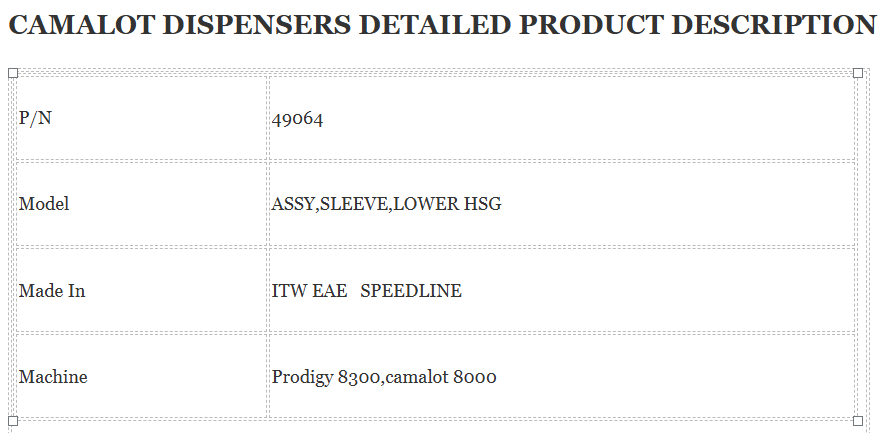

Camalot 49064 Sleeve ITW EAE Origin New Dispenser Speedline

ASSY,SLEEVE,LOWER HSG , Camalot 49064 is a component used in dispensing systems by Camalot, typically from Speedline ITW EAE

CIntroduction

Camalot 49064 Sleeve is a key component in the realm of adhesive dispensing systems, particularly under the ITW EAE brand. Known for its precision and reliability, this sleeve plays a pivotal role in enhancing the efficiency and quality of adhesive application processes across various industries. With a focus on innovation, the Camalot 49064 is designed to meet the diverse needs of modern manufacturing environments.

Overview of ITW EAE

ITW EAE (Illinois Tool Works Electronic Assembly Equipment) is renowned for its advanced manufacturing technologies. Specializing in equipment and systems for the electronics and assembly industries, ITW EAE offers a range of products that improve production efficiency and product quality. Their commitment to innovation is reflected in the design of their adhesive dispensing systems, including the Camalot series.

The Role of Dispensers in Manufacturing

Adhesive dispensers are critical in manufacturing settings where precision is paramount. They ensure that adhesives are applied consistently and accurately, minimizing waste and enhancing product integrity. The Camalot 49064 Sleeve is engineered to streamline this process, providing manufacturers with the tools they need to maintain high standards in production.