As a dispensing technology specialist, I’ve witnessed how NuJet Pneumatic Dispenser Pump Technology has revolutionized precision dispensing through its innovative needle-free design and exceptional speed capabilities.

NuJet Pneumatic Dispenser Pump Technology delivers superior dispensing performance through its state-of-the-art pneumatic actuator operating at up to 300Hz frequency, compact design for minimal mass, and exceptional control for consistent process results.

The evolution of NuJet Pneumatic Dispenser Pump Technology represents a significant advancement in dispensing systems, offering manufacturers a solution that combines ease of use with reduced cost of ownership while maintaining the highest levels of accuracy and repeatability.

Claims:

- True: NuJet’s compact design and high-frequency pneumatic actuator allow for fast dispensing and exceptional control. NuJet uses a contact jetting technique instead of a needle.

- False: NuJet requires frequent actuator replacements; in fact, its compact design minimizes wear and maintenance requirements.

Table of Contents

- How Does NuJet Pneumatic Dispenser Pump Technology Achieve Superior Speed?

- What Makes NuJet Pneumatic Dispenser Pump Technology Cost-Effective?

- Why Is NuJet Pneumatic Dispenser Pump Technology Industry-Leading?

How Does NuJet Pneumatic Dispenser Pump Technology Achieve Superior Speed?

As a dispensing systems expert, I can attest that NuJet Pneumatic Dispenser Pump Technology represents a breakthrough in high-speed dispensing through its innovative needle-free design and state-of-the-art pneumatic actuation system.

Speed Performance

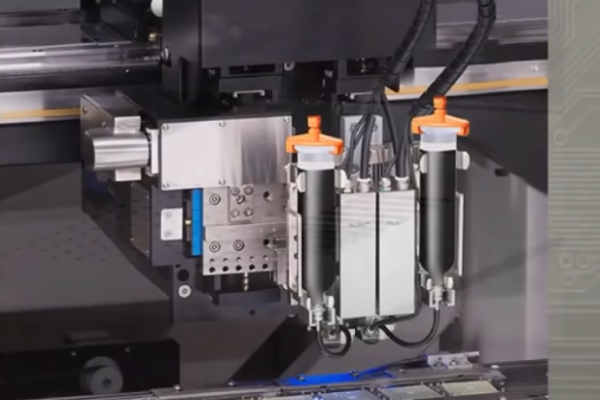

NuJet Pneumatic Dispenser Pump Technology achieves superior speed through its pneumatic actuator operating at frequencies up to 300Hz, while its compact design minimizes mass for extremely fast dispensing and exceptional control.

Advanced Capabilities

NuJet Pneumatic Dispenser Pump Technology utilizes a sophisticated contact jetting technique to displace dispensing material. The combination of pneumatic actuation and closed-loop software control ensures consistent process results while maintaining exceptional accuracy and repeatability, even at high operating speeds.

The innovative design philosophy behind NuJet Pneumatic Dispenser Pump Technology prioritizes both performance and practicality. By eliminating the traditional needle-based approach, the system reduces maintenance requirements and simplifies material flow control, while its compact form factor enables rapid acceleration and deceleration during dispensing operations.

Claims:

- True: NuJet pneumatic dispenser pump technology achieves superior speed by utilizing a high-performance pneumatic actuator that can generate a very high operating frequency, often reaching up to 300Hz, allowing for rapid fluid dispensing cycles, making it one of the fastest dispensing systems available on the market; this is typically combined with a sophisticated motion control system to ensure precision alongside speed.

- False: NuJet requires complex calibration procedures; in fact, its closed-loop software control enables consistent performance with minimal setup requirements.

What Makes NuJet Pneumatic Dispenser Pump Technology Cost-Effective?

As a dispensing systems specialist, I can attest that NuJet Pneumatic Dispenser Pump Technology revolutionizes cost-effectiveness through its innovative needle-free design and minimal maintenance requirements.

Key Cost-Saving Features

- Eliminates needle replacement costs and maintenance

- Compact design minimizes wear and part replacements

- Operating frequency up to 300Hz increases throughput

- Closed-loop software control reduces material waste

- Quick changeover capabilities for different materials

- Reduced downtime due to simplified maintenance

Operational Excellence

NuJet Pneumatic Dispenser Pump Technology achieves significant cost savings through its state-of-the-art pneumatic actuator design. By eliminating the need for needles and incorporating closed-loop software control, the system maintains exceptional accuracy while reducing consumable costs and maintenance requirements.

