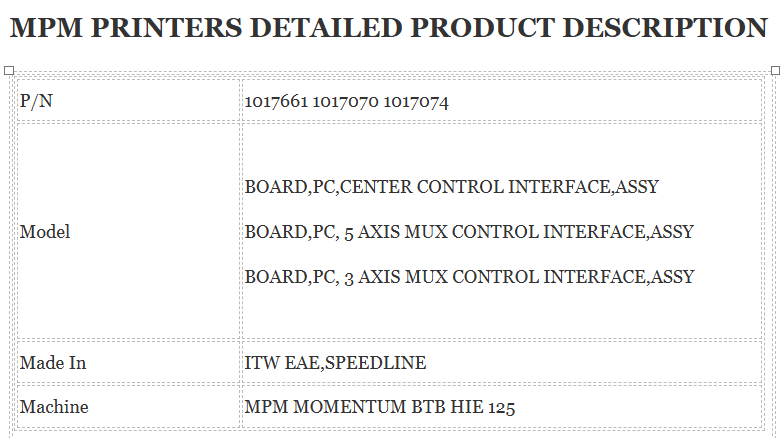

MPM Printer 1017661 board, which serves as a central control unit in MPM printers, has been replaced by the newer model 2009705. This update is particularly

relevant for the MPM Printer Momentum II, where the new board offers improved performance, reliability, and control functionality. The replacement enhances

the overall efficiency of the printer, ensuring better operation and maintenance. This change underscores MPM’s commitment to continuous improvement in the

performance and capabilities of their equipment.