As a maintenance specialist with years of experience, I can confirm that MPM Spare Parts for Momentum vision and printhead components are crucial for maintaining precise alignment and print quality in high-volume manufacturing environments.

MPM Spare Parts for Momentum system includes essential components like the Vision X Assembly (2002017) for accurate fiducial alignment and the Left Printhead Assembly (2002016) for consistent print performance. These Level 2 critical components directly impact the printer’s core functionality and precision capabilities.

MPM Spare Parts for Momentum represents a comprehensive approach to maintaining the printer’s advanced features, where proper maintenance of vision and printhead components ensures the system maintains its high-speed performance while delivering superior print accuracy.

Claims:

- True: The MPM Momentum II BTB stencil printer design allows two printers to be configured back to back, creating a dual-lane solution that nearly doubles throughput.

- False: Vision and printhead components require daily calibration; in fact, they feature advanced self-calibration capabilities for consistent performance.

Table of Contents

- How Does MPM Spare Parts for Momentum Vision System Ensure Accuracy?

- What Makes MPM Spare Parts for Momentum Printhead Components Essential?

- Why Are MPM Spare Parts for Momentum Critical for High-Volume Production?

- Conclusion

- Frequently Asked Questions

1. How Does MPM Spare Parts for Momentum Vision System Ensure Accuracy?

As a vision systems specialist, I can confirm that MPM Spare Parts for Momentum vision components are essential for maintaining the printer’s exceptional alignment repeatability of ±12.5 microns @ 6 sigma, Cpk ≥ 2.

