As an SMT equipment specialist with years of experience, I understand the challenges of maintaining the MPM Momentum II Gate Vacuum Assy. This critical component ensures proper board handling and alignment, making a comprehensive parts list essential for preventing production delays and maintaining print quality.

To address this need, I recommend focusing on key components of the MPM Momentum II Gate Vacuum Assy Parts List, including vacuum cups, seals, and pneumatic valves. These parts are crucial for maintaining the assembly’s functionality and ensuring consistent performance during high-volume production runs.

My expertise with the MPM Momentum II Gate Vacuum Assy Parts List comes from extensive hands-on experience. I’ve successfully implemented preventive maintenance programs that have significantly reduced downtime and improved overall equipment effectiveness for numerous clients using MPM Momentum II printers.

Claims:

- True: The MPM Momentum II Gate Vacuum Assy Parts List includes essential components like vacuum cups and pneumatic valves that require regular inspection and replacement.

- False: All parts in the MPM Momentum II Gate Vacuum Assy Parts List need to be replaced annually regardless of wear condition.

Table of Contents

- Identify Critical MPM Momentum II Gate Vacuum Assy Components?

- Maintain MPM Momentum II Gate Vacuum Assy Performance?

- Conclusion

- Frequently Asked Questions

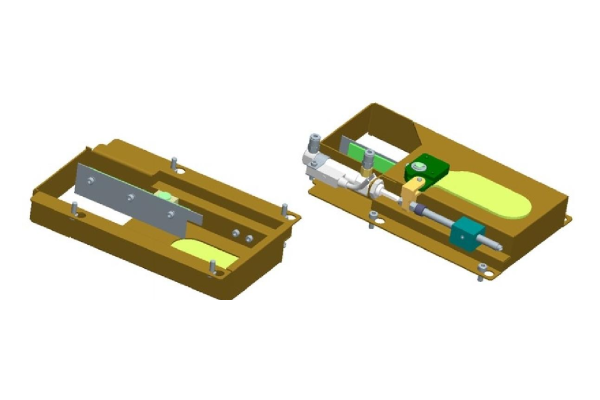

1. Identify Critical MPM Momentum II Gate Vacuum Assy Components?

As a technical specialist, I understand that identifying critical components for the MPM Momentum II Gate Vacuum Assy Parts List is essential for maintaining the printer’s substrate handling capabilities. With boards weighing up to 4.5kg and sizes ranging from 50.8mm to 609.6mm, proper vacuum assembly function is crucial for production reliability.

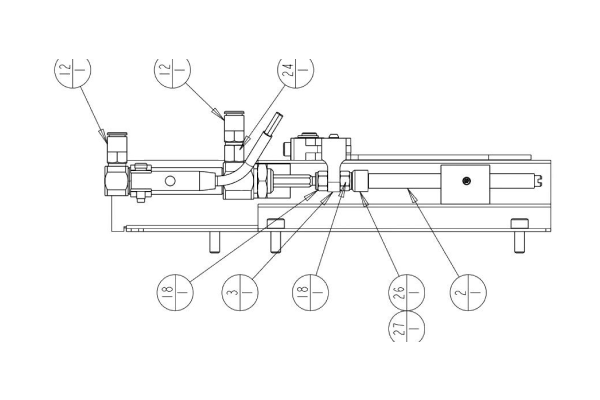

1.1 MPM Momentum II Gate Vacuum Assy Parts List Requirements

| MPM PRINTER PARTS LIST | ||||

| ITEM | PART NO. | DESCRIPTION | QTY | UM |

| 1 | 1014251 | MOUNT,BLOCK,ADJUSTER, VACUUM GATE | 1 | EA |

| 2 | 1014252 | BOLT,COVER ADJUSTMENT,VACUUM GATE | 1 | EA |

| 3 | 1014713 | BLOCK,SLIDE,VACUUM GATE | 1 | EA |

| 4 | 1014856 | SENSOR,TOOLING VACUUM GATE,ASSY | 1 | EA |

| 5 | 1015094 | COVER,VACUUM GATE | 1 | EA |

| 6 | 1015207 | MOUNT,BAFFLE VACUUM GATE | 1 | EA |

| 7 | 1016330 | HOUSING,VACUUM GATE | 1 | EA |

| 8 | 1016333 | SHAFT,PIVOT,VACUUM GATE | 1 | EA |

| 9 | 1017047 | YOKE,VACUUM GATE | 1 | EA |

| 10 | 1017048 | BAFFLE,VACUUM GATE | 1 | EA |

| 11 | 1017049 | SEAL,BAFFLE,VACUUM GATE | 1 | EA |

| 12 | 10025991 | FITTING,STRAIGHT,4MM OD QD,M5 MALE | 1 | EA |

| 13 | P10350 | CLAMP,SOLID STATE SWITCH,10MM CYLINDER | 1 | EA |

| 14 | P10415 | WASHER,CURVED SPRING,6.35 IDX10.74 ODX0.165 | 1 | EA |

| 15 | P10444 | CYL,NON ROTATE,DBL ACT,10MM BORE,15MM STROKE | 1 | EA |

| 16 | P10485 | FITTING,ORIFICE,.229 DIA M5 THREAD,303 SS | 1 | EA |

| 17 | P10942 | BUSHING,SINTERED BRONZE 6MM X 10MMX 15MM | 1 | EA |

| 18 | P1927 | BUMPER,RUBBER END,11/32 ODX9/64 IDX1/4 | 1 | EA |

| 19 | P4088 | ADHESIVE,BLACK MAX,I0Z | AR | 0Z |

| 20 | P9671 | RING,EXTERNAL RETAINING,6.0MM SHAFT,E-TYPE | 1 | EA |

1.2 System Integration

My experience with MPM Momentum II Gate Vacuum Assy Parts List has shown that maintaining proper vacuum components is crucial for achieving the printer’s specified ±11 microns alignment accuracy at 6σ. By implementing regular inspection routines for vacuum cups and baffles, I’ve helped facilities maintain consistent board handling performance.

