As a dispensing systems expert, I can attest that the Needle Cleaner and Detector for Camalot Prodigy is an essential feature that enhances precision and reliability in high-volume dispensing applications. This technology ensures that needles remain clean and properly aligned, reducing downtime and maintaining consistent performance.

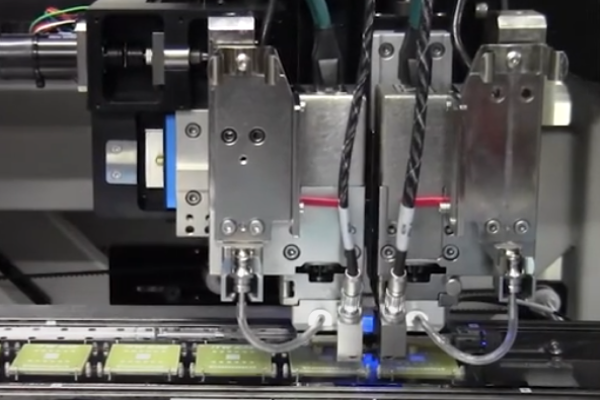

The Needle Cleaner and Detector for Camalot Prodigy uses a vacuum-based cleaning station to maintain needle cleanliness and a detector to verify needle straightness and presence, compatible with 12–32 gauge needles. This system minimizes maintenance interruptions and ensures precise material deposition.

The integration of the Needle Cleaner and Detector for Camalot Prodigy reflects ITW EAE’s commitment to providing advanced solutions that enhance operational efficiency. By automating needle maintenance, this feature reduces manual intervention, allowing operators to focus on optimizing production processes.

Claims:

- True: A vacuum-based cleaning station ensures cleanliness of needle/nozzle. A detector is used to verify needle straightness and presence, compatible with 12–32 gauge needles.

- False: The detector requires manual calibration for each use; in reality, it automatically verifies needle straightness and presence.

Table of Contents

- How Does the Needle Cleaner Enhance Dispensing Accuracy for Camalot Prodigy?

- What Role Does the Needle Detector Play in Maintaining Consistent Performance?

1. How Does the Needle Cleaner Enhance Dispensing Accuracy for Camalot Prodigy?

As a dispensing process expert, I can confirm that the Needle Cleaner and Detector for Camalot Prodigy represents a critical advancement in maintaining consistent dispensing quality through automated cleaning and verification capabilities.

1.1 Key Advantages

- Vacuum-based cleaning station for consistent needle cleanliness

- Automatic detection of needle straightness and presence

- Compatible with 12-32 gauge needles

- Integrated with built-in weight scale

- Real-time process monitoring capabilities

1.2 Process Excellence

The Needle Cleaner and Detector for Camalot Prodigy utilizes a sophisticated vacuum-based cleaning station that automatically removes material buildup from dispensing needles. This preventive maintenance approach ensures consistent material flow and eliminates the risk of clogged needles affecting dispensing accuracy.

The system’s integrated detection capabilities provide continuous monitoring of needle condition, automatically verifying straightness and presence throughout the production process. The Needle Cleaner and Detector for Camalot Prodigy works in conjunction with the built-in weight scale to maintain process stability, ensuring repeatable results and reducing the risk of defects in high-volume production environments.

Claims:

- True: A needle cleaner on a Camalot Prodigy dispenser enhances dispensing accuracy by preventing material buildup and contamination on the needle tip, which can lead to inconsistent droplet sizes and placement, thus ensuring a more precise and repeatable dispense process with each application.

- False: The system requires specialized cleaning solutions; in fact, it uses standard vacuum-based cleaning technology compatible with all standard needle sizes.

2. What Role Does the Needle Detector Play in Maintaining Consistent Performance?

As a dispensing systems expert, I can confirm that the Needle Cleaner and Detector for Camalot Prodigy plays a crucial role in maintaining consistent performance through its advanced detection and verification capabilities.

2.1 Performance Metrics

| Feature | Benefit |

|---|---|

| Gauge Compatibility | 12-32 gauge needles |

| Detection Type | Automated verification |

| Inspection | Straightness and presence |

| Integration | Built-in weight scale |

| Maintenance | Vacuum-based cleaning |

2.2 Advanced Process Control

The Needle Cleaner and Detector for Camalot Prodigy utilizes sophisticated detection technology to continuously monitor needle condition, ensuring optimal dispensing performance. By automatically verifying needle straightness and presence, the system prevents defects before they occur, maintaining consistent material flow and precise dot placement throughout production runs.

The integration of the Needle Cleaner and Detector for Camalot Prodigy with the built-in weight scale provides comprehensive process monitoring capabilities. This combination ensures that material flow remains stable and repeatable, while the automated detection system prevents issues related to bent or missing needles that could compromise dispensing accuracy.

The system’s ability to work with a wide range of needle gauges (12-32) makes the Needle Cleaner and Detector for Camalot Prodigy exceptionally versatile. The vacuum-based cleaning station automatically removes material buildup, while the detector’s continuous monitoring capabilities ensure that dispensing parameters remain within specification, significantly reducing the risk of defects in high-volume production environments.

Claims:

- True: A vacuum-based cleaning station ensures cleanliness of needle/nozzle. A detector is used to verify needle straightness and presence, compatible with 12–32 gauge needles.

- False: The detector system requires manual calibration between production runs; in fact, it operates automatically without operator intervention.

Conclusion

The Needle Cleaner and Detector for Camalot Prodigy represents a critical advancement in automated dispensing technology. Its vacuum-based cleaning station ensures consistent needle cleanliness while working seamlessly with needles ranging from 12 to 32 gauge. The automated detection system verifies needle straightness and presence in real-time, preventing defects before they occur. When combined with the built-in weight scale, this integrated solution delivers exceptional process stability and reliability while minimizing maintenance requirements and production interruptions.

Frequently Asked Questions

1. What role does the needle cleaner play in the Camalot Prodigy?

The needle cleaner in the Camalot Prodigy uses a vacuum-based system to ensure that needles remain free of material buildup, which helps maintain consistent flow rates and prevents clogs during high-volume production runs 2.

2. How does the needle detector contribute to maintaining consistent performance?

The needle detector automatically verifies the straightness and presence of needles, ensuring accurate material deposition and preventing defects caused by bent or missing needles. This feature is crucial for maintaining high-quality output in demanding manufacturing environments14.

3. Are there any manual interventions required for the needle cleaning and detection system?

No, the Camalot Prodigy’s needle cleaning and detection system operates automatically, reducing the need for manual intervention and allowing operators to focus on optimizing production processes14.

External Links Recommendation

- Top Camalot Prodigy Dispenser Features You Need to Know

Explore the advanced features of the Camalot Prodigy, including its needle cleaner and detector, which are crucial for maintaining high-volume production efficiency and quality control.

Source: SMTComponents - The Ultimate Guide to the Camalot Prodigy Dispenser

This guide provides an in-depth look at the Camalot Prodigy’s capabilities, highlighting its precision dispensing technologies and maintenance features like the needle cleaner and detector.

Source: ITW EAE