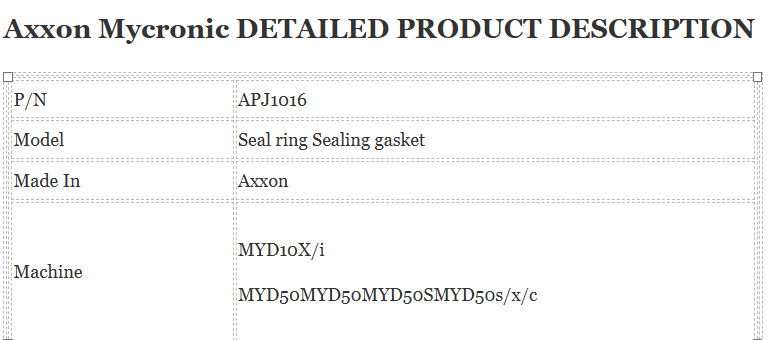

Axxon Dispenser APJ1016 Sealing Ring Origin New APJ1000S

APJ1000S Axxon Mycronic Dispenser APJ1016 Seal ring Sealing gasket ,For spare parts pricing, please contact our team.

Axxon Mycronic Dispenser APJ1016 Sealing Ring, often associated with the APJ1000S dispenser, is a critical component used in precision dispensing systems. These systems are integral to industries such as electronics manufacturing, automotive, and other fields that require precise application of adhesives, sealants, or other materials. Below, we’ll explore the purpose, specifications, and significance of the APJ1016 Sealing Ring in these high-precision applications.

Axxon Mycronic Dispenser APJ1016 Sealing Ring is a small yet vital component that plays a significant role in high-precision dispensing systems. Its design and material properties are carefully engineered to ensure that the dispensing process is reliable, consistent, and free from contamination. By maintaining a proper seal, the APJ1016 Sealing Ring helps manufacturers across various industries achieve the high level of precision required in modern production environments. Regular maintenance and timely replacement with original parts are essential to keep the dispenser performing at its best, ensuring high-quality outcomes and operational efficiency.