Get answers to frequently asked questions on MPM Printer equipment as well as troubleshooting tips and tutorials to help resolve common issues.

1.MPM Printer Momentum 100 reports low air pressure during wiping after each wipe change, but not during production 1.

Set the air pressure gauge to 6.5 kg and keep an eye on the gauge while the machine is wiping the stencil.

2.MPM Printer Momentum clipboard position, above the clip edge and below the top strip is not in a straight line, resulting in the clipboard after the PCB bowing, caused by the printing support is not in place, the thinner the board the worse the stability of the printing, the gods to see if there is a good suggestion ?

MPM Printer Momentum is very stable. The quality of the print is determined by the support, and if the support problem is not solved, it will be the same with any other printer.

3.This happens when MPM Printer Momentum processing reports an error, whether it’s stopping or pausing, it just reports this when there’s an action anyway .

Restore a new system will be OK .

4. The MPM Printer Momentum BTB 125 loses power at any time, whether it’s during production, during solder paste application, or during wiping.

Many conditions can cause power loss, such as: abnormal speed of the paper roll motor, frayed wires inside the Y-axis tank chain, frayed camera wires (MPM Printer 125 mostly), loose plugs in the safety circuit nodes, and so on.

5.What is the difference between Stop and Pause on the main screen of the MPM Printer Momentum software ?

Stop is to complete a printing cycle after the board to go out between the exit of the main screen, pause is not complete a cycle on the stop, such as squeegee is printing state .

6.MPM Printer Momentum 100 Y-Axis Reporting Control Motor Error .

The wiping paper lever is too tight .

7. MPM Printer Momentum 24V voltage won’t start .

Power supply is bad, normal phenomenon, 24V power supply can be repaired.

8.MPM Printer 125 lagging and long boot times .

If there are too many files in benchmark, it will be super slow to load on boot, you need to copy out or delete the program files in it regularly.

9.MPM Printer Momentum Motion Error appears in the shaft wiper paperAXiswait Timeout .

Sensor and right hand fastening wheel are fine, wiping motor does not spin .

10.Has the MPM Printer Momentum ever been used for automatic tinning ?

It works fine now, mainly the input/output ratio.

11.MPM Printer 125 press comes standard with 736 mesh frame, 450*550 stencil can’t print properly, do you have any mesh frame recommendation ?

You can buy a stencil adapter, SMTCOMPONENTS CO., LIMITED has this unit .

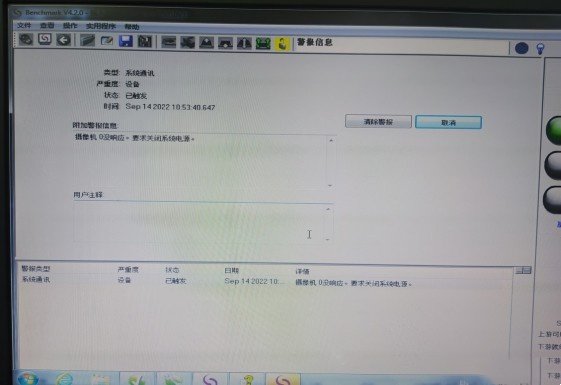

12. MPM Printer momentum+ Error reported in production , Camera 0 is not responding .

1.Stop and check if the camera has an image. 2. Check the image card, connecting cable . 3.Just change the camera cable.

13.MPM Printer 125 press recognises mark jamming

Problems with the camera cable .

14. MPM Printer MOMENTUM Image not connected .

BIOS timing issues .

15.mpm125 printer vacuum pump abnormal sound .

It is time to Cleaning and Maintenance .

16.mpm momentum printer software installation error ,The computer reinstalled the system, now installing software, registered licence, run to install the software is still reporting an error, no licence information 1004, unable to execute getlicenseinfo.exe .

you need buy a new mpm computer , buy it from SMTCOMPONENTS CO., LIMITED .

17.During the printing process of MPM125, the light source of the camera does not light up, and the MARK point cannot be found.

It’s a Camera Cable 1014794 problem, or it’s a bad little plate inside the camera P10333, a round plate.

