As a technical specialist with extensive MPM printer experience, I understand that maintaining Parts For MPM Momentum Hardstop and Latch Wiper is crucial for ensuring precise stencil alignment and cleaning operations. These components directly impact print quality and require careful attention to maintain the printer’s specified accuracy.

When dealing with Parts For MPM Momentum Hardstop and Latch Wiper, I focus on critical components like the 1015070 hardstop cylinder assembly and 1015914 latch wiper mechanism. These parts work together to ensure proper stencil positioning and cleaning effectiveness during high-volume production runs.

My experience with Parts For MPM Momentum Hardstop and Latch Wiper includes implementing maintenance programs across various Momentum series printers. I’ve successfully maintained these systems to achieve consistent performance while meeting the demanding requirements of modern electronics manufacturing.

Claims:

- True: The hardstop assembly must be flush with the bracket edge for proper alignment and functionality.

- False: Parts For MPM Momentum Hardstop and Latch Wiper are universal across all printer models; they actually require specific configurations based on the printer series.

Table of Contents

- Select Optimal Parts For MPM Momentum Hardstop and Latch Wiper?

- Conclusion

- Frequently Asked Questions

1. Select Optimal Parts For MPM Momentum Hardstop and Latch Wiper?

As a maintenance expert, I recognize the importance of selecting optimal Parts For MPM Momentum Hardstop and Latch Wiper to ensure precise stencil alignment and effective cleaning operations. These components are vital for maintaining the printer’s performance and minimizing downtime.