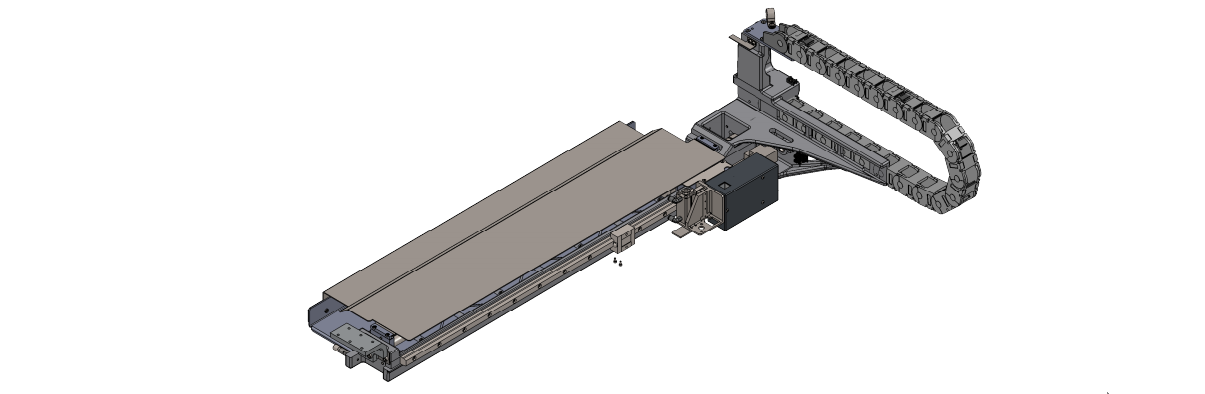

1.1 Mpm Printer Critical Vision X Components (ITW EAE)

| PARTS LIST | ||||

| ITEM | PART NO . | DESCRIPTION | QTY | UM |

| 1 | 1014372 | FLAG,PRINTHEAD Y | 2 | EA |

| 2 | 1014448 | BLOCK, SUPPORT BEARING, VISION X | 1 | EA |

| 3 | 1014450 | MOUNT, CABLE CARRIER, VISION Y | 1 | EA |

| 4 | 1014458 | BRACKET, SENSOR MOUNT | 1 | EA |

| 5 | 1014462 | CARRIER, CABLE, 25mm X 25mm X 75mm, 21 LINK, ASSY | 1 | EA |

| 6 | 1014605 | BALLSCREW,VISION X,15MM DIA,10MM LEAD | 1 | EA |

| 7 | 1014729 | BRACKET, SENSOR WIPER/VISION | 1 | EA |

| 8 | 1014850 | SHIELD, VISION X BALLSCREW | 1 | EA |

| 9 | 1014984 | BLCOK, MOUNTING, CAMERA RAIL | 1 | EA |

| 10 | 1015009 | COVER, CABLE, FRONT, VISION GANTRY | 1 | EA |

| 11 | 1015128 | FLEXURE, VISION GANTRY | 1 | EA |

| 12 | 1015129 | MOUNT, FLEXURE, VISION GANTRY | 1 | EA |

| 13 | 1015130 | PLATE, NUT, FLEXURE | 1 | EA |

| 14 | 1015314 | GANTRY,VISION XY,SUB-ASSY | 1 | EA |

| 15 | 1015504 | CAP, BEARING, BALL SCREW | 1 | EA |

| 16 | 1015505 | WASHER, LABYRINTH, BEARING | 1 | EA |

| 17 | 2005758 | MOTOR, ROTORY STEPPER,3 .0N .M,6.0A,3 STACK,ASSY | 1 | EA |

| 18 | 1015913 | LATCH, WIPER, ASSY | 1 | EA |

| 19 | 1016348 | GUIDE, VISION X COVER | 2 | EA |

| 20 | 1016364 | COVER, CABLE, VISION X | 1 | EA |

| 21 | 2001038 | HARD STOP, M4,VY,MPM BTB | 2 | EA |

| 22 | 2001061 | TRAY, CABLE CARRIER, VISION X | 1 | EA |

| 23 | 2001062 | BRACKET, SUPPORT, VISION X TRAY | 2 | EA |

| 24 | 2001063 | MOUNT, CABLE, CARRIER, VISION X | 1 | EA |

| 25 | 2001064 | COVER, GANTRY, VISION | 1 | EA |

| 26 | 2001065 | FLAG,PRINTHEAD Y | 1 | EA |

| 27 | P0370 | TAPE, ADHESIVE UHMW, .010 THK X 3.0 W,POLYETHEYLENE | 67 | IN |

| 28 | P0846 | BEARING, S ROW BALL, 10MM X 30MM X 9MM, 2SHD | 1 | EA |

| 29 | P2040 | CLAMP, WIRE/CABLE, 3/4, NYLON, BLK | 1 | EA |

| 30 | P2379 | SENSOR,PHOTOELECTRIC, L-SHAPE,24V | 2 | EA |

| 31 | P2775 | CLAMP, WIRE/CABLE, 1/2, NYLON, BLK | 1 | EA |

| 32 | P4086 | ADHESIVE, THREADLOCK, REMOVABLE, 222, 250ML, PUR | 1 | EA |

| 33 | P4087_ | ADHESIVE,242 THREADLOCK,250ml BOTTLE,BLUE | 1 | OZ |

| 34 | P9698 | MOUNT, WIRE, TIE, #6 | 5 | EA |

| 35 | P10032 | BEARING,ANG CONTACT, BALL,12MM X 32MM X 10MM | 2 | EA |

| 36 | P10036 | NUT, BEARING LOCK M12 X 22MM X 8MM | 1 | EA |

| 37 | P60423/P10232 | BEARING,LINEAR,15MM X 14 .5MM X 820MM, 2 CARS | 1 | EA |

| 38 | P10587 | COUPLING, DISC, 10MM X 3/8 X 45 .5MM, ALUMINUM | 1 | EA |

| 39 | P10593 | BUMPER, 12MM OD X 4MM ID X 15MM L, RUBBER | 2 | EA |

| 40 | P11235 | PUSHER,URETHANE,10MM OD X 15MM X M5 SS THREAD | 2 | EA |

1.2 System Performance Optimization

MPM Spare Parts for Momentum vision system maintains its high accuracy through regular replacement of critical components. I recommend implementing a proactive maintenance schedule for vision components to ensure consistent performance. This includes regular inspection of camera assemblies, cables, and lighting systems to maintain the printer’s wet print accuracy of 20 microns @ 6 sigma.

