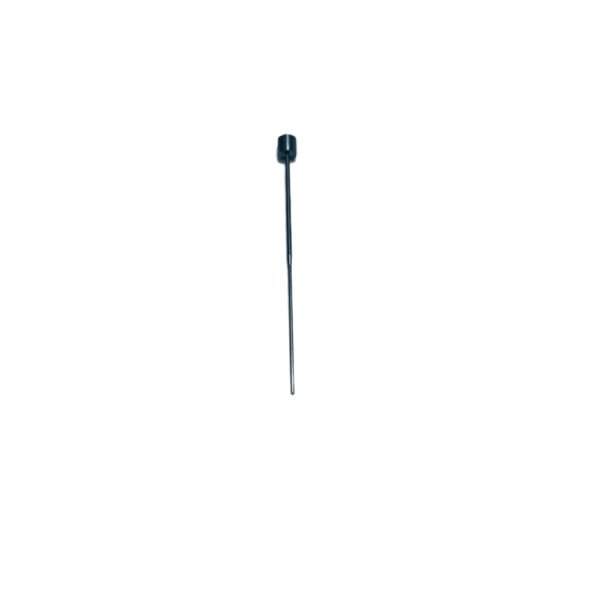

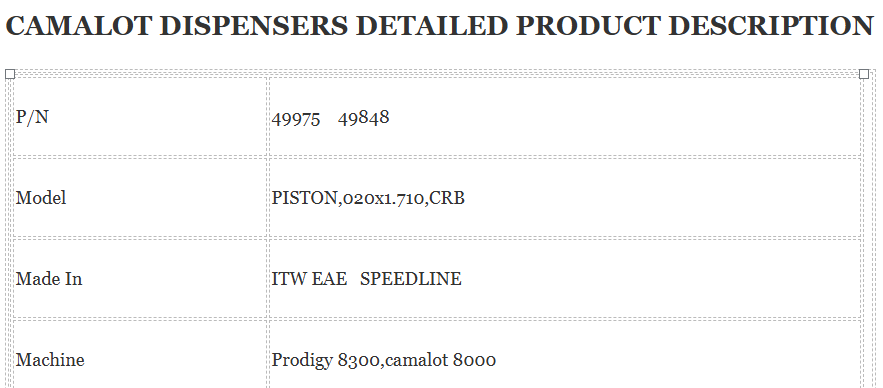

Camalot 49975 Piston 49848 Origin New Dispenser Speedline

Speedline , 020×1.710,CRB , Piston Camalot 49975 and 49848 are the key component for Camalot dispenser .

Camalot 49975 Piston and 49848 Origin New Dispenser from Speedline ITW EAE are innovative components designed for precision dispensing in various manufacturing applications. These components are essential in industries such as electronics, automotive, medical devices, and more, where accuracy and reliability in material application are critical.

Overview of Camalot Dispensers

Camalot dispensers are renowned for their ability to deliver a wide range of materials, including adhesives, sealants, and potting compounds. The integration of the 49975 Piston and 49848 Origin New Dispenser represents a significant advancement in the field of automated dispensing.

Key Features of the 49975 Piston

- Precision Control: The 49975 Piston is engineered for high precision, ensuring consistent material delivery. This feature is crucial in applications where the quantity and placement of materials directly affect the final product’s quality.

| Weight | 0.88 kg |

|---|---|

| Dimensions | 43 × 21 × 27 cm |