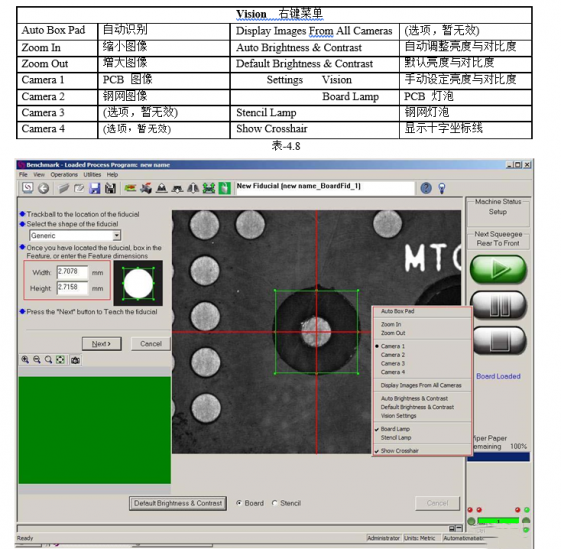

18.How to Adjust Fiducial Mark Brightness for MPM momentum presses .

In the advanced options of the settings mark, lower the requirement for passing from 70 to 50.

19.MPM125 Wipe Failure ,As soon as I opened the auto wipe, it reported an error (as shown in the picture), and after the error was reported, the loading stencil Y-axis sensor just touched the iron sheet when it was directly disconnected !

Look at the Y-axis limit sensor for false signals.

20.mpm 125 alarm 80v lost , After shutting down and restarting, tap initialise and it reports “”80v power lost, re-initialise” .

The 48V power box is broken.

21.MPM125 wiping problem, wiping motor turns sometimes and sometimes not .

Paper Roll Motor 1015802 is broken , Find SMTCOMPONENTS CO., LIMITED to buy this motor .

22.Currently part of the domestic printing machine, some companies produce small orders, in order to save the cost of the stencil, will do two products on a stencil opening, before and after the position of the transfer of production, you can move the position of the stencil, please MPM printing machine can achieve such a production method ?

It’s not recommended.

23.MPM BTB125 Printer Y-axis suddenly rattles in printing, and the squeegee automatically moves back and forth with a serious jittering sound, and after shutting down and restarting, the printing Y-axis jerks and rattles a lot when resetting to zero.

Initial determination of control card failure .

24.MPM Momentum reports an error after recognising Mark points .

Just change the value for Stretch Deformation, it’s in the Impact Advanced Settings.

25.MPM Momentum system crashed, there is no backup of the original host computer, and I got an error when I took the image of another machine, what should I do after restoring the system of another machine?

Mpm Printer Momentum if lisence is lost you have to resort to SMTCOMPONENTS CO., LIMITED . MPM Computer ordering number 1020430 and 1019065 .

26.What is the effect of switching the “Heavy Substrate” function on and off in MPM presses?

Platform rise and fall will be slower, I’ve played with 0.8mm boards before and they don’t pop up easily.

27.MPM125 CCD camera housing was scratched by the net frame, resulting in the photograph MARK when the bias is about 0.13 Now the printing needs to be compensated to brush the right, ask this can be corrected? If so, how do I go about calibrating it ?

Modify the parameters.

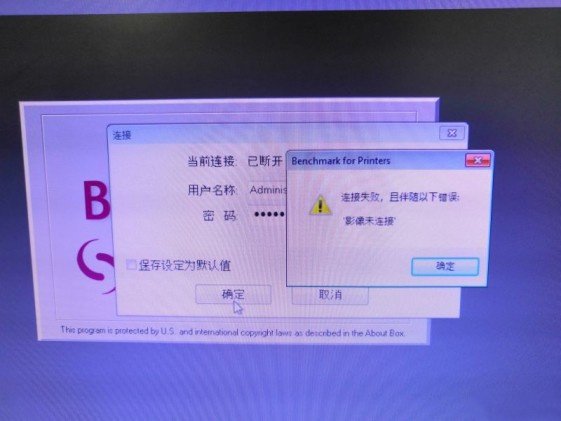

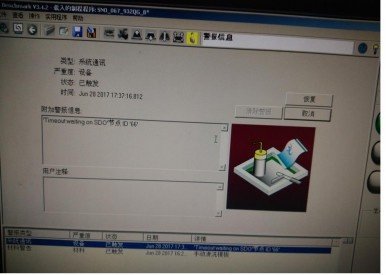

28. MPM 125 booting up and logging in to connect reported a connection failure. Which location could be the problem?

The problem is solved as follows :

1. Shut down and restart, (the problem remains)

2. Enter the SERVICE, disconnect and reconnect, and then restart, (the problem remains)

3. Check the image connected to the CABLE line, the line is not found to be broken, short-circuited, disconnected phenomenon. (fault remains)

