As a wave soldering expert, I can confirm that Vitronics Soltec Delta X Spare Parts are crucial for maintaining optimal machine performance and preventing costly downtime. Understanding these components is essential as they directly impact your wave soldering quality, machine reliability, and production efficiency.

Vitronics Soltec Delta X Spare Parts include critical components such as titanium solder pot parts, heavy-duty titanium fingers, conveyor system components, fluxing unit parts, and preheater elements. These parts are categorized by their function and replacement frequency, ensuring proper maintenance and minimal interruption to production schedules.

Table of Contents

- What Critical Components Are Included in Vitronics Soltec Delta X Spare Parts?

- Conclusion

- Frequently Asked Questions

1. What Critical Components Are Included in Vitronics Soltec Delta X Spare Parts?

As a wave soldering specialist, I can confirm that Vitronics Soltec Delta X Spare Parts include critical components essential for maintaining optimal machine performance. These parts are categorized based on their function and replacement frequency to ensure continuous operation in high-volume production environments.

1.1 Vitronics Soltec Delta X Spare Parts List

| Part Number | Description |

| 7-38377 | RING O ID 20*3 ERIKS VI70 SHORE A |

| 7-38748 | SPRAY NOZZLE FLUID CAP FC7 SPRAYBEST SS |

| 7-38850 | AIR CAP ACN |

| 7-38851 | CAP NUT |

| 7-40877 | REPLACEABLE TIP E |

| 7-40878 | SEAL KIT |

| 7-C00214 | BELT TIMIMG 255L050 |

| 7-C00503 | HOUSE BEARING INA RSHE 20 |

| 7-C00542 | LINKTECH 20ACV-SV1-02 18″NPT |

| 7-C00543 | LINKTECH 20ACV-SB1-04BSPT |

| 7-C00544 | LINKTECH 20ACV-PV4-02 18″NPT |

| 7-C450105 | RING D34 ID20.2 L10 ST |

| 7-C450403 | TESTING GLASS |

| 7-C450602 | GRAPHITE RING D34 ID22 L12 |

| 7-210752 | FILTER 275*588*12.5 SS |

| 7-47235 | SOLID STATE CARLO GAVAZZI RGC2A60D25KKE |

| 7-C80743 | SENSOR INDUCTIVE BAUMERIFRM 08P3707+CONNECTOR |

| 7-C97469 | MICRO-SWITCH HONEYWELL V15H22-CZ100A05 RS 515-76 |

| 7-C97549 | THERMOSTAT PT100 SOLDERPOT LEAD-FREE COMP TI |

| 7-C97586 | EL. IGNORE BACKGROUND SICK GTB6-P4212 1052442 |

| 7-C99136 | ENCODER SENSOR AUTONICSE40S6-500-3-T-24 5M CAB |

| 7-C99153 | THERMOSTAT PT100 PRE HEATER |

| 7-C97332 | THERMO SENSOR PT100 FC.315546C |

| 7-311331 | SPRAY NOZZLE FC7(XAEF100E) |

| 7-C98976 | SENSOR SICK IQ08-02BPSKT0S 1055494 |

| 7-33677 | BEARING BALL D12*28*8 SKF6001-2Z |

| 7-C01051 | BELT POLY-V DIN7867 6PJL965 |

| 7-44435 | BELT TIMING HTD-1420-5M-15 |

| 7-640.6057 | BEARING BALL D12*28*08SKF6001-2RSH |

| 7-39048 | BELT POLY-V DIN 7867 6PJ1168 |

| 7-431358 | PCB SUPPORT WIRE 1.5 L=3,5 MTR |

| 7-C450001 | FINGER V-SHAPE (HEAVY DUTY) |

| 7-C450126 | FINGER L-SHAPE (HEAVY DUTY) |

1.2 Critical Components

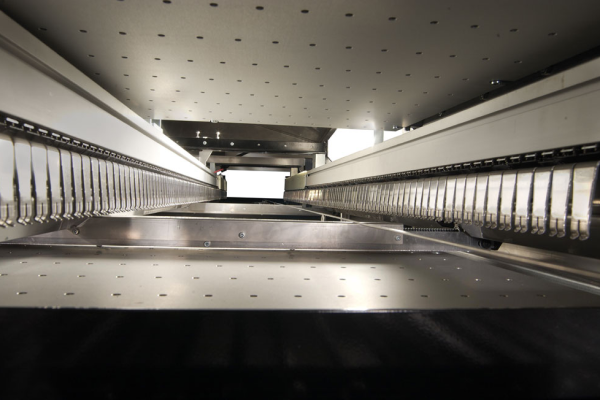

- Conveyor System with parallel rails and chains

- Solderpot with titanium components

- Heavy Duty Titanium Fingers for reduced replacement

- Base Wire Support assemblies

- Nozzle Spray Fluxer components

1.3 System Maintenance Strategy

Vitronics Soltec Delta X Spare Parts conveyor system includes multiple lead-screws and mechanical components that ensure parallel rails within 1.0mm tolerance. I recommend regular inspection of these components to maintain precise product positioning.

