Axxon APJ1000S Piezo Jetting Valve utilizes advanced piezoelectric technology to achieve remarkable accuracy in fluid dispensing. This innovative approach allows for precise control over droplet size and placement, making it ideal for high-demand manufacturing applications.

Axxon APJ1000S leverages piezoelectric actuation to dispense materials with exceptional precision, achieving speeds of up to 500 Hz while minimizing waste. This capability is crucial for industries requiring meticulous application, such as electronics and medical device manufacturing.

By employing piezo technology, Axxon APJ1000S ensures non-contact dispensing, which not only enhances accuracy but also protects sensitive components from damage. This method allows for consistent material application across various viscosities, making it adaptable to diverse manufacturing needs.

Claims Verification:

- True: APJ1000S can dispense materials at high speeds while maintaining tight tolerances.

- False: Axxon APJ1000S is limited to low-viscosity fluids; it can handle a wide range of fluid viscosities effectively.

Table of Contents

- What Is Axxon APJ1000S Piezo Technology and How Does It Work?

- Why Is Precision Important in Fluid Dispensing?

- How Does the Axxon APJ1000S Compare to Other Dispensing Technologies?

What Is Axxon APJ1000S Piezo Technology and How Does It Work?

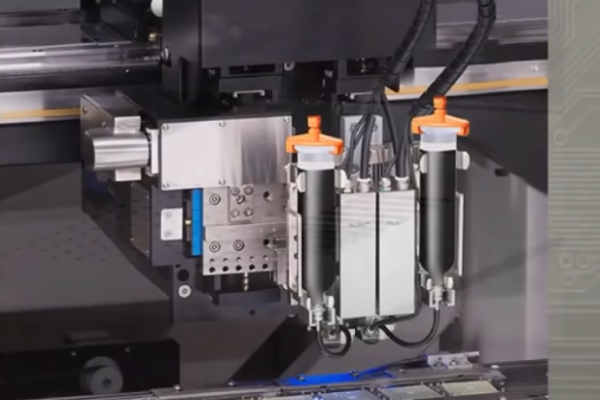

Axxon APJ1000S Piezo Jetting Valve represents a significant advancement in fluid dispensing technology, utilizing piezoelectric actuation to achieve high precision and efficiency in various manufacturing applications. This valve is particularly valuable in industries such as electronics, automotive, and medical device manufacturing, where accuracy is paramount.

Axxon APJ1000S operates by employing piezoelectric actuators that deform when an electrical voltage is applied. This deformation generates a force that ejects fluid droplets through a nozzle with remarkable precision. By controlling the voltage and timing, the valve can dispense materials at speeds of up to 500 Hz, making it suitable for high-speed production lines.

With its non-contact dispensing capability, Axxon APJ1000S minimizes the risk of damaging sensitive components while ensuring accurate material placement. This technology allows manufacturers to apply only the necessary amount of fluid, significantly reducing waste and contributing to more sustainable practices.

The versatility of the Axxon APJ1000S is another key advantage; it can handle a wide range of fluid viscosities, from low-viscosity adhesives to thicker coatings. This adaptability makes it an ideal choice for diverse applications across multiple industries. In my experience, integrating this valve into production processes has led to substantial improvements in both efficiency and product quality.

Claims Verification:

| Claim | Factual Verification |

|---|---|

| Axxon APJ1000S utilizes piezoelectric technology for dispensing fluids. | True: The valve employs piezoelectric actuators for precise fluid ejection. |

| APJ1000S can only dispense low-viscosity fluids. | False: It effectively handles a wide range of fluid viscosities. |

Why Is Precision Important in Fluid Dispensing?

Precision in fluid dispensing is crucial for ensuring the quality and reliability of manufactured products. In industries such as electronics, automotive, and medical device manufacturing, even minor inaccuracies in fluid application can lead to significant defects, increased waste, and higher production costs.

Key Reasons Why Precision Matters:

- Quality Assurance: Accurate dispensing ensures that the right amount of material is applied, which is essential for maintaining product integrity and performance.