Component compatibility is crucial for the MPM Spare Parts for Momentum vision system. Using genuine parts ensures seamless integration with the Benchmark software interface and maintains the system’s advanced capabilities, including automatic fiducial recognition and alignment correction.

Quality control for MPM Spare Parts for Momentum vision components involves regular calibration and verification procedures. I suggest implementing a systematic approach to vision system maintenance, including periodic testing of alignment accuracy and camera performance to ensure consistent results in high-volume production environments.

Claims:

- True: MPM spare parts for the Momentum Vision System ensure accuracy by maintaining the precision of critical components like the vision gantry, camera system, and alignment mechanisms, which are designed with high-quality materials, precise tolerances, and robust construction, allowing for consistent and repeatable image capture and board placement, ultimately leading to accurate solder paste deposition on printed circuit boards.

- False: Vision system components require daily replacement; in fact, they are designed for extended operation with proper maintenance schedules.

2. What Makes MPM Spare Parts for Momentum Printhead Components Essential?

As a maintenance specialist, I can confirm that MPM Spare Parts for Momentum printhead components are fundamental to maintaining the printer’s exceptional ±20 microns @ 6σ wet print accuracy and ensuring consistent high-quality output in demanding production environments.

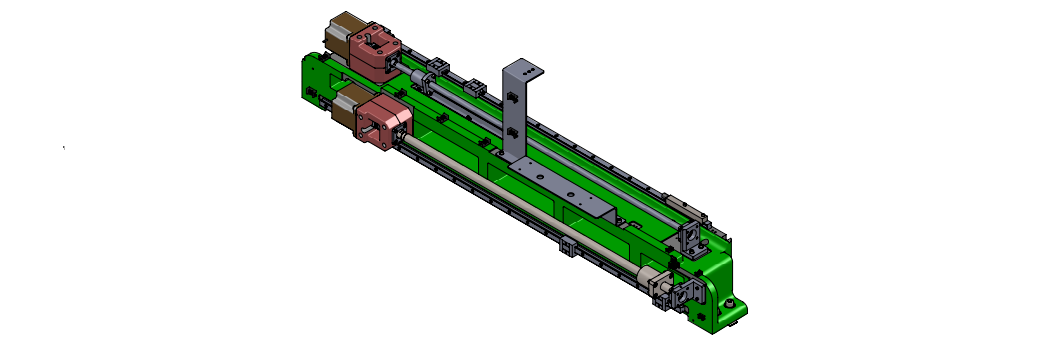

2.1 Mpm Printer Critical Printhead Left Components (ITW EAE)

| PARTS LIST | ||||

| ITEM | PART NO. | DESCRIPTION | QTY | UM |

| 1 | 1014171 | BLOCK, MOUNTING, MOTOR | 2 | EA |

| 2 | 1014348 | BRACKET, CABLE CARRIER | 1 | EA |

| 3 | 2005757 | MOTOR, ROTORY STEPPER,4.5N.M,8.6A,1 SHAFT,ASSY | 1 | EA |

| 4 | 1014606 | BALLSCREW,VISION Y,20MM DIA,10MM LEAD | 1 | EA |

| 5 | 2006133/1014609 | BALLSCREW, 15MM DIA X 16MM LEAD, PRINT Y | 1 | EA |

| 6 | 1014922-03 | SHIM, PRINTHEAD, .03MM THICK, 304SS | 2 | EA |

| 7 | 1014922-08 | SHIM, PRINTHEAD, .08MM THICK, 304SS | 2 | EA |

| 6 | 1014922-13 | SHIM, PRINTHEAD, .13MM THICK, 304SS | 2 | EA |

| 9 | 1014922-25 | SHIM, PRINTHEAD, .25MM THICK, 304SS | 2 | EA |

| 10 | 1014922-50 | SHIM, PRINTHEAD, .50MM THICK, 304SS | 2 | EA |

| 11 | 1014996 | BLOCK, SUPPORT, FRONT, VISION Y | 2 | EA |

| 12 | 1014997 | BLOCK, BEARING, FRONT, VISION Y | 2 | EA |

| 13 | 1015026 | BRACKET,MOUNTING,SINGLE CONTROL INTERFACE MODULE | 1 | EA |

| 14 | 1015298 | FLAG, PRINT Y | 1 | EA |

| 15 | 1015504 | CAP, BEARING, BALL SCREW | 2 | EA |

