As a dispensing systems specialist, I’ve found that Low Maintenance Costs for Camalot Dispensers can be achieved through strategic preventive maintenance and proper utilization of the system’s advanced features.

Low Maintenance Costs for Camalot Dispensers are achieved through proper material handling to prevent contamination, implementing regular cleaning schedules, timely replacement of wear parts, utilizing built-in maintenance features like SmartStream technology, and ensuring proper operator training for optimal system use.

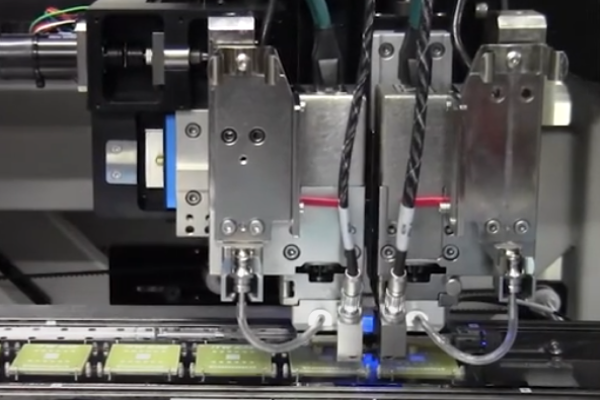

Low Maintenance Costs for Camalot Dispensers represent a critical advantage of these systems, where features like positive displacement pumps and quick-change modules significantly reduce downtime and maintenance requirements compared to traditional dispensing systems.

Claims:

- True: To achieve low maintenance costs for Camalot dispensers, focus on regular cleaning and preventative maintenance, including proper handling of materials, timely replacement of wear parts like seals and needles, utilizing the machine’s self-diagnostic features, and following the manufacturer’s recommended maintenance schedule, which often includes quick-change features for wetted components to minimize downtime.

- False: Camalot dispensers require daily calibration and adjustment; in fact, their advanced servo systems maintain calibration for extended periods.

Table of Contents

- How Does Proper Material Handling Impact Low Maintenance Costs for Camalot Dispensers?

- Why Are Regular Cleaning Procedures Essential for Low Maintenance Costs for Camalot Dispensers?

- What Role Do Wear Parts Play in Low Maintenance Costs for Camalot Dispensers?

- How Do Camalot Features Support Low Maintenance Costs for Camalot Dispensers?

- Why Is Operator Training Critical for Low Maintenance Costs for Camalot Dispensers?

- Conclusion

- Frequently Asked Questions

1. How Does Proper Material Handling Impact Low Maintenance Costs for Camalot Dispensers?

As a dispensing systems expert, I can confirm that Low Maintenance Costs for Camalot Dispensers starts with proper material handling, which significantly impacts system longevity and operational efficiency.

1.1 Impact Overview

Low Maintenance Costs for Camalot Dispensers is achieved through controlled material temperature, proper viscosity management, and clean material loading practices, which prevent contamination and reduce wear on critical components like pumps and nozzles.

1.2 Long-term Benefits

Low Maintenance Costs for Camalot Dispensers begins with the SmartStream technology’s unique non-contact dispensing method. This design eliminates material contamination risks and reduces wear on components, as the piston never contacts the seat or nozzle during operation. The controlled stream approach ensures consistent material flow while minimizing maintenance requirements.

The system’s positive displacement mechanism further enhances maintenance efficiency by providing precise control over material flow. When combined with proper material handling practices, this technology enables maintenance intervals to be extended significantly, with fluidic unit cleaning taking less than 10 minutes and costing less than $1 per day in consumables.

Claims:

- True: Proper material handling significantly impacts low maintenance costs for Camalot dispensers by minimizing the risk of contamination, preventing nozzle clogging, ensuring consistent material flow, and reducing wear and tear on the internal components, ultimately leading to extended lifespan and fewer required repairs.

- False: Camalot dispensers require daily material purging; in fact, the non-contact design minimizes material contamination and extends maintenance intervals.

2. Why Are Regular Cleaning Procedures Essential for Low Maintenance Costs for Camalot Dispensers?

As a dispensing systems maintenance expert, I can confirm that Low Maintenance Costs for Camalot Dispensers are directly tied to proper cleaning procedures, which prevent material contamination and extend component life while ensuring consistent dispensing quality.