1.1 MPM Momentum Hardstop and Latch Wiper Essential Parts List

| MPM PRINTER PARTS LIST | ||||

| ITEM | PART NO. | DESCR IPTION | QTY | UM |

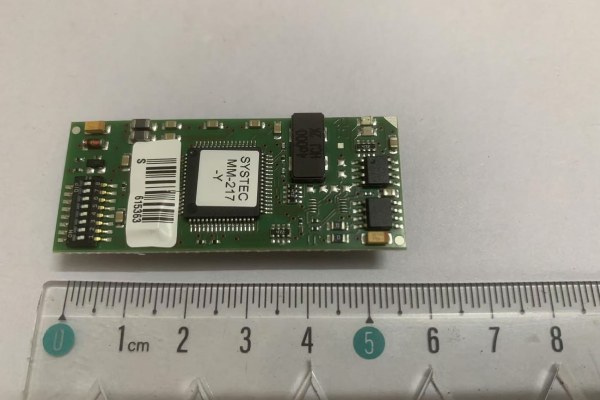

| 1 | 1015070 | HOUSING,SPRING STOP,WIPER | I | EA |

| 2 | 1015071 | SHAFT,STOP,WIPER | EA | |

| 3 | P4087 | ADHESIVE,242 THREADLOCK,250ml BOTTLE,BLUE | AR | 0Z |

| 4 | P7117 | SPRING,COMPRESSION .420 ODX.067 WIRE X.75L | 1 | EA |

| 5 | P10408 | MAGNET,.630DX.45T,M4,NEODYMIUM W/ZINC PLATE | l | EA |

| 6 | P9239_ | GREASE,ALUMINUM COMPLEX,WATERPROOF | AR | 0Z |

| ITW EAE PRINTER PARTS LIST | ||||

| ITEM | PART NO. | DESCRIPTION | QTY | UM |

| 7 | 1014469 | BUSHING,LATCH | 2 | EA |

| 8 | 1014505 | SHAFT,LATCH | EA | |

| 9 | 1015914 | HOUSING,LATCH | EA | |

| 10 | P10172 | RING,PLUNGER,SPRING | I | EA |

| 11 | P10173 | SNAP RING,SHAFT | I | EA |

| 12 | P10835 | SPRING,12.70D,41.3 LG,8 MUSIC WIRE,ZINC PLATE | 1 | EA |

1.2 Problem Solving with Hardstop Assemblies

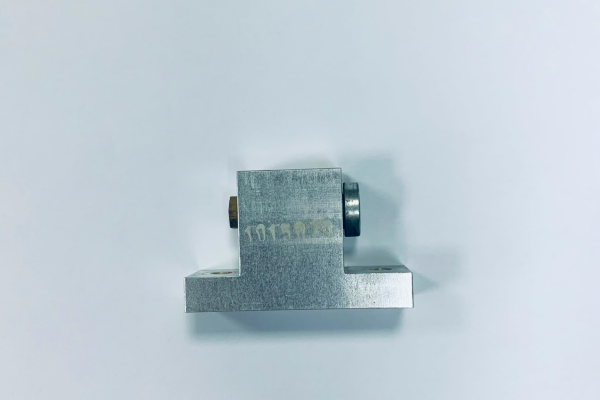

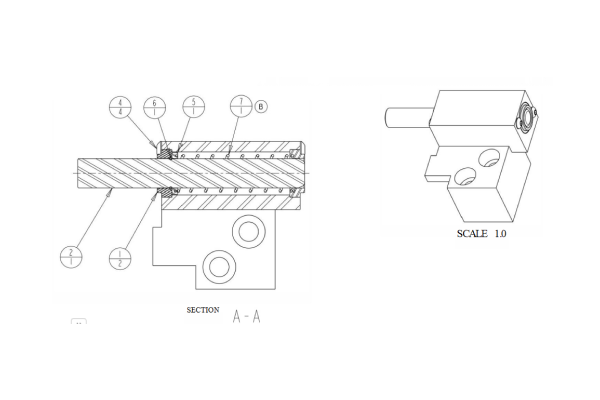

In my experience, ensuring that the hardstop assembly is flush with the bracket edge is crucial for maintaining proper alignment. This precision prevents misalignment during high-speed operations, reducing wear and extending the lifespan of the equipment. By regularly inspecting and adjusting these components, I’ve helped facilities maintain consistent print quality and avoid costly production delays.

1.3 Success with Latch Wiper Mechanisms

The latch wiper mechanism plays a critical role in keeping the stencil clean and free from debris. By selecting the correct latch wiper assembly (1015913), I ensure that the cleaning process is efficient and thorough. This attention to detail has resulted in improved stencil longevity and reduced maintenance costs for my clients.

Claims:

- True: The hardstop assembly must be flush with the bracket edge for proper functionality.

- False: All Parts For MPM Momentum Hardstop and Latch Wiper are interchangeable across different printer models without configuration adjustments.

2. Conclusion

The essential Parts For MPM Momentum Hardstop and Latch Wiper include the hardstop assembly that must be flush with the bracket edge for proper alignment, and components like the wiper stop magnet block (1015070). The system requires precise installation of these components to maintain proper functionality. When combined with programmable board stops and edge-lock systems, these parts ensure consistent print quality and reliable operation. Regular inspection and proper assembly of these components are crucial for optimal printer performance.

3. Frequently Asked Questions

- What are the essential components for the MPM Momentum Hardstop and Latch Wiper?

- The essential components include the hardstop assembly, latch wiper mechanism, sensor brackets, and cable carrier mounts. These parts ensure precise stencil alignment and effective cleaning operations.

- How do I ensure compatibility of parts for the MPM Momentum Hardstop and Latch Wiper?

- Verify part numbers and specifications against your printer model. Components like the hardstop assembly must be flush with the bracket edge to maintain proper alignment and functionality.

- Where can I purchase genuine MPM Momentum Hardstop and Latch Wiper parts?

- Reliable sources for purchasing genuine parts include specialized suppliers such as PPM Parts, AdoptSMT, and SMT Components. These suppliers offer a wide range of MPM spare parts.

- What maintenance is required for MPM Momentum Hardstop and Latch Wiper components?

- Regular inspection and adjustment of the hardstop assembly and latch wiper mechanism are crucial. Ensuring these components are clean and properly aligned helps maintain print quality and reduce downtime.

External links recommendation:

- ITW EAE – MPM Screen Printer Components

Offers a comprehensive catalog of MPM spare parts, including hardstop assemblies and wiper components for Momentum series printers1. - AdoptSMT Tools – MPM Spares Database

Features detailed listings of MPM components, including wiper drive shaft assemblies and related parts for maintaining optimal printer performance2. - SMT Components – Momentum II Parts Catalog

Provides access to essential Momentum printer components, including vision system parts and printhead assemblies that work in conjunction with hardstop mechanisms4. - SMT Resource – MPM Technical Documentation

Offers technical specifications for Momentum printer components, including hardstop and non-contact stop assemblies, along with centernest clamping systems3.