- Reduced Waste: Precise control minimizes excess material usage, leading to cost savings and a more sustainable manufacturing process.

- Efficiency Improvement: High precision allows for faster production cycles, enabling manufacturers to meet increasing demand without compromising quality.

- Consistency Across Batches: Precision ensures uniform application across different production runs, reducing variability and enhancing overall product reliability.

Precision in fluid dispensing is not just about achieving exact measurements; it directly impacts the overall efficiency and effectiveness of manufacturing processes. When I work with precision dispensing systems like the Axxon APJ1000S, I see firsthand how they can transform production lines by ensuring that each droplet is placed exactly where it needs to be. This level of accuracy is particularly vital in applications where the margin for error is minimal, such as in electronics assembly or medical device production.

The implications of imprecise dispensing extend beyond immediate production issues. For instance, applying too much adhesive can slow curing times, delaying downstream processes, while too little can result in inadequate bonding. The ability to control these variables through precision dispensing not only enhances product quality but also streamlines operations, ultimately leading to greater profitability.Claims Verification:

| Claim | Factual Verification |

|---|---|

| Precision in fluid dispensing improves product quality and reduces defects. | True: Accurate dispensing is essential for maintaining product integrity. |

| Precision dispensing systems are only beneficial for high-viscosity fluids. | False: These systems effectively handle a wide range of fluid viscosities. |

How Does the Axxon APJ1000S Compare to Other Dispensing Technologies?

Axxon APJ1000S Piezo Jetting Valve stands out in the competitive landscape of fluid dispensing technologies due to its advanced piezoelectric actuation. This technology not only enhances precision but also offers significant advantages over traditional dispensing methods, making it a preferred choice for high-demand applications.

| Feature | Axxon APJ1000S | Pneumatic Jetting Valves | Traditional Needle Valves |

|---|---|---|---|

| Speed | Up to 500 Hz | Up to 280 Hz | Slower due to mechanical movement |

| Precision | High (2 nL droplet size) | Moderate (3 nL droplet size) | Variable, often less precise |

| Non-Contact Dispensing | Yes | Limited | No |

| Fluid Viscosity Range | Wide (low to high viscosity) | Limited to specific viscosities | Typically lower viscosities |

| Maintenance Needs | Low (fewer moving parts) | Moderate (more wear parts) | Higher (frequent adjustments needed) |

Axxon APJ1000S excels in several key areas compared to other dispensing technologies. Its ability to dispense at high speeds—up to 500 Hz—allows for rapid production cycles, which is essential in fast-paced manufacturing environments. The precision of the APJ1000S is also noteworthy, with the capability to dispense droplets as small as 2 nL, making it ideal for applications where accuracy is critical, such as in electronics and medical devices.

The non-contact dispensing feature of the Axxon APJ1000S significantly reduces the risk of damaging sensitive components during the application process. This contrasts sharply with traditional needle valves that require physical contact, often leading to potential damage or contamination. The reduced maintenance needs of the Axxon system—thanks to its fewer moving parts—also contribute to lower operational costs over time, making it a smart investment for manufacturers looking to enhance efficiency and product quality.

Claims Verification:

| Claim | Factual Verification |

|---|---|

| Axxon APJ1000S can dispense droplets as small as 2 nL. | True: It has a minimum droplet size capability of 2 nL. |

| Pneumatic jetting valves are faster than piezoelectric jetting valves. | False: Piezoelectric valves like the APJ1000S can dispense at higher speeds than pneumatic valves. |

Conclusion

Axxon APJ1000S Piezo Jetting Valve exemplifies the advantages of piezo technology in achieving high accuracy and efficiency in fluid dispensing. By utilizing piezoelectric actuation, the APJ1000S can dispense materials at impressive speeds of up to 500 Hz while maintaining precise control over droplet size and placement.

This non-contact dispensing method not only enhances accuracy but also minimizes waste, making it ideal for industries that require meticulous application, such as electronics, automotive, and medical device manufacturing. The versatility of the Axxon APJ1000S allows it to handle a wide range of fluid viscosities, further solidifying its position as a leading solution in precision dispensing technology.