The Ballscrew (Part Numbers: 2006133, 1014609, 1014606) is a critical component used in MPM Accela printers, ensuring smooth and precise movement for the printing process.

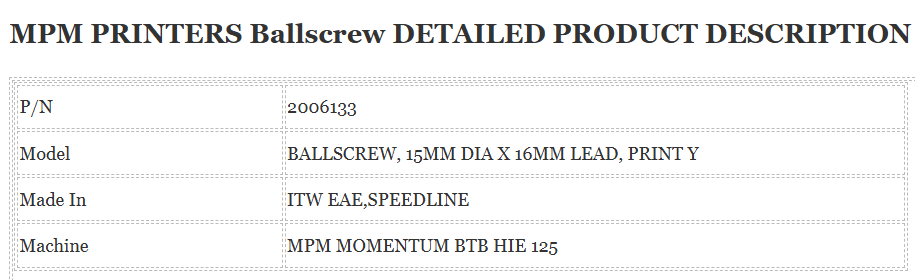

The 2006133 Ballscrew MPM Printer, part of the Momentum II PRINT Y series, is an original and new part, designed to maintain the high performance and reliability of your printer.

This essential part plays a key role in the accuracy and efficiency of MPM printers, making it indispensable for seamless operation.