4. Replace the BIOS battery, the actual measurement is only 1.3V, the battery is 3V (fault remains)

5. Change the BIOS time from 2012-1-1 to 2019-7-13 after the start OK

6. Warm up for 30 minutes without error (OK)

7. Shut down and restart 3 times without error (OK)

8. New program editing (OK)

9. Actual printing (OK)

10. To be Monday actual production verification. (Tracking)

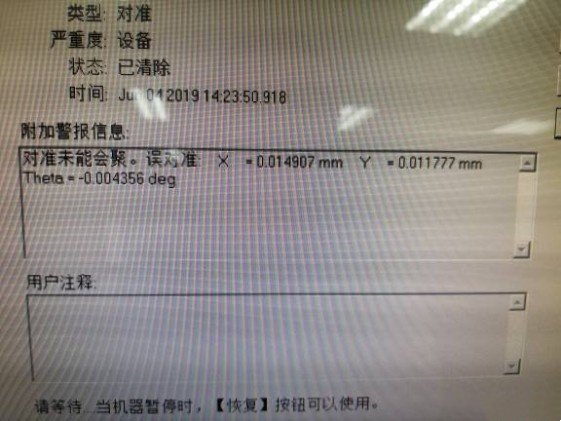

29.MPM Printer Momentum BTB 125 can’t find datum ,Substrate information 480*98mm, when doing the procedure to find the substrate datum, can not be directly illuminated to the corresponding template datum. Alignment has not been able to pass.

MARK points for excessive range deviation! This can be compensated for by reducing the visual education window, as well as the appropriate small range for the feed plate position! If it’s off that way, compensate that way !

30.MPM Printer Momentum keeps reporting wipe empty, does anyone have a way to debug the wipe sensor?

The wipe sensor 1015738 was soaked with alcohol and when it was replaced the machine was back to normal. Need mpm printer sensor 1015738 to get help from SMTCOMPONENTS CO., LIMITED .

31. mpm Printer 100 Auto Squeegee Pressure Cannot Be Corrected

Need to recalibrate the position of the squeegee height sensor .

32. How to activate the 2D check function in MPM Printer 125 .

Contact SMTCOMPONENTS CO., LIMITED to upgrade the host computer license. ITW EAE Speedline MPM Printer 1020430 Computer 1019065 Momentum II .

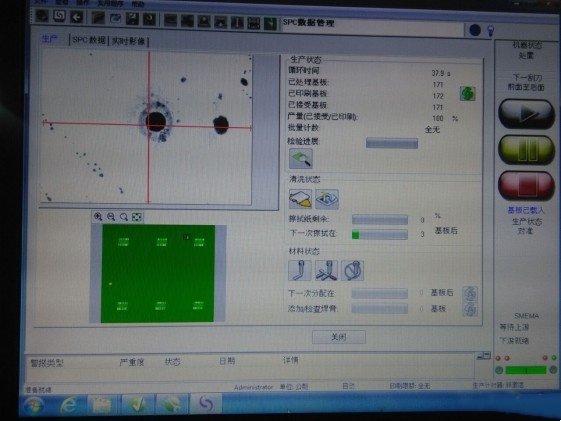

33. MPM Printer Momentum CPK Tutorials .

34. MPM125 reports a shaft error during normal production, initialises just fine and then reports the same error after a while.

The springs in the stencil paper pins check to make sure they don’t have enough spring in them anymore.

35.mpm125 without cleaning paper machine does not alarm, where is the sensor for cleaning paper ?

1.The wiper’s tick has not been used up, yo, if not used up, you produce a day he will not alarm, there will only be abnormal quality problems.

2.That sensor is in a very pitted location, and the alcohol pump can be damaged by alcohol contamination if the recovery goes wrong.

36.MPM125 initialisation 24V lost , Start 24V, no input from GS1 and GS3, K3,K4 do not engage, no 24V! No voltage at switches FR1,2,3! What is the cause of this?GS2 is normal!

MPM Printer Power supply is broken, buy power supply from SMTCOMPONENTS CO., LIMITED . P10109 P9313 P10108 .

37.Reasons for Plugged Holes and Leaks in MPM Printer Momentum BTB

The squeegee didn’t scrape cleanly, or the solder paste warmed back up or the stencil opening was wrong.

