MPM PRINTERS DETAILED PRODUCT DESCRIPTION

JAR PASTE DISPENSER

|

| Stock | 1000 PCS |

| Quality | ORIGIN NEW COPY NEW |

| Price | GET A QUOTE |

| Deliver-Time | In Stock

OR |

The MPM Printer sensors 2006345, 2006346, and 2006343 are integral to the superior performance of the MPM Momentum series printers. These sensors, designed by ITW EAE, provide the precision, reliability, and control necessary to achieve high-quality PCB printing. By ensuring accurate monitoring and real-time adjustments, they contribute to the efficiency and effectiveness of the SMT process, making them an indispensable component in modern electronics manufacturing. Investing in original, high-quality sensors ensures the long-term success and productivity of MPM printing systems

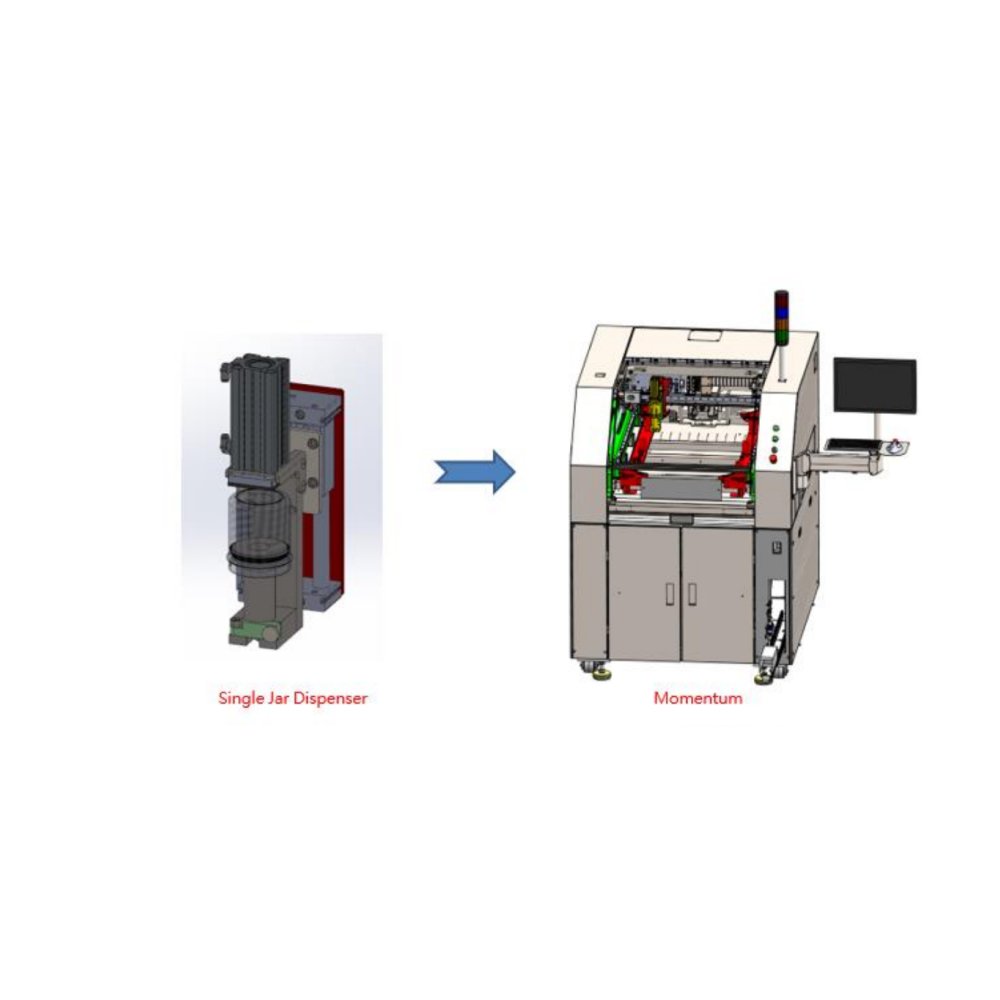

JAR PASTE DISPENSER

There are a few related changes to the Momentum and Momentum BTB platforms as well as the

introduction of the “Jar Paste Dispenser” feature.

The first of these is the introduction of the “Front Mounted Lateral Dual Jar or Single Jar” paste

dispenser, this feature is the same as conventional paste dispenser (Cartridge type). Second is the

dispensing feature called “Front Mounted Lateral Dual Jar” and “Front Mounted Lateral Single Jar”.

This kind of paste dispensing occurs only with the front jars mounted in the dispenser bracket

assembly which moves in the X-axis. Each dispenser jar (Dual or Single) is held in place by jar

paste holder arrangement.

The system is capable of dispensing only solder paste.

The Jar Paste Dispenser assembly mounts to the linear bearing on the front edge of the carriage the

same as the traditional paste dispenser. The major aspect of this is that this is front mounted which

provides for ease of serviceability.

The Jar Paste Dispenser also has the capability of being usable when the printer is configured with

conventional squeegee blades.

The Jar Paste Dispenser also is compatible with the Camalot Inside feature.

The Jar Paste Dispenser is not compatible with the Enclosed Flow Pump Head feature when

mounted.

THE MOMENTUM II 100 STENCIL PRINTER IS A HARD-WORKING

MPM printers are engineered with proven technology that was built on our successful legacy MPM stencil printer machines.

From MPM printer head technology to vision system development, today’s leading Momentum series of stencil printers are ready

to meet the most exacting manufacturing challenges.