As someone who has spent years in the electronics manufacturing industry, I can confidently say that the efficiency of your production line hinges significantly on the reliability of your equipment. Among the most critical components in this equation are the spare parts for your MPM screen printers. These machines are integral to high-quality printing applications, and having access to the right spare parts can mean the difference between a smooth operation and costly downtime. But how exactly can MPM screen printer spare parts enhance your production efficiency?

When it comes to maintaining your MPM screen printers, having a reliable source for spare parts is essential. This not only ensures that you can quickly replace worn or damaged components but also helps maintain the overall performance of your printing processes. Below, I’ve compiled a list of key benefits that illustrate how these spare parts contribute to enhanced production efficiency:

- Minimized Downtime: Quick access to spare parts reduces the time your machines are out of operation.

- Consistent Quality: Replacing worn components ensures that print quality remains high and consistent.

- Cost-Effectiveness: Investing in spare parts can prevent more significant repairs or replacements down the line.

- Improved Machine Longevity: Regular maintenance with quality parts extends the life of your printers.

- Enhanced Productivity: Reliable machinery allows for uninterrupted production runs.

With this understanding, let’s transition into a deeper exploration of how specific spare parts can impact your operations.

Contents

- What Are MPM Screen Printer Spare Parts?

- Why Are Quality Spare Parts Essential?

- How to Choose the Right Spare Parts?

- Where to Source MPM Spare Parts?

- How Can Regular Maintenance Improve Efficiency?

What Are MPM Screen Printer Spare Parts?

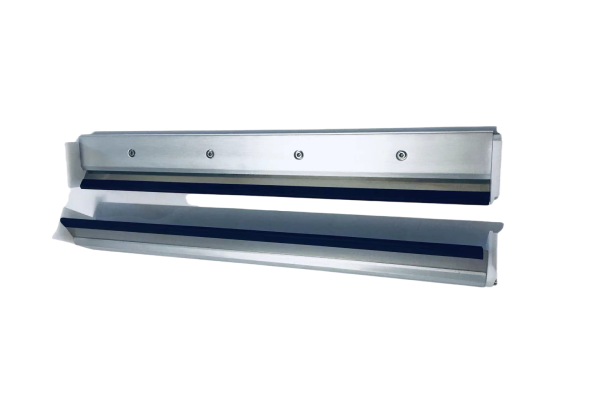

MPM screen printer spare parts encompass a wide range of components designed specifically for MPM printing machines. These include mechanical parts like squeegees, blades, and print heads, as well as electronic components such as sensors and control boards. Each part plays a crucial role in ensuring that the printer operates effectively and produces high-quality prints.

Here is the key MPM Screen Printer Spare Parts:

- Mpm Printer Squeegee Blades Part Number: 1006638, 1018140, 1023036, 2006150, 1024009, 1019813, 1019822, 1017052, 1018374, 1006110, and others.

- ITW EAE Motors Part Number: 1021551,1021552, 1003307, 1003310, 1005804, 2005757, 2005751, 2005752, 1003645, 1003647, 1002440, 2001723, 2001724, 1015137, 1002584, 2001589, 2005541, 2005774, 1016160, 1021498, 2001589, 2006569, 1015576, 1015581, 1015582, 1014373, 1016699, 2005762, 1015802, 1016503, 1015076.

- Speedline Sensors Part Number: 1015390, 1015738, 1014857, 1022151, 1011839, CA-816, 1015657, 1015459, 1015787, 1022157,2006345, 2006346, 2006343, 1014858, 1014863, 2001397, 2001398, 1021977, 2001194, 1022153, 1017237, 1017256, 1017247, 1017248, 1020223, 1021548, 1015707, 1019944, 1019947, 1019945, 1015524, 1021541, 1015078, 1013401, 1011839, P2379, 1015548, 1014836, 1014863.

- Speedline Control Boards Part Number: 1019704, 1019701, 1011119, 1019016, 1019025, 1015792, 1015915, 1021213, P13329, P10455, 1025522, 1019733, 1014150, 1024779, 1024001, 1023803, 1014500, 2002257, 1014182, 1015953, 1017070, 1017661, 1017074, P10098, P60870, P10333, P7775, P7774.

Understanding these components is crucial as it allows you to identify which parts may need replacement during routine maintenance or unexpected breakdowns.

Why Are Quality Spare Parts Essential?

The quality of spare parts directly impacts the performance and reliability of your MPM screen printers. Using subpar or incompatible components can lead to various issues, including poor print quality, increased wear on other machine parts, and even complete operational failure.

Benefits of Using Quality Spare Parts:

- Reliability: High-quality parts ensure consistent performance.

- Compatibility: OEM parts guarantee proper fit and function.

- Performance: Better materials lead to improved durability and efficiency.

- Warranty Protection: Using OEM parts often keeps warranties intact.

Investing in quality spare parts may seem more expensive upfront, but it pays off in terms of reduced maintenance costs and enhanced productivity over time.

How to Choose the Right Spare Parts?

Choosing the right spare parts for your MPM screen printers requires careful consideration of several factors, including compatibility, quality, and supplier reliability.

Tips for Selecting MPM screen printer spare parts:

- Consult Documentation: Always refer to your printer’s manual for part numbers and specifications.

- Check Compatibility: Ensure that any part you purchase is compatible with your specific printer model.

- Research Suppliers: Look for reputable suppliers who specialize in MPM screen printer spare parts.

- Read Reviews: Customer feedback can provide insights into part performance and supplier reliability.

By following these guidelines, you can make informed decisions that will keep your production line running smoothly.

Where to Source MPM Spare Parts?

Finding reliable sources for MPM screen printer spare parts is crucial for maintaining operational efficiency. There are several avenues you can explore:

Recommended Sources for MPM screen printer spare parts:

- OEM Suppliers: The best option for guaranteed compatibility and quality.

- Authorized Distributors: Often have a wide range of stock available.

- Online Marketplaces: Websites like SMTComponents or ITW EAE offer various options but ensure they are reputable sellers 1.

- Local Distributors: Sometimes local suppliers can provide quicker access to needed parts.

By leveraging these sources, you can ensure that you have timely access to the necessary components without compromising on quality.

How Can Regular Maintenance Improve Efficiency?

Regular maintenance is an often-overlooked aspect of keeping your MPM screen printers running at peak performance. By establishing a routine maintenance schedule, you can identify potential issues before they escalate into costly repairs.

Steps for Effective Maintenance:

- Routine Inspections: Regularly check all mechanical and electronic components.

- Cleaning Protocols: Keep machines clean from dust and debris that could affect performance.

- Lubrication: Ensure moving parts are adequately lubricated to prevent wear.

- Record Keeping: Maintain logs of maintenance activities for future reference.

Implementing these practices not only prolongs the life of your equipment but also enhances overall production efficiency by minimizing unexpected downtime.

Conclusion

In conclusion, investing in quality MPM screen printer spare parts is essential for enhancing production efficiency in any electronics manufacturing environment. By understanding the importance of these components, choosing the right suppliers, and implementing regular maintenance practices, you can ensure that your printing operations run smoothly and effectively.

Are you ready to take your production efficiency to the next level by prioritizing spare part management?

- SMT Components – A comprehensive source for SMT equipment and components.

- ITW EAE Printers – Explore advanced printing solutions tailored for electronics manufacturing.

- PPM Parts – Specializes in Speedline and MPM screen printer spare parts with many options available in stock.