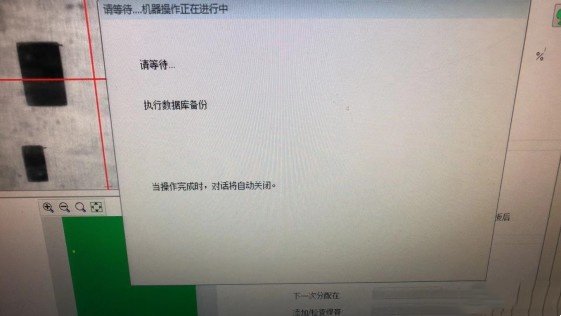

38.MPM Momentum BTB125 shows database being backed up when paused .

Use the BenchmarkSPC.mdb database from the backup to overwrite the file of the same name in the software directory.

39. TIMEOUT when Speedline MPM Momentum 100 front wiper is down .The descent is smooth, no lag, but every now and then the following alarm occurs and needs to be re-initialised to resolve it, and there’s always no good way to resolve it .

1, Z-axis travels without obstruction and moves smoothly

2, whether the sensor lights up

3, whether the I/O changes when the sensor lights up

4, whether the I/O card works normally.

40.MPM Momentum BTB 125 eraser tip is not in the right place anymore, recalibration reports over limit error .The MPM BTB 125 eraser tip is out of position, recalibration reported an over limit error, the limit position is: start point: -406mm, end point: 355mm, recalibration the end point position to 365mm tip to be able to match, where is the problem ?

Does running Vision Y lim to lim report an error? Check to see if the wiping machine backs up properly, and if the spring of the wiping suction mechanism is broken.

41.Can the motherboards of two MPM Printer 125 computers be swapped?

No, each host has a corresponding Licence that is bound to the motherboard. If you want to change only the whole host. If you are testing the motherboard to see if there is a problem, you can exchange the motherboard to test it, and exchange the motherboard to boot up but not reset the machine. Remember to change the motherboard back.

42.MPM Momentum reports “The key to execute this software version is missing.” In the production of the device, the host can not be turned on normally after the shutdown of the main power supply, wipe the memory stick after the computer can be turned on normally, to open the software, click on the device to return to the test point reported that “the implementation of this software version of the key is missing”, the device randomly installed CD-ROM to restore the system, invalid !

If there is no problem with the hard disk or motherboard, the software should be able to be re-injected, if the Key is lost because of damage to the hard disk or motherboard, it is necessary to buy LICENSE from SMTCOMPONENTS CO., LIMITED .

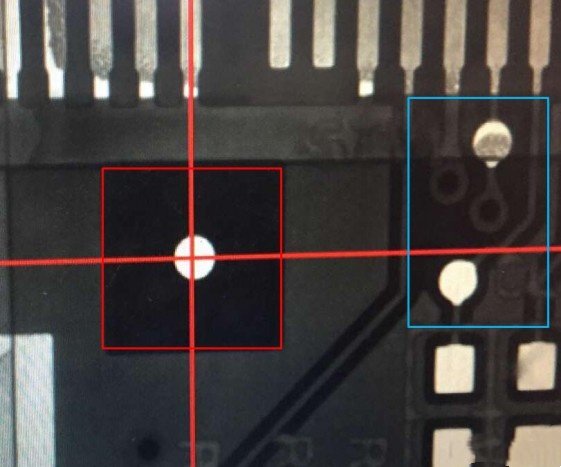

43. MPM125 printer recognises the two test spots circled in blue next to each other when recognising Mark spots, what settings are available to debug the printer !

When you make Mark points, you automatically identify them and then put the outer search box to include the test points next to them, so that this Mark point is unique.

44.Our ITW EAE MPM125+ Printer machine is malfunctioning, that is, as soon as it wipes, the machine alarms “Wiper not unpinned: Y or X limit markings remain”. After initialisation the stencil is loaded with the alarm “Wiper not in (back) parked position”. I checked the sensors at the back and they are fine.

Check to see if the spring inside that pin in the camera’s pull-wipe mechanism is broken, and that the pin is not backed out at the end of the wipe.

45. Speedline MPM125 has been crashing a lot during production lately, when the camera goes to take a picture of the first MARK point, it doesn’t move and the screen displays Processing Baseboard. You have to restart the machine to continue production.

1.There’s something wrong with the Camera Cable 1014794.

2.If you really can’t find the cause, you can ask your equipment supplier to come over and collect the snapshot data, which will then be sent to the original manufacturer for them to analyse the specific cause.

