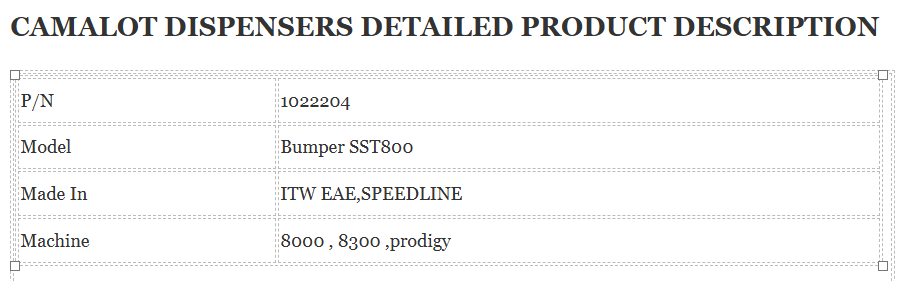

Camalot Dispensers 1022204

The proprietary design of Dynamic Dual Head (DDH) provides the only fast and fully accurate solution for dual head simultaneous dispensing. The DDH option uses a unique and patented mini XY drive system on a second Z-Axis to correct “real-time” and allow synchronous dispensing of both pumps regardless of part to part rotation. This technique guarantees increased productivity whilst maintaining yields through unsurpassed accuracy.

Key Features

- Independent, real time adjustment for both dispense pumps

- Dispense productivity increased by up to 100%

- No yield loss due to second head inaccuracy

- Compatible with all dispense pumps

- Automatic setup and calibration