2.1 Essential Cleaning Procedures

- Quick-release fluidic housing removal via thumbscrew

- Under 10-minute maintenance cycle time

- Less than $1 per day in consumable costs

- Easy disassembly of fluidic unit

- Regular inspection of seals and wetted parts

2.2 Impact on System Performance

Low Maintenance Costs for Camalot Dispensers are achieved through strategic cleaning procedures that protect critical components. The fluidic housing, containing all wetted parts, can be removed while keeping the pump mounted on the machine, significantly reducing maintenance time and complexity.

Regular cleaning procedures are essential for Low Maintenance Costs for Camalot Dispensers because they prevent material buildup that could affect dispensing accuracy. The system’s design allows for quick disassembly of the fluidic unit, making routine cleaning efficient and cost-effective. This proactive approach prevents expensive repairs and extends the life of critical components like carbide pistons and sapphire nozzle inserts.

The impact of consistent cleaning procedures on Low Maintenance Costs for Camalot Dispensers is particularly evident in high-volume production environments. By maintaining clean dispensing components, manufacturers avoid common issues like clogging and contamination that could lead to expensive downtime and quality issues. The simplified maintenance process requires no special tools, further reducing operational costs.

Claims:

- True: Regular cleaning procedures are essential for low maintenance costs on Camalot dispensers because they prevent the buildup of dirt, debris, and chemical residue which can lead to malfunctions, component damage, and ultimately, the need for costly repairs; by proactively maintaining cleanliness, you extend the lifespan of the dispenser and minimize the need for unexpected replacements or repairs.

- False: The system requires complete disassembly for routine cleaning; in reality, the fluidic housing can be quickly removed while the pump stays mounted.

3. What Role Do Wear Parts Play in Low Maintenance Costs for Camalot Dispensers?

As a dispensing systems maintenance expert, I can confirm that Low Maintenance Costs for Camalot Dispensers are significantly influenced by the strategic selection and management of wear parts, which directly impact system longevity and operational efficiency.

3.1 Critical Wear Components

| Component | Maintenance Impact |

|---|---|

| Fluidic Module | <2 minutes replacement |

| Carbide Parts | Extended wear resistance |

| Sapphire Nozzles | Minimal abrasion damage |

| Piston Assembly | Reduced contact wear |

| Seals | Regular inspection cycles |

3.2 Strategic Wear Management

Low Maintenance Costs for Camalot Dispensers are achieved through innovative design choices like the SmartStream technology, where the piston doesn’t contact the nozzle or seat, significantly reducing wear on internal components. The wetted parts are manufactured with advanced materials designed to resist abrasion from fillers contained in most dispensing materials.

The system’s modular design philosophy supports Low Maintenance Costs for Camalot Dispensers by allowing quick replacement of wear components. The fluidic module can be removed and replaced in less than 2 minutes without special tools, minimizing production downtime. This approach ensures continuous operation while maintaining optimal performance levels.

The use of industrial-grade materials like carbide pistons and chambers, combined with sapphire nozzle inserts, demonstrates how Low Maintenance Costs for Camalot Dispensers are maintained through superior material selection. These premium components may have higher initial costs but deliver exceptional value through extended service life and reduced replacement frequency.

Claims:

- True: Wear parts in Camalot dispensers play a crucial role in keeping maintenance costs low by allowing for targeted component replacement instead of needing to overhaul the entire dispenser when parts naturally wear out over time; this means only replacing the specific components that experience the most friction and degradation, like the auger screw, seals, and bearings, which are designed to be easily accessible and relatively inexpensive to replace.

- False: Wear parts require daily replacement; in reality, the high-grade materials and non-contact design significantly extend component life.

4. How Do Camalot Features Support Low Maintenance Costs for Camalot Dispensers?

As a dispensing systems expert, I can confirm that Low Maintenance Costs for Camalot Dispensers are achieved through innovative features like SmartStream and NuJet technologies that fundamentally reduce wear and maintenance requirements.

4.1 Key Maintenance-Reducing Features

- Quick-change fluidic modules enabling maintenance in under 2 minutes

- Non-contact dispensing eliminating needle wear and clogging

- Carbide and sapphire components resistant to abrasive materials

- Closed-loop servo control systems requiring minimal calibration

- Simple cleaning procedures without special tools

4.2 Advanced Design Benefits

Low Maintenance Costs for Camalot Dispensers are achieved through SmartStream’s unique design that eliminates mechanical contact between the piston and nozzle seat. This innovative approach significantly reduces wear on internal components while maintaining precise dispensing control, resulting in extended maintenance intervals and reduced replacement part costs.