| 16 | 1015505 | WASHER, LABYRINTH, BEARING | 2 | EA |

| 17 | 1015561 | SUPPORT, PRINTHEAD, LH, MACHINING | 1 | EA |

| 18 | 2005762 | MOTOR, ROTORY STEPPER,3.5N.M,9.9A,1 STACK,ASSY | 1 | EA |

| 19 | 1020006 | BRACKET, HEAD Y, HARDSTOP | 1 | EA |

| 20 | 10000151 | BEARING, S ROW BALL, 12MM X 32MM X 10MM, 2SHD | 2 | EA |

| 21 | 10041751 | MOUNT, SCREW, CABLE TIE, #8-#10 SCREW | 7 | EA |

| 22 | 10048241 | BRACKET, STOP | 1 | EA |

| 23 | P2379 | SENSOR,PHOTOELECTRIC, L-SHAPE,24V | 1 | EA |

| 24 | P9698 | MOUNT, WIRE, TIE, #6 | 3 | EA |

| 25 | P10032 | BEARING,ANG CONTACT, BALL,12MM X 32MM X 10MM | 4 | EA |

| 26 | P10036 | NUT, BEARING LOCK M12 X 22MM X 8MM | 2 | EA |

| 27 | P10177 | COUPLING, BELLOWS, 10MM X 1/2 X 40MM, ALUMINUM | 2 | EA |

| 28 | P60422/P10231 | BEARING, LINEAR, 15MM X 14.5MM X 1180MM, 2 CARS | 1 | EA |

| 29 | P60425/P10236 | BEARING,LINEAR,15MM X 14.5MM X 1060MM, 2 CARS | 1 | EA |

| 30 | P60426/P10238 | BEARING, LINEAR, 15MM X 14.5MM X 1000MM, 2 CARS | 1 | EA |

| 31 | P10593 | BUMPER, 12MM OD X 4MM ID X 15MM L, RUBBER | 2 | EA |

2.2 Strategic Implementation

MPM Spare Parts for Momentum printhead components ensure precision printing through advanced features like closed-loop pressure control and servo-driven systems. The combination of these components maintains the industry-leading accuracy required for fine-pitch applications and dense PCB layouts.

The integration of MPM Spare Parts for Momentum printhead components optimizes performance through sophisticated motion control and vision alignment systems. This ensures consistent material deposition and maintains the printer’s high-speed capabilities while delivering superior print quality.

To minimize downtime, I recommend maintaining an inventory of critical MPM Spare Parts for Momentum printhead components. This proactive approach, combined with the system’s quick-change features, ensures rapid recovery from any potential issues while maintaining production efficiency.

For consistent quality, the MPM Spare Parts for Momentum printhead components work together with advanced features like EnclosedFlow™ print head technology. This integration delivers uniform aperture filling and superior printing performance, especially for fine-pitch devices.

Claims:

- True: MPM spare parts for Momentum printhead components are essential because they enable continuous, high-precision printing operations on a stencil printer by allowing for the replacement of worn-out parts like squeegee blades, seals, and apertures, which are critical for maintaining consistent solder paste deposition and preventing defects, ultimately ensuring optimal production uptime and yield in electronics manufacturing processes.