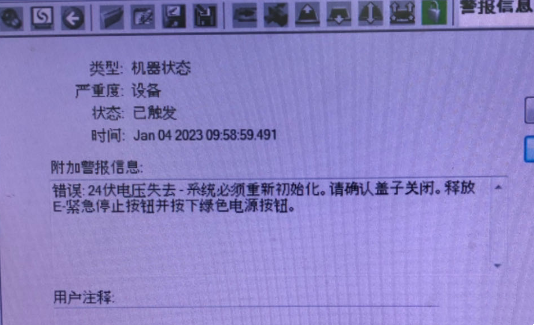

46.MPM Printer 125 Initialisation Error , MPM 125 crash after reboot, the initialisation process reported an error: frontpin pickup initalization failure Error: 24 Volts lost-System must be reinitialized Please frontpin refers to that part ah. Initialisation can be heard inside the machine solenoid valve suction sound, but a open and close, about 5 seconds after the above error.

Stop board cylinder stuck, first control card reset and then check the I/O .

47.We have an 8 year old MPM125 screen printer that recently developed a rear squeegee that would not complete the auto test height. After the automatic test, the front squeegee can normally complete the bright – black – bright test process, after the squeegee will be into the sensor bright – black has not been able to press the stencil down again to the bright process of the error, no matter how up and down the adjustment of the sensor iron and sensor position is the result of this, the manual test is normal, may I ask what other places need to be checked ?

That origin sensor position is required to correct, not just move, corrected if still not work to restore the factory Database .

48.MPM Printer 125 change programme to adjust the track abnormally .

This can be set , See the attached pictures for details .

49.MPM printer Momentum Alcohol recovery is not timely and will jam.

Make sure the solvent pump is original first, the original goes out and comes back with a different flow rate. If it’s original it’s the lines that are clogged with foreign objects and need to be serviced.

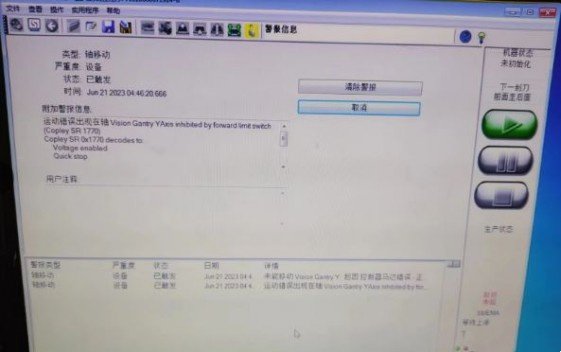

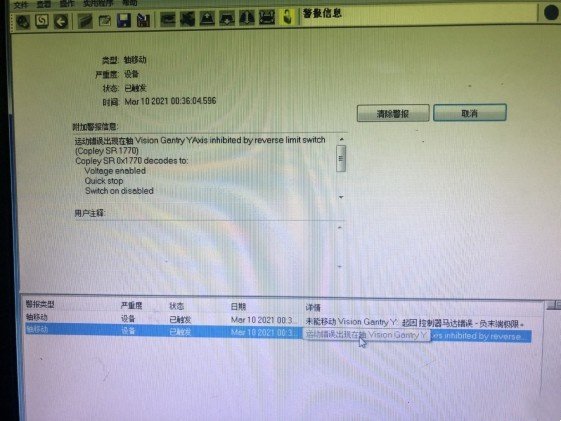

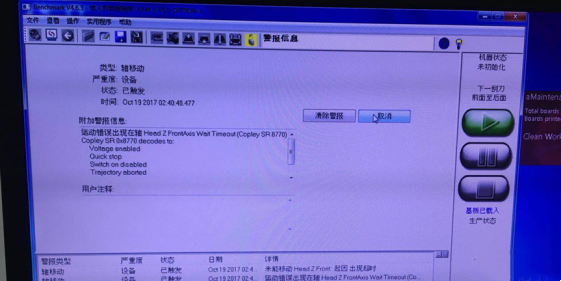

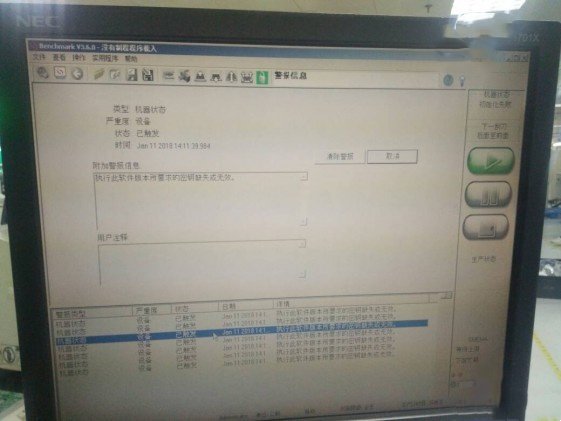

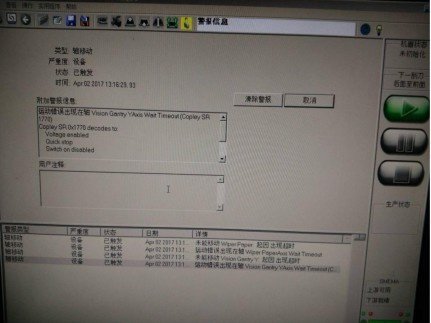

50.Our company’s Speedline mpm Printer 125+ has been dropping power frequently lately, and after initialization it can produce normally again.

