Axxon Dispenser V-8000S

The Axxon V-8000S dispenser is known for its precision, speed, and reliability in dispensing small volumes of fluids, including adhesives, solder paste, and other critical materials used in electronic component assembly. The system’s robust design allows for integration into automated production lines, providing consistent performance in high-throughput environments.

Key features of the Axxon V-8000S include:

- Precision Dispensing: Utilizes advanced valve technology to ensure accurate fluid delivery.

- High-Speed Operation: Optimized for rapid dispensing cycles, enhancing overall production efficiency.

- Versatile Material Compatibility: Handles a wide range of materials, from low-viscosity fluids to high-viscosity pastes.

- User-Friendly Interface: Offers an intuitive control system for easy setup and adjustments, minimizing downtime.

- Maintenance and Durability: Designed with ease of maintenance in mind, ensuring long-term reliability.

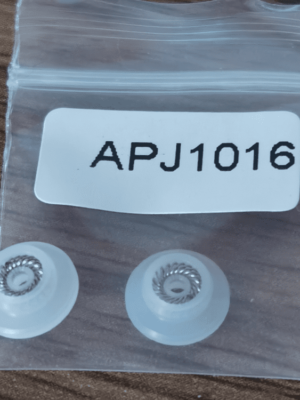

Axxon Dispenser V-8000S, paired with the Aguer Valve series, offers a comprehensive solution for precision fluid dispensing. Each valve in the series is tailored to handle specific viscosities and dispensing requirements, ensuring that the V-8000S can meet the diverse needs of modern manufacturing environments. This versatility makes the V-8000S and its associated valves a valuable tool in any production setting where precise material application is critical to product quality and performance.