- False: Printhead components require daily replacement; in fact, they are designed for extended service life with proper maintenance.

3. Why Are MPM Spare Parts for Momentum Critical for High-Volume Production?

As a maintenance specialist, I can confirm that MPM Spare Parts for Momentum are essential for maintaining continuous operation in high-volume manufacturing environments, where even minor interruptions can significantly impact production yields and quality standards.

3.1 Critical Components for Production

- High-precision components ensure ±12.5µm accuracy @ 6σ

- Minimal downtime through quick-change modules

- Reliable performance with Level 1 and 2 spare parts

- Fast changeover times with plug-and-play architecture

- Optimized for high throughput with dual-lane capabilities

3.2 Strategic Implementation

MPM Spare Parts for Momentum system requires a proactive maintenance strategy to support its high-speed capabilities. I recommend implementing a comprehensive spare parts inventory system that includes both Level 1 wear items for annual maintenance and Level 2 critical components to prevent unexpected downtime.

To maximize production efficiency, the MPM Spare Parts for Momentum should be managed through a strategic approach that includes regular monitoring of component wear patterns, establishing reorder points, and maintaining detailed maintenance records. This ensures continuous operation while maintaining the printer’s impressive wet print accuracy of 20µ @ 6σ, Cpk ≥ 2.

Claims:

- True: MPM spare parts for the Momentum stencil printer are critical for high-volume production because the Momentum is designed for high-speed, precision printing, and having readily available spare parts ensures minimal downtime in case of wear and tear, allowing production to continue smoothly without significant interruptions, especially when dealing with large production runs.

- False: All spare parts require specialized tools for replacement; in fact, many components feature plug-and-play architecture for quick maintenance.

4. Conclusion

MPM Spare Parts for Momentum II vision and printhead components are essential for maintaining optimal performance and precision in high-volume manufacturing. The Vision X Assembly (2002017) ensures accurate fiducial alignment while the Left Printhead Assembly (2002016) maintains consistent print quality. These Level 2 critical components support the system’s impressive ±12.5µm accuracy @ 6σ and wet print accuracy of 20µ @ 6σ, Cpk ≥ 2. A proactive maintenance strategy with proper inventory management of these components ensures maximum uptime and production efficiency.

5. Frequently Asked Questions

1. What critical components are included in the Vision X Assembly (2002017)?

The Vision X Assembly includes digital up/down cameras, advanced alignment systems, and automated vision correction capabilities that ensure precise fiducial alignment with ±12.5µm accuracy @ 6σ25.

2. How does the Left Printhead Assembly (2002016) maintain consistent performance?

The printhead assembly uses precision ball screws and linear guides instead of belt-driven motions, eliminating the need for calibrations while providing higher repeatability and reliability1.

3. What maintenance is required for the vision and printhead systems?

Both systems feature plug-and-play architecture for quick maintenance, with minimal calibration requirements due to the advanced servo-driven design and auto-tune capabilities3.

- ITW EAE Support Center – Vision System Components

Access comprehensive documentation for Vision X Assembly (2002017) components, including camera systems, lighting, and calibration tools for maintaining optimal alignment accuracy.

Source: ITW EAE Support - SMT Components – MPM Printhead Parts Guide

Detailed catalog featuring Left Printhead Assembly (2002016) components, including servo motors, control boards, and printhead maintenance kits.

Source: SMT Components - MPM Momentum Series Technical Documentation

Complete technical documentation covering vision system calibration, printhead maintenance procedures, and recommended spare parts inventory management.

Source: MPM Technical Library - Speedline Technologies Vision and Printhead Database

Comprehensive database of genuine MPM parts for vision and printhead systems, including advanced features like digital up/down camera components and print force control systems.

Source: Speedline Technologies