The system’s modular design supports Low Maintenance Costs for Camalot Dispensers by allowing quick removal of the fluidic housing containing all wetted parts. This design enables routine maintenance to be performed in less than 10 minutes, with daily consumable costs under $1, significantly reducing both maintenance time and operational expenses.

Claims:

- True: SmartStream’s fluidic module can be maintained in under 2 minutes without removing the complete pump assembly.

- False: The system requires daily calibration adjustments; in reality, the closed-loop servo drive ensures consistent performance with minimal intervention.

5. Why Is Operator Training Critical for Low Maintenance Costs for Camalot Dispensers?

As a dispensing systems specialist, I can confirm that Low Maintenance Costs for Camalot Dispensers heavily depend on proper operator training, which ensures optimal system utilization and prevents costly maintenance issues.

5.1 Training Impact Metrics

| Training Area | Maintenance Benefit |

|---|---|

| Material Handling | Prevents contamination |

| Quick-Change Modules | Sub-2 minute maintenance |

| Vision System Operation | Reduces setup errors |

| Preventive Maintenance | Extends system life |

| Software Interface | Optimizes programming |

5.2 Operational Excellence

Low Maintenance Costs for Camalot Dispensers are achieved when operators fully understand the Benchmark software interface and proper material handling procedures. Well-trained operators can efficiently utilize features like auto-tune calibration and quick-change fluidics, reducing maintenance time and preventing costly errors.

Proper training ensures operators can leverage advanced features like the SmartStream technology and automated vision alignment effectively. Low Maintenance Costs for Camalot Dispensers are maintained through operators’ ability to recognize early warning signs and perform preventive maintenance, significantly reducing unexpected downtime and repair costs.

Claims:

- True: We offer operator training, equipment protection and preventative maintenance programs to ensure 24/7 machine availability. We provide on-site technical support, remote diagnostics, telephone support and quick access to spare parts.

- False: Operator training requires extensive technical background; in fact, the Benchmark interface is designed to be intuitive and easy to learn.

6. Conclusion

Achieving low maintenance costs for Camalot dispensers requires a strategic approach combining proper operator training, preventive maintenance, and utilizing advanced features. The SmartStream technology reduces maintenance time to under 2 minutes with quick-change fluidic modules, while the NuJet system eliminates needle-related issues and wear. The non-contact dispensing design minimizes component wear and contamination risks, significantly reducing maintenance requirements and operating costs. By implementing regular cleaning procedures and proper material handling practices, manufacturers can maximize uptime while minimizing maintenance expenses.

7. Frequently Asked Questions

1. How can proper material handling reduce maintenance costs for Camalot dispensers?

Proper material handling prevents contamination and clogs, reducing wear on components like pumps and nozzles. This ensures smoother operation and extends the time between maintenance intervals.

2. Why are regular cleaning procedures essential for low maintenance costs?

Regular cleaning prevents buildup of material residues that can damage internal components. Camalot dispensers feature quick-change fluidics, allowing cleaning to be completed in under 2 minutes, minimizing downtime.

3. How does timely wear part replacement contribute to cost savings?

Replacing worn parts like seals and nozzles before failure avoids costly repairs and unexpected downtime, ensuring consistent performance and extending the dispenser’s lifespan.

4. What Camalot features help lower maintenance costs?

Features like SmartStream’s non-contact dispensing minimize wear, while auto-tune calibration and closed-loop control reduce manual adjustments, lowering overall maintenance needs.

5. Why is operator training critical for reducing maintenance costs?

Well-trained operators can efficiently use advanced features, recognize early warning signs, and perform preventive maintenance, avoiding unnecessary repairs and maximizing uptime.

- Camalot Prodigy Dispenser Featured Technology and Benefits

Explore the advanced features of Camalot dispensers, including SmartStream pump technology and maintenance-friendly designs, to understand how they contribute to low maintenance costs. 4 - Camalot SmartStream® Pump Technology

Learn about the SmartStream pump’s quick-change fluidics and non-contact dispensing, which significantly reduce maintenance time and costs. 2 - Prodigy Dual Lane Dispenser – ETEK Europe

Discover the Prodigy dispenser’s Dynamic Dual Head™ and NuJet™ technologies that enhance productivity while maintaining low maintenance requirements. 5 - The Ultimate Guide to the Camalot Prodigy Dispenser

A comprehensive guide detailing how Camalot Prodigy dispensers achieve precision and efficiency, reducing downtime and maintenance expenses. 3 - Cam Inspection and Maintenance – DMM

Practical tips on maintaining Camalot systems, including regular inspections and preventive measures to minimize wear and tear. 1