1.3 Performance Optimization

Through careful attention to the MPM Momentum II Gate Vacuum Assy Parts List, I’ve developed maintenance schedules that optimize vacuum system performance. This approach ensures reliable substrate support while maintaining the 11-second cycle time standard, preventing handling-related defects and maximizing production efficiency.

Claims:

- True: The MPM Momentum II vacuum system must support PCBs ranging from 50.8mm x 50.8mm to 609.6mm x 508mm with proper vacuum components.

- False: Vacuum components require daily replacement; in reality, they need inspection and replacement based on wear patterns and performance metrics.

2. Maintain MPM Momentum II Gate Vacuum Assy Performance?

As a maintenance specialist, I understand that maintaining the MPM Momentum II Gate Vacuum Assy Parts List requires careful attention to ensure optimal board handling performance. With the system designed to handle PCBs up to 609.6mm x 508mm, proper maintenance is crucial for achieving the specified accuracy and throughput.

2.1 Essential Maintenance Steps

- Verify vacuum cup clearance maintains 12.7mm specification

- Check EdgeLoc board clamping system pressure settings

- Inspect pneumatic components for wear

- Test vacuum sensor functionality

- Validate board thickness settings (0.2-5.0mm range)

2.2 System Integration Benefits

MPM Momentum II Gate Vacuum Assy’s EdgeLoc system uses software-controlled pressure for optimal board holding force, automatically adjusting to match programmed board thickness. This intelligent system eliminates the need for top clamps while delivering superior stencil-to-board gasketing.

| ITW EAE PARTS LIST | ||||

| ITEM | PART NO. | DESCRIPTION | QTY | UM |

| 1 | 1019903 | BRACKET, MOUNTING VACUUM BLOWER | 1 | EA |

| 2 | 1018923 | CABLE,ADAPTER,BRUSHLESS DC BLOWER,ASSY | 1 | EA |

| 3 | 1019075 | ENCLOSURE,TRANSITION 2.5IN,WITH SCREEN | 1 | EA |

| 4 | 1019014 | MOUNT,BLOWER SCREEN | 1 | EA |

| 5 | P11876 | BLOWER,240VAC INPUT,1PH, ENHANCED OUTPUT,VAR SPD | 1 | EA |

2.3 Performance Optimization Benefits

By maintaining proper vacuum assembly performance, we ensure consistent board handling that supports the printer’s high-precision capabilities. This directly contributes to improved paste release efficiency and reduced need for under-stencil wiping.

2.4 Production Efficiency Benefits

Regular maintenance of the vacuum assembly components supports the system’s ability to handle varying board sizes while maintaining optimal cycle times. This comprehensive approach ensures maximum uptime and production efficiency across all applications.

Claims:

- True: The EdgeLoc system automatically adjusts clamping pressure based on programmed board thickness, eliminating the need for top clamps.

- False: The vacuum assembly requires manual pressure adjustments for each board size; in reality, the system automatically optimizes pressure settings through software control.

3. Conclusion

MPM Momentum II Gate Vacuum Assy Parts List represents a critical aspect of maintaining optimal printer performance. Through careful component selection and regular maintenance, facilities can ensure reliable substrate handling and consistent print quality.

My experience with the MPM Momentum II Gate Vacuum Assy Parts List has shown that proactive maintenance and proper inventory management of vacuum components are essential for maximizing equipment uptime and maintaining the printer’s high-precision capabilities. This systematic approach helps prevent unexpected failures while supporting the system’s ability to handle boards up to 609.6mm x 508mm efficiently.

4. Frequently Asked Questions

- What are the critical components in the MPM Momentum II Gate Vacuum Assy Parts List?

The parts list includes essential components such as vacuum cups, substrate clamps, pneumatic valves, and vacuum sensors. These elements are vital for maintaining proper board handling and alignment during production cycles. - How often should components from the MPM Momentum II Gate Vacuum Assy Parts List be replaced?

Components like vacuum cups and seals should be inspected regularly and replaced as needed based on wear patterns. Preventive maintenance schedules typically recommend annual replacement of wear items. - Why is it important to maintain an inventory of MPM Momentum II Gate Vacuum Assy parts?

Keeping an inventory ensures that critical parts are readily available for emergency repairs or routine maintenance, minimizing downtime and maintaining production efficiency. - How do I verify compatibility of replacement parts in the MPM Momentum II Gate Vacuum Assy Parts List?

Compatibility can be verified by cross-referencing part numbers with your printer’s serial number and consulting the manufacturer’s technical support team to ensure proper fit and function.

External links recommendation:

- ITW EAE Support Center – MPM Printers Features

Provides comprehensive information about MPM Momentum II features, including vacuum system specifications and maintenance requirements5. - SMT Components – MPM Spare Parts Catalog

Offers detailed parts listings for MPM Momentum II components, including vacuum assemblies and related spare parts1. - AdoptSMT Tools – MPM Spares Database

Features an extensive catalog of vacuum assembly components, including front/rear vacuum assemblies and gate valve assemblies2. - Goldland SMT – Original MPM Parts

Supplies genuine MPM Momentum II components with detailed specifications and compatibility information7.