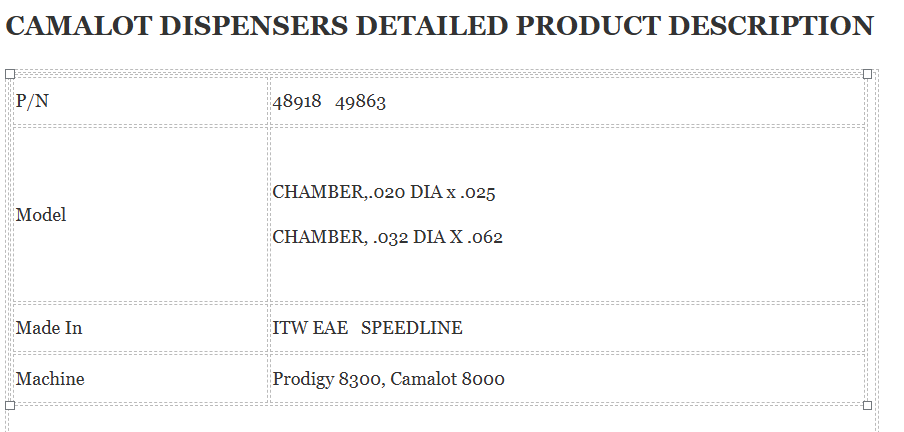

Overview of the Camalot 48918 Chamber and the Speedline ITW EAE Dispenser

The Camalot 48918 chamber, designed for use with the Speedline ITW EAE dispenser, represents a significant advancement in the realm of adhesive dispensing technology. As part of the broader landscape of automated dispensing solutions, this equipment is tailored to meet the needs of industries that require precision, efficiency, and reliability in their manufacturing processes.

Key Features

- Precision Engineering

The Camalot 48918 is built to deliver consistent, precise dispensing of adhesives and other materials. The chamber’s design minimizes waste and ensures uniform application, crucial for maintaining product quality. The precision of the dispenser is vital for applications in electronics, automotive, and medical device manufacturing, where even slight deviations can lead to defects. - Advanced Control Systems

The integration of sophisticated control systems allows operators to adjust the dispensing parameters easily. This includes flow rates, pressure settings, and timing. Such flexibility is essential for adapting to different materials and project requirements, ensuring that users can achieve optimal results for various applications. - User-Friendly Interface

The Speedline ITW EAE dispenser is equipped with an intuitive interface that simplifies operation. Users can quickly program and adjust settings, which reduces training time and minimizes the potential for errors during operation. This user-centric design enhances productivity and efficiency on the shop floor. - Material Compatibility

The Camalot 48918 is designed to work with a wide range of materials, including various adhesives, sealants, and potting compounds. This versatility makes it a valuable asset for manufacturers looking to streamline their processes without needing to invest in multiple dispensing systems.