The titanium solderpot components in Vitronics Soltec Delta X Spare Parts feature a unique dross management design. This system requires periodic maintenance to ensure optimal solder wave formation and consistent soldering quality.

For the heavy-duty titanium fingers, Vitronics Soltec Delta X Spare Parts include flexible chain components that accommodate thermal expansion while preventing board warpage. These components significantly reduce finger replacement frequency compared to standard designs.

The fluxing unit in Vitronics Soltec Delta X Spare Parts includes pressure-controlled components with stepper motors for precise application. I recommend maintaining a stock of critical parts like flux pump gaskets and quick-couple fittings to prevent production interruptions.

The preheater system of Vitronics Soltec Delta X Spare Parts features exchangeable modules including IR calrod and quartz lamps. Regular monitoring of these components ensures consistent preheat profiles and optimal soldering results.

Claims:

- True: The Vitronics Soltec Delta X wave soldering machine has evolved from a long heritage of soldering machines with thousands in production worldwide. With technology driven features developed over generations the Delta X is a reliable, dependable and cost-efficient wave soldering machine.

- False: All spare parts require daily replacement; in fact, many components are designed for extended operation with proper maintenance schedules.

2. Conclusion

Vitronics Soltec Delta X Spare Parts represent a comprehensive system of critical components designed to maintain optimal wave soldering performance. From titanium solder pot components to heavy-duty fingers and conveyor systems, these parts ensure reliable operation and minimal downtime.

The availability of both mechanical and electronic components, including circuit boards and motors, supports the machine’s advanced features while maintaining its impressive throughput capabilities. For optimal maintenance, it’s essential to work with authorized suppliers and maintain proper documentation of your machine’s serial number when ordering replacement parts.

3. Frequently Asked Questions

1. What are the critical components included in the Delta X spare parts list?

The key components include titanium solder pot parts, heavy-duty titanium fingers, conveyor system components with parallel rails, fluxer components with pressure-controlled supply, and preheater elements including IR calrod and quartz lamps12.

2. How does the conveyor system ensure reliable operation?

The conveyor system uses multiple lead-screws that are mechanically driven to ensure parallel rails within 1.0mm tolerance, while the solderpot blocking system guarantees repeatable positioning for consistent soldering quality2.

3. What makes the heavy-duty titanium fingers important?

The HD titanium fingers dramatically reduce replacement frequency and feature a flexible chain design that allows for smooth interface while preventing board warpage due to thermal expansion2.

4. What are the key fluxer components that need maintenance?

The fluxer unit includes pressure-controlled components with stepper motor drive, dual nozzle supply systems, and precision spray nozzles that require regular maintenance to ensure precise, repeatable flux application14.

5. How are the preheater components configured?

The preheater system features exchangeable modules including IR calrod, quartz lamps, and forced convection options. These modules are easily configurable in the software and require periodic maintenance to ensure consistent heating profiles24.

External links recommendation:

- ITW EAE Support Center – Spare Parts Lists

Access comprehensive documentation for Vitronics Soltec machines, including detailed parts lists and identification guides. Technical support team assists with specific part identification when provided with machine serial numbers.

Source: ITW EAE Support - JMW Enterprises – Vitronics Soltec Products

Extensive catalog of genuine parts including motors, transformers, circuit boards, and specialized components for Delta X wave soldering machines.

Source: JMW Enterprises - Allai SMT – Wave Soldering Spare Parts

Complete range of spare parts for Vitronics Soltec wave soldering machines, including Delta series components and titanium fingers.

Source: Allai SMT - SMTnet – Delta X Technical Documentation

Detailed technical information about the Delta X wave soldering machine, including component specifications and maintenance requirements.

Source: SMTnet - ITW EAE Direct Industry – Delta X Catalog

Official product documentation covering machine specifications, components, and recommended spare parts for optimal performance.

Source: ITW EAE