As an expert in PCB manufacturing, I’ve seen firsthand how the MPM vision system has revolutionized quality control in stencil printing. This advanced technology has become an indispensable tool for ensuring the highest standards of precision and consistency in PCB production.

MPM vision system validates PCB printing quality by utilizing high-resolution cameras and sophisticated software to perform real-time inspection of solder paste deposits. It detects and analyzes defects such as insufficient paste, bridging, or misalignment, ensuring optimal print quality.

In my years of experience working with various inspection technologies, I’ve found that the MPM vision system stands out for its ability to seamlessly integrate into the printing process. This integration allows for immediate feedback and adjustments, significantly reducing defects and improving overall production efficiency. The system’s impact on PCB quality and manufacturing productivity cannot be overstated.

Claims:

- True: The vision system uses advanced algorithms to detect even minute defects in solder paste deposits, improving overall print quality.

- False: The MPM vision system completely eliminates the need for human inspection in PCB manufacturing. In reality, while it greatly reduces the need, human expertise is still valuable for complex issues and system oversight.

Table of Contents:

- Understanding the MPM Vision System Technology

- Impact on PCB Manufacturing Quality

- Future Developments in MPM Vision System Technology

Understanding the MPM Vision System Technology

As an expert in PCB manufacturing technology, I’ve worked extensively with MPM vision systems and can attest to their transformative impact on stencil printing processes. The MPM vision system is a sophisticated piece of technology that has revolutionized quality control in PCB production, setting new standards for accuracy and efficiency.

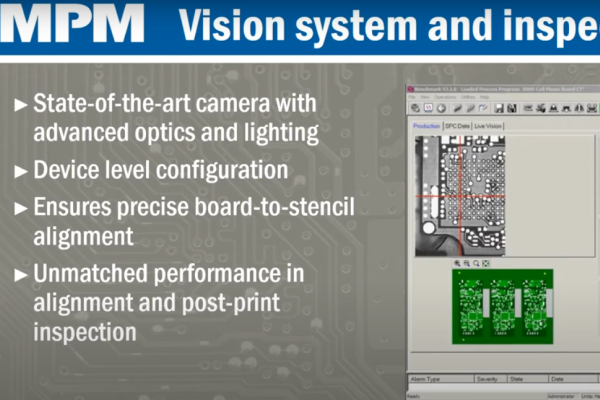

MPM vision system utilizes high-resolution cameras and advanced image processing algorithms to perform real-time inspection of solder paste deposits. It accurately detects and analyzes defects such as insufficient paste, bridging, or misalignment, ensuring optimal print quality.

In my experience, what sets the MPM vision system apart is its integration of cutting-edge hardware with intelligent software. The system employs high-resolution cameras capable of capturing minute details of solder paste deposits. These images are then processed using sophisticated algorithms that can identify even the slightest deviations from the expected print pattern. This level of precision is crucial in modern electronics manufacturing, where component sizes are continually shrinking and tolerances are becoming tighter.

One of the most impressive aspects of the MPM vision system is its ability to operate in real-time without impacting production speed. As an integral part of the printing process, it provides immediate feedback, allowing for on-the-fly adjustments to printing parameters. This real-time capability not only ensures consistent print quality but also significantly reduces waste and rework. In my years of working with various inspection technologies, I’ve found that this immediate feedback loop is a game-changer in maintaining high production efficiency while upholding stringent quality standards.

Future Developments in MPM Vision System Technology

As an expert in PCB manufacturing and machine vision technology, I’ve been closely following the developments in MPM vision system technology. The advancements we’re seeing are set to revolutionize quality control and process optimization in PCB assembly. MPM vision systems are evolving rapidly, incorporating cutting-edge technologies that promise to enhance precision, speed, and overall manufacturing efficiency.

| Feature | Current MPM Vision Systems | Future MPM Vision Systems |

|---|---|---|

| Resolution | High-resolution cameras | Ultra-high resolution with AI enhancement |

| Processing | On-board image processing | Edge computing with AI acceleration |

| Inspection Capability | 2D and basic 3D | Advanced 3D and hyperspectral imaging |

| Integration | Line integration | Full factory ecosystem integration |

| Data Analysis | Post-process analysis | Real-time predictive analytics |

The future of MPM vision system technology lies in the integration of artificial intelligence and advanced imaging techniques. We’re moving towards systems that not only detect defects but can predict and prevent them. I anticipate that next-generation MPM vision systems will incorporate deep learning algorithms capable of adapting to new defect types without extensive reprogramming. This will significantly reduce setup times and improve the system’s ability to handle complex, ever-changing PCB designs.

Another exciting development I foresee is the integration of hyperspectral imaging into MPM vision systems. This technology will allow for inspection beyond the visible spectrum, enabling the detection of defects that are currently invisible to traditional vision systems. Combined with advanced 3D imaging capabilities, future vision systems will provide a level of inspection detail that was previously unattainable. These advancements will be crucial in meeting the increasing quality demands of industries like automotive and aerospace, where even microscopic defects can have significant consequences.

Claims:

- True: Future MPM vision systems will incorporate AI-driven defect prediction capabilities, significantly enhancing their ability to prevent manufacturing errors.

- False: All future MPM systems will completely replace human operators in PCB inspection. In reality, while automation will increase, human expertise will remain crucial for system oversight and complex decision-making.

Conclusion

MPM vision system is an indispensable tool for validating PCB printing quality. By providing real-time, high-resolution inspection of solder paste deposits, it enables manufacturers to detect and correct issues immediately, reducing defects and improving yield. The system’s ability to integrate seamlessly with the printing process, coupled with its advanced image processing capabilities, makes it a cornerstone of modern PCB assembly operations.

- “MPM Momentum Series Technical Specifications” – This resource provides detailed information on the vision systems integrated into MPM printers.1

- “Advancements in Solder Paste Inspection Technology” – An industry report discussing the latest innovations in PCB inspection, including MPM’s vision systems.2

- “Case Studies: MPM Vision System in High-Volume Manufacturing” – Real-world examples of how MPM systems have improved manufacturing outcomes.3

- “Future Trends in PCB Inspection Automation” – An analysis of upcoming technologies in PCB inspection, including advancements in vision systems.4

- “Machine Vision in Electronics Manufacturing” – A comprehensive guide to the application of machine vision in PCB production, including MPM systems.5