Axxon Mycronic Dispenser MG18007401 Nozzle Insert Origin New

Axxon Mycronic Dispenser Nozzle Inserts—MG18007401, MG18005601 , MG18005701, MG18005801, MG18007301, and MG18007701

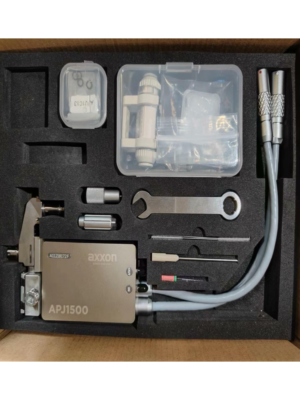

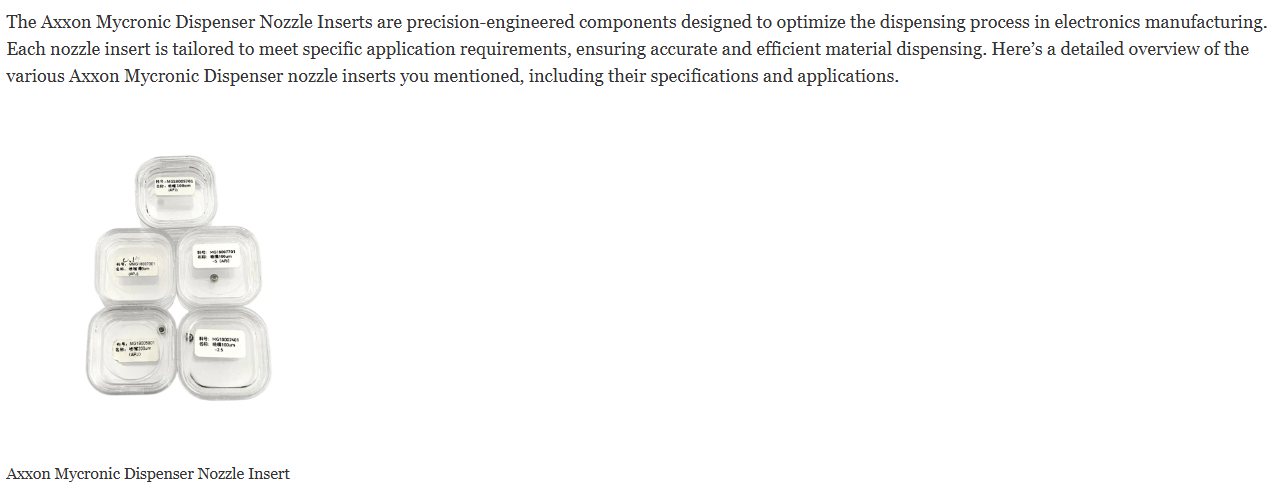

1. Overview of Axxon Mycronic Dispenser Nozzle Inserts

The nozzle inserts for the Axxon Mycronic Dispenser come in various sizes and specifications, allowing for versatility in material dispensing. These inserts are critical in controlling the flow rate, droplet size, and overall precision of the dispensing process. The following are the key specifications for each insert:

MG18007401

- Diameter: 100 µm

- Type: (-2.5)

- Flow Rate: 0.1 mm

This insert is ideal for applications requiring very fine dispensing. The smaller diameter allows for precise placement of materials, making it suitable for intricate assemblies and delicate components.

MG18005701

- Diameter: 100 µm

- Flow Rate: 0.1 mm

Similar to the MG18007401, this insert also features a 100 µm diameter but is designed for different material characteristics or dispensing conditions. It provides consistency and precision, ensuring that the correct amount of material is applied every time.

MG18005801

- Diameter: 200 µm

- Flow Rate: 0.2 mm

With a larger diameter, this nozzle insert is suited for applications that require a higher flow rate. It is ideal for dispensing thicker materials or for processes where faster application speeds are necessary.

MG18007301

- Diameter: 150 µm

- Flow Rate: 0.15 mm

This insert strikes a balance between the finer and wider options, making it versatile for various materials. It is particularly useful in situations where both precision and a moderate flow rate are required.

MG18007701

- Diameter: 100 µm

- Type: (-5)

- Flow Rate: 0.1 mm

Axxon Mycronic Dispenser Nozzle Inserts—MG18007401, MG18005701, MG18005801, MG18007301, and MG18007701—offer a range of options to meet the diverse needs of modern electronics manufacturing. By selecting the appropriate nozzle insert based on the specific requirements of the application, manufacturers can enhance their dispensing processes, improve efficiency, and maintain the quality of their products. As technology continues to advance, these precision components will play a vital role in the ever-evolving landscape of electronics production.