Axxon Dispenser APJ1500 Jetting Valve APJ1000S Origin New

Axxon Dispenser APJ1500 and APJ1000S piezo jetting valve offers the capability to precisely dispense a wide range of materials.

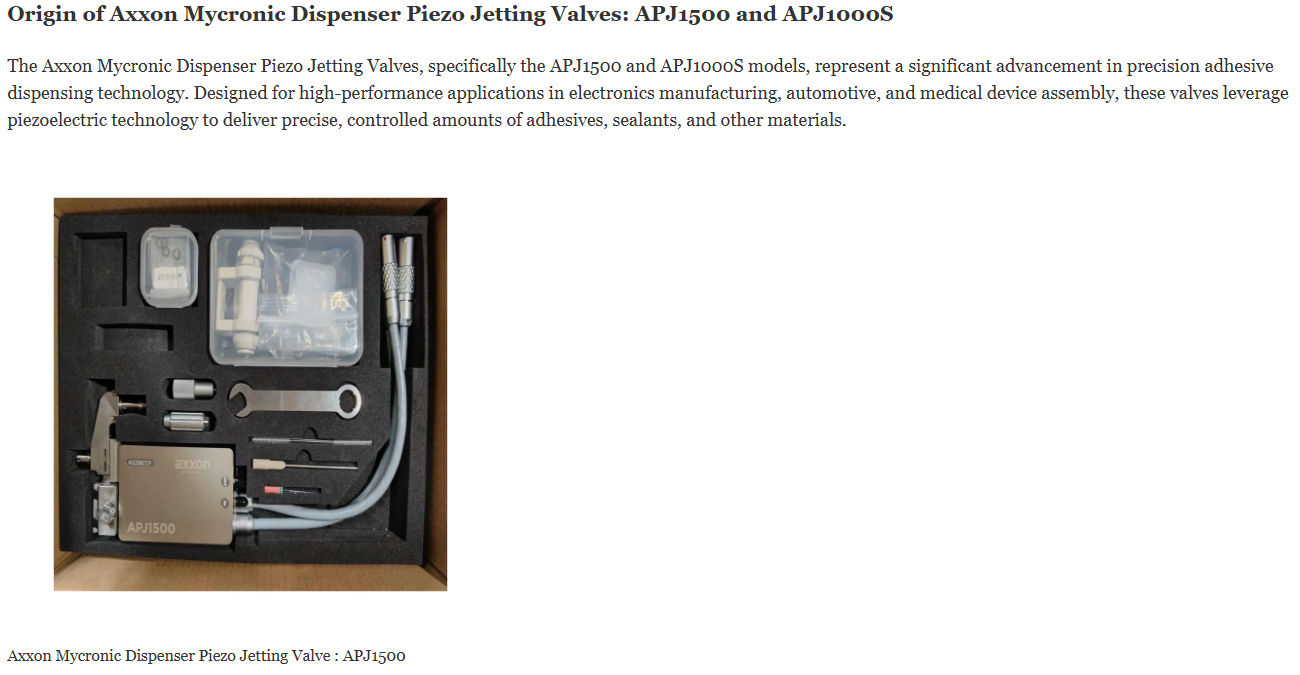

Axxon Dispenser APJ1500

The APJ1500 and APJ1000S utilize a piezoelectric actuation mechanism, which enables rapid response times and high-frequency jetting capabilities. This technology allows for the dispensing of small droplets with consistent volume and placement accuracy. The ability to adjust parameters such as drop size and jetting speed makes these dispensers highly versatile, accommodating a range of materials from low-viscosity liquids to more viscous adhesives.

One of the key features of these dispensers is their capability to handle a variety of viscosities, making them suitable for diverse applications. The APJ1500 is particularly noted for its higher throughput, while the APJ1000S is designed for more delicate applications requiring extreme precision. Both models excel in environments where reliability and performance are critical, reducing waste and improving production efficiency.

Axxon Dispenser APJ1500 and APJ1000S represent cutting-edge technology in the field of adhesive dispensing. Their precise control, versatility, and innovative features make them indispensable tools in various industries. As the demand for higher precision and efficiency in manufacturing continues to grow, these dispensers are poised to play a vital role in meeting those challenges, ensuring that Axxon remains at the forefront of dispensing technology.