The compact design of NuJet Pneumatic Dispenser Pump Technology minimizes mass and enables extremely fast dispensing with exceptional control. This efficiency translates directly to increased productivity, as the system can maintain consistent process results while operating at frequencies up to 300Hz.

The versatility of NuJet Pneumatic Dispenser Pump Technology further enhances its cost-effectiveness through compatibility with various materials and applications. The system’s quick-change capability and minimal maintenance requirements, needed only on a weekly basis, ensure more uptime for higher productivity while reducing operational costs.

Claims:

- True: NuJet eliminates use of a needle and incorporates a contact jetting technique to displace the dispense material. Controlling the piston with a pneumatic actuator and closed-loop software achieves a high degree of accuracy and repeatability for consistent process results.

- False: NuJet requires daily calibration for accurate dispensing; in reality, it features auto-tune capability for automatic calibration.

Why Is NuJet Pneumatic Dispenser Pump Technology Industry-Leading?

As a dispensing technology expert, I can confirm that NuJet Pneumatic Dispenser Pump Technology stands as the industry benchmark through its revolutionary needle-free design and exceptional process control capabilities.

Performance Metrics

| Feature | Specification |

|---|---|

| Operating Frequency | Up to 300 Hz |

| Dispensing Method | Contact Jetting |

| Control System | Closed-loop Software |

| Design | Compact, Minimal Mass |

| Maintenance | Reduced Requirements |

Advanced Capabilities

NuJet Pneumatic Dispenser Pump Technology revolutionizes dispensing through its state-of-the-art pneumatic actuator system that eliminates the need for traditional needles. The compact design minimizes mass while enabling extremely fast dispensing rates, achieving operating frequencies up to 300 Hz with exceptional control precision.

The integration of closed-loop software control in NuJet Pneumatic Dispenser Pump Technology ensures consistent process results and high repeatability. This innovative approach simplifies maintenance requirements while reducing the total cost of ownership, making it an ideal solution for high-volume manufacturing environments that demand both speed and precision.

Claims:

- True: NuJet pneumatic dispenser pump technology is considered industry-leading due to its exceptional speed, high accuracy, compact design, and ability to deliver consistent, repeatable results through a contact jetting technique, all achieved with a closed-loop control system that eliminates the need for a needle, making it ideal for fast, precise dispensing in applications like electronic assembly where high-speed, accurate dot placement is crucial.

- False: NuJet requires specialized materials for operation; in fact, it’s designed to work with standard dispensing materials while maintaining exceptional control.

Conclusion

NuJet Pneumatic Dispenser Pump Technology represents a breakthrough in dispensing innovation, combining exceptional speed with precision control. Its needle-free design and state-of-the-art pneumatic actuator achieve frequencies up to 300Hz while maintaining consistent accuracy The compact, low-mass design enables extremely fast dispensing while reducing maintenance requirements. With its closed-loop software control and ability to be pitched down to 28mm for dual-head applications, NuJet delivers superior process results while lowering the total cost of ownership. This technology has proven particularly valuable for high-volume manufacturing environments where speed, precision, and reliability are paramount.

Frequently Asked Questions

1. What makes NuJet Pneumatic Dispenser Pump Technology unique?

NuJet eliminates the need for needles by using a pneumatic actuator to control a contact jetting mechanism, achieving dispensing frequencies of up to 300 Hz with exceptional accuracy and repeatability67.

2. How does NuJet improve production efficiency?

Its compact, lightweight design minimizes mass, enabling faster dispensing speeds and reducing cycle times, making it ideal for high-volume manufacturing environments67.

3. Is NuJet compatible with standard dispensing materials?

Yes, NuJet is designed to handle a wide range of materials without requiring specialized formulations, offering flexibility across various applications78.

4. Does NuJet require frequent maintenance?

No, the system’s robust pneumatic actuator and compact design minimize wear and maintenance requirements, reducing downtime and cost of ownership67.

- ITW EAE Overview – A detailed PDF highlighting NuJet’s compact, fast, and flexible design, along with its integration into advanced dispensing systems like Camalot Prodigy1.

- Jetting Technology to Increase Productivity – An article explaining how NuJet achieves high-speed dispensing with a pneumatic actuator operating at up to 300 Hz while maintaining exceptional accuracy and repeatability2.

- Camalot Prodigy Video Overview – A YouTube video showcasing NuJet’s needle-free design, compact architecture, and exceptional control for high-speed dispensing applications4.

- Prodigy Dual Lane Dispenser – A comprehensive feature breakdown of Camalot’s Prodigy platform, including NuJet’s integration for increased throughput and precision5.