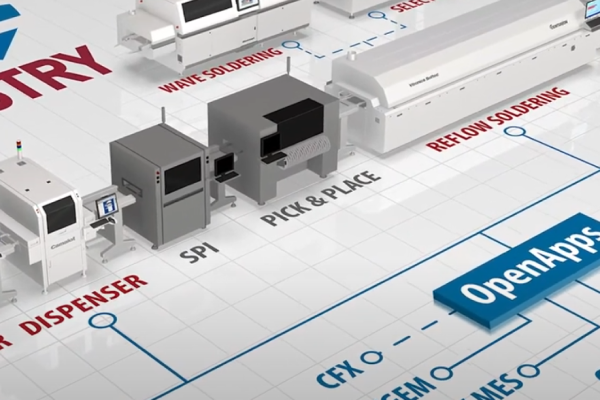

MPM printing solutions for PCB assembly are pivotal in the electronics manufacturing industry, ensuring precision and efficiency in the application of solder paste. These advanced stencil printers are designed to meet the high demands of modern production lines, making them a critical investment for manufacturers aiming to enhance their operational capabilities.

MPM stencil printers are essential for PCB assembly because they ensure precise application of solder paste, significantly enhancing production efficiency and reducing defects. Their advanced technologies enable manufacturers to meet high-quality standards while maintaining cost-effectiveness.

In my extensive experience with MPM printing solutions for PCB assembly, I have observed how these printers transform manufacturing processes. They not only improve the accuracy of solder paste application but also streamline operations, leading to higher product quality and reduced defect rates. This article will delve into the key features and benefits of MPM printers, illustrating why they are indispensable in today’s competitive electronics landscape.

Claims:

- True: MPM printers utilize advanced alignment and printing technologies that enhance the precision of solder paste deposition on PCBs.

- False: While many models are designed for high-volume applications, some may be better suited for lower throughput environments depending on their specifications.

Table of Contents

- Key Features of MPM Stencil Printers

- Benefits of Using MPM printing solutions for PCB assembly: Why Are They Essential?

- Conclusion

Key Features of MPM Stencil Printers

As an expert in PCB assembly, I’ve extensively worked with MPM printing solutions for PCB assembly and can confidently say that their key features set them apart in the industry. These advanced stencil printers are designed to meet the demanding requirements of modern electronics manufacturing, offering a combination of precision, speed, and reliability that is hard to match.

MPM printing solutions for PCB assembly boast key features like closed-loop servo systems, automatic vision alignment, and user-friendly interfaces. These technologies ensure high accuracy, efficiency, and ease of use in PCB production processes.

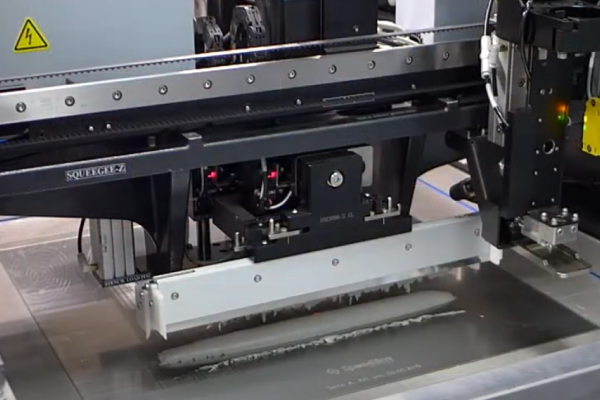

The closed-loop servo system is a cornerstone feature of MPM printing solutions for PCB assembly. This technology continuously monitors and adjusts the printing process in real-time, ensuring consistent and accurate solder paste application across various PCB designs. I’ve seen firsthand how this system minimizes common issues like misalignment, significantly reducing defects in the final product.

In my experience, the precision offered by this system is crucial for meeting the stringent quality standards required in electronics manufacturing. The closed-loop servo system allows for fine-tuning of printing parameters, such as pressure and speed, adapting to different solder paste viscosities and PCB surface finishes. This adaptability is particularly valuable when working with complex, high-density boards that are becoming increasingly common in modern electronics.

Claims:

- True: MPM printing solutions for PCB assembly utilize closed-loop servo systems for real-time adjustments during the printing process.

- False: All stencil printers in the market offer the same level of precision as MPM printers. In reality, MPM’s closed-loop servo system provides superior accuracy compared to many competitors

Benefits of Using MPM printing solutions for PCB assembly: Why Are They Essential?

In my experience with MPM printing solutions for PCB assembly, these printers offer several key benefits that make them essential to modern electronics manufacturing. Their precision, speed, and automation capabilities not only enhance production efficiency but also ensure consistent quality in high-volume environments.

MPM stencil printers are essential in PCB assembly because they provide high precision, increased throughput, reduced defects, and lower operational costs. Their automation features streamline processes, making them indispensable for manufacturers aiming for efficiency and quality.

MPM printing solutions for PCB assembly excel in several areas. First, their advanced alignment systems ensure precise solder paste application, which is critical for reducing defects and improving product quality. Second, the high-speed operation of models like the Momentum II allows manufacturers to meet tight deadlines without sacrificing accuracy. These features are particularly beneficial in high-volume production environments where both speed and precision are paramount.

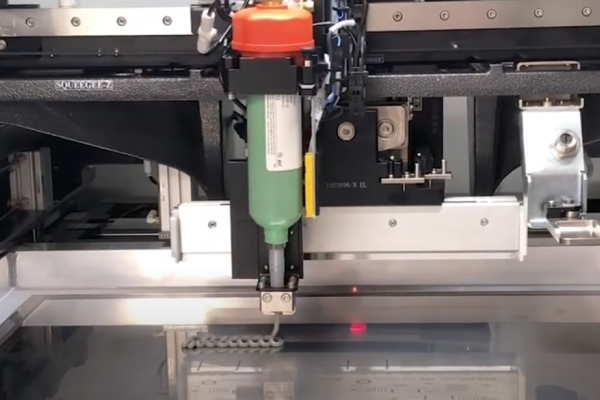

MPM printers offer significant cost savings over time. The automation of key processes—such as paste dispensing and stencil cleaning—reduces manual intervention, leading to fewer errors and less material waste. From my observations, these benefits not only improve overall productivity but also contribute to a reduction in operational costs, making MPM stencil printers a smart long-term investment for any manufacturer.

Claims:

- True: MPM stencil printers reduce defects by utilizing advanced alignment systems that ensure accurate solder paste deposition.

- False: MPM printers increase operational costs due to their advanced features. In reality, their automation leads to lower costs over time by reducing waste and improving efficiency.

Conclusion

MPM printing solutions for PCB assembly have proven to be indispensable in modern electronics manufacturing. Their combination of precision, speed, and automation capabilities addresses the key challenges faced by manufacturers in today’s competitive market. By investing in MPM stencil printers, companies can expect to see improvements in product quality, production efficiency, and overall operational performance.