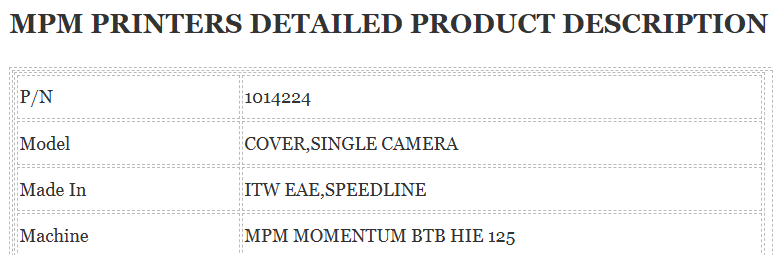

MPM Printer 1014224 Cover is a high-quality component from ITW EAE SPEEDLINE, designed to provide essential protection and support for the MPM Momentum Screen Printing machine.

This durable cover helps safeguard critical parts, ensuring the smooth operation of the printer, including the MPM squeegee system.

It plays a key role in maintaining the precision and reliability of the printing process.

The 1014224 cover is also compatible with other SMT printers, such as the ASM DEK models 191082 and 191088, enhancing the overall efficiency of solvent suction pumps and other related components.