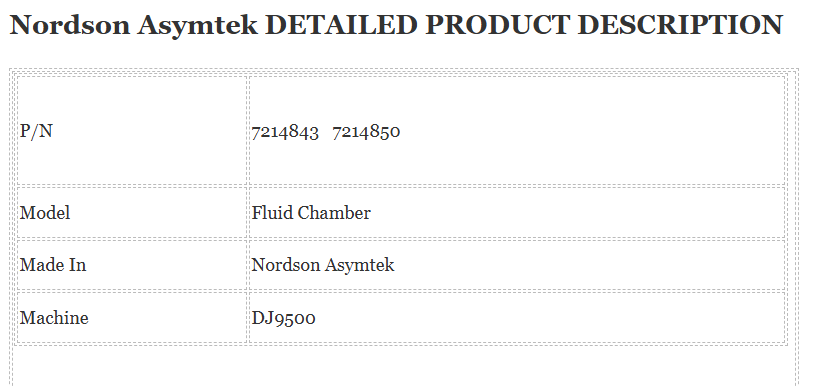

7214843 Fluid Chamber 7214850 Nordson Asymtek High quality

The 7214843 Fluid Chamber and 7214850 Nordson are specific part numbers associated with Asymtek equipment.

7214843 Fluid Chamber and 7214850 Nordson:

- Nozzles in Nordson Asymtek Equipment:

- Nozzles are crucial components in dispensing systems like those used in Nordson Asymtek machines. They control the flow and application of materials such as adhesives, sealants, or other fluids onto surfaces or into specific areas on a substrate.

- The specific design and dimensions of a nozzle determine the precision, flow rate, and pattern of the material being dispensed.

- In automated dispensing systems, such as those used in electronics manufacturing, these nozzles ensure that materials are applied consistently and accurately, which is essential for maintaining product quality.

Importance:

These nozzles are vital for achieving precise and consistent dispensing in various manufacturing processes, particularly in electronics where accuracy is crucial.

Introduction

Nordson Asymtek, a leading provider in dispensing technology, offers advanced solutions for fluid dispensing in various industrial applications. Among their products, the Fluid Chambers models 7214843 and 7214850 stand out for their high quality and performance. These components are integral to achieving precise fluid dispensing, a crucial aspect in electronics manufacturing, medical device assembly, and other high-tech industries.

Key Features

1. Precision Engineering

The Fluid Chambers 7214843 and 7214850 are engineered to meet the rigorous demands of precise fluid dispensing. They are designed to provide consistent and accurate control over the flow of fluids, ensuring that every application adheres to stringent quality standards. This precision is essential for applications where even minor deviations can lead to significant performance issues.

2. High-Quality Materials

Constructed from high-quality materials, these fluid chambers are built to endure the harsh conditions often found in industrial environments. The choice of materials ensures resistance to wear and tear, chemical corrosion, and temperature variations. This durability enhances the reliability and longevity of the fluid chambers, reducing the need for frequent replacements and maintenance.

3. Advanced Design

The design of the Fluid Chambers 7214843 and 7214850 incorporates advanced technology to optimize fluid flow and minimize waste. Features such as precise fluid metering and controlled dispensing are integral to the chambers’ design, making them suitable for applications requiring high accuracy and efficiency. The chambers are also designed for easy integration into existing systems, streamlining the setup and operational processes.

4. Versatility

These fluid chambers are versatile and can be used in a range of applications beyond electronics manufacturing. They are suitable for dispensing a variety of fluids, including adhesives, solder pastes, and coatings. This versatility makes them valuable assets in different production environments, from automotive to medical device manufacturing.

Applications

1. Electronics Manufacturing

In electronics manufacturing, the Fluid Chambers 7214843 and 7214850 are used for dispensing solder pastes and adhesives onto PCBs. Their precise fluid control ensures that components are securely bonded and that soldering processes are reliable, contributing to the overall quality and durability of electronic products.

2. Medical Device Assembly

For medical device assembly, these fluid chambers facilitate the precise application of adhesives and other critical fluids. The accuracy and reliability of these components are crucial in ensuring that medical devices function correctly and meet safety standards.

Conclusion

The Nordson Asymtek Fluid Chambers 7214843 and 7214850 represent the pinnacle of precision and quality in fluid dispensing technology. Their robust construction, advanced design, and versatility make them essential components for achieving high standards in various industrial applications. By ensuring accurate and reliable fluid dispensing, these fluid chambers contribute significantly to the efficiency and quality of the manufacturing processes they support.

| Weight | 0.88 kg |

|---|---|

| Dimensions | 43 × 21 × 27 cm |