Specifically the alarm: Axis Move Motion Error appears in axis Vision Gantry YAxis Wait Timeout

Motion error occurs in axis Vision Gantry XAxis Wait Timeout Motion error occurs in axis Worknest ZAxis Wait Timeout

Failed to move Worknest ZAxis: Cause timeout occurred

Failed to move Vision Gantry YAxis: Cause timeout occurred

Failed to move Vision Gantry XAxis: caused by a timeout .

This machine is the XP version, the first picture you look at the alarm occurs earliest whether it is the first one above, if it is the machine detected that the paper roll motor did not rotate. The second picture is not detected by Node66, this problem is generally wiping mechanism wire slot inside the signal line short circuit or node66 control card problems. Both alarms have to do with wiping, to check the signal line.

51.How do I calibrate the print offset on the MPM125 Printer ? Compensate for XY 0.2MM every time you do a programme after the camera hits the fixture .

In the Calibration menu there is a Change Origin Offset .

52.What is the problem with the MPM125 printer that all of a sudden there is no signal from the plate feeder and no signal from the Conveyor ?

Is the smema line connected two or four? If you connect two of the two 24V signal wires of the printing press to be shorted, this signal on the signal is upstream ready signal. If you connect four depends on the four indicator lights in the lower right corner of the printing machine.

53.MPM125 Rear Squeegee Cannot Complete Height Detection . The front can do a good job is the back scraper can not be automatically completed. Attention to observe the normal front squeegee, squeegee in the process of doing height, the initial sensor is bright, in the squeegee just touched the mesh plate when the sensor is dark, squeegee and then downward pressure for a distance, the sensor is bright again, the system will be the distance recorded into the height of the squeegee. After the scraper can also be completed by the process of light to dark is the scraper pressed on the steel mesh to continue down to the sensor again after not yet bright on the error. I’ve adjusted the position of the sensor iron up and down, sometimes with occasional success, but only for a little while. I can confirm that the sensor is well fixed, what else could be the cause?

There is standard data for this sensor adjustment, 5.5 – 6.5lbf. It needs to be calibrated with a squeegee pressure gauge .

54.After the mpm125 was printed, there was a noise after the platform was lowered .

The bottom Z-axis motor brake is broken .

55.mpm125 screenwiper limit error report .Initialisation is normal, the scrubber works fine from back to front, but alarms when it returns to the standby position of the rear scrubber.

It should be that the spring in the fixed block of the camera going to pull the wiping mechanism broke and the pin didn’t back out.

56.Our company a MPM Printer 125, work found that the substrate is fixed, according to the MARK start, Table rise after the top pin, the substrate is completely higher than the side of the edge of the clamp, until the end of the printing Is this the case?

If the blade is not clamped, the Table rises above the image height PCBs all exceed the track height .

57. MPM Printer 125 Wet Wipe Motor Slow Speed .A motor on other machines OK, in this machine is slow, occasionally does not turn the phenomenon, power off and then plugged back into the turn again.

1015953 Board PC REAR CONTROL is broken . Can be purchased from SMTCOMPONENTS CO., LIMITED .

58.Where can I buy high quality Mpm Printer foil board clamp 1016013-04 and 1016014-04 ?

SMTCOMPONENTS CO., LIMITED is specialized in selling SMT Parts , where you can buy high quality products . MPM Printer Spare Parts has been supplying to customers all over the world for a long time and all of them have received good comments from customers . You can contact this e-mail address for any information about SMT parts : will@smtcomponents.com

59.MPM Printer Momentum wipes web without spraying alcohol .

If the function is open: 1. check whether the water inlet circuit is clogged 2. pumping motor 1016503 is normal 3. wipe test sticky water motor 1015137 volume speed is normal, too slow cleaning is not brought up or bad motor . 1015802 ITW EAE 2001724 MOTOR,PAPER WINDER .