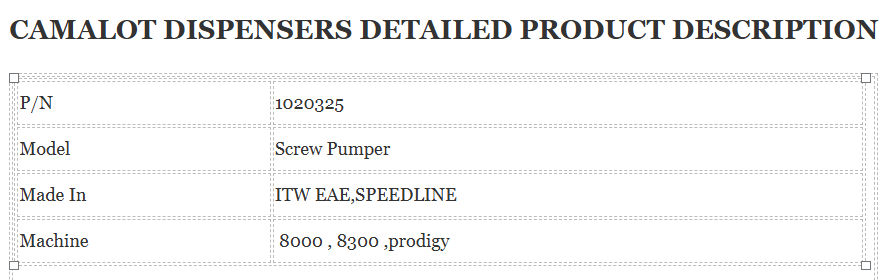

Camalot Dispenser utilizes the 1020325 Retaining Screw Pumper, an essential component for precise adhesive dispensing in various manufacturing processes.

Overview of the 1020325 Retaining Screw Pumper

1. Functionality

The Retaining Screw Pumper is designed to securely hold and regulate the flow of adhesive materials during dispensing. It ensures consistent pressure and volume, crucial for achieving uniform application.

2. Precision

This component enhances the accuracy of the dispensing process, allowing for intricate patterns and precise placements, particularly important in electronics assembly and other precision applications.