As a maintenance specialist, I can confirm that finding the right MPM Spare Parts for Momentum II Hardstop is crucial for maintaining the precision and reliability of your stencil printer. These parts ensure that the machine operates smoothly, minimizing downtime and maximizing productivity.

To quickly find MPM Spare Parts for Momentum II Hardstop, focus on key components such as the hardstop assembly and related sensors. These parts are essential for maintaining the mechanical integrity of your printer and ensuring consistent performance across all production cycles.

To streamline your spare parts management, I recommend establishing a proactive inventory system that includes both Level 1 wear items and Level 2 critical components. Regularly review your stock levels and reorder points to prevent unexpected downtime and maintain continuous operation.

Claims:

- True: MPM spare parts lists include both Level 1 wear items for regular maintenance and Level 2 critical components to prevent machine downtime.

- False: Hardstop components require complete system shutdown for replacement; in fact, they feature quick-change designs for minimal production interruption.

Table of Contents

- What Critical Components Are Included in MPM Spare Parts for Momentum II Hardstop?

- Conclusion

- Frequently Asked Questions

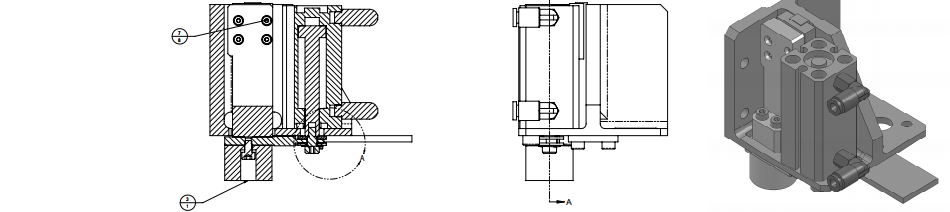

1. What Critical Components Are Included in MPM Spare Parts for Momentum II Hardstop?

As a maintenance specialist with extensive experience, I can confirm that the MPM Spare Parts for Momentum II Hardstop include critical components essential for maintaining the printer’s precision and reliability.

1.1 Mpm Printer Momentum II Hardstop Spare Parts List

| ITW EAE PARTS LIST | ||||

| ITEM | PART NO. | DESCRIPTION | QTY | UM |

| 1 | 1014350 | BRACKET,COIL PICK-UP | 1 | EA |

| 2 | 1014351 | PLATE,CYLINDER,TOOLING | 1 | EA |

| 3 | 1014686 | HARDSTOP,BLANK | 1 | EA |

| 4 | 1014687 | BRACKET,SENSOR MOUNT | 1 | EA |

| 5 | 1014942_ | KIT,CABLE,VISION HARD STOP OPTION | 1 | EA |

| 6 | 1015317 | BRACKET,CYLINDER MOUNTING | 1 | EA |

| 7 | P4086_ | ADHESIVE, THREADLOCK, REMOVABLE, 222, 250ML, PUR | AR | EA |

| 8 | P6792 | FITTING,ELBOW, 4MM OD QD.M5M, PLASTIC | 2 | EA |

| 9 | P9306_ | ADHESIVE,THREADLOCK,HIGH STRENGTH,271 RED | AR | OZ |

| 10 | P10088 | CYLINDER,DBL ACT,12MM | 1 | EA |

| 11 | P10237 | BEARING,LINEAR,7MMX5MM, 1 CAR | 1 | EA |

| 12 | P10245 | SCREW,SHOULDER,3.987MM ODX 4.01MM LG,M3 THREAD | 1 | EA |

| 13 | P10249 | WASHER, CURVED SPRING, 4.32 ID X 9.0 OD X 0.5 THK | 1 | EA |

| 14 | P10773_ | LOCTITE,GEL,2033,MED STRENGTH,35g BOTTLE | AR | OZ |

1.2 Maintenance Strategy

MPM Spare Parts for Momentum II Hardstop system includes crucial components like the hardstop bracket (part number 1014350) and the flag arm hardstop bracket (part number 1014351). These parts are essential for maintaining the mechanical integrity of the printer’s hardstop mechanism, ensuring consistent performance and preventing damage during operation.

To optimize maintenance, I recommend implementing a proactive replacement strategy for MPM Spare Parts for Momentum II Hardstop components. This includes regularly inspecting wear items like bracket and bearing, and scheduling replacements before they fail. Additionally, maintaining an inventory of critical hardstop components ensures quick repairs and minimizes downtime in high-volume production environments.

Claims:

- True: Critical components typically included in MPM spare parts for a Momentum II Hardstop stencil printer would be: linear bearings and any components related to the hardstop mechanism itself, as these are wear items that can impact print quality and machine functionality if not replaced regularly.

- False: Hardstop components require daily replacement; in fact, they are designed for long-term reliability with scheduled maintenance.

2. Conclusion

Managing MPM Spare Parts for Momentum II Hardstop components requires a strategic approach to maintain the printer’s impressive accuracy of ±12.5µm at >2 Cpk (6 sigma). By implementing a proactive inventory system for both Level 1 wear items and Level 2 critical components, manufacturers can prevent unexpected downtime and ensure continuous operation. The system’s plug-and-play architecture, combined with quick-change features, facilitates efficient maintenance while the rigid steel frame construction eliminates vibrations and ensures reliable performance.

3. Frequently Asked Questions

1. What are the key categories of MPM Momentum II spare parts?

The spare parts are divided into Level 1 (wear items for annual maintenance and low-cost critical parts) and Level 2 (comprehensive critical components that could cause machine downtime)2.

2. How do I identify the correct hardstop spare part for my machine?

Contact Technical Support with your machine serial number and provide a picture or description of the part’s location. This ensures accurate part identification for components like the hardstop assembly3.

3. What role do hardstop components play in machine performance?

Hardstop components are crucial for maintaining the printer’s impressive accuracy of ±12.5µm at >2 Cpk (6 sigma) and ensuring consistent board-to-stencil alignment4.

4. How can I minimize downtime when replacing hardstop components?

Maintain an inventory of both Level 1 and Level 2 spare parts, establish clear replacement schedules, and utilize the system’s quick-change features to ensure rapid component replacement without extended production interruptions1.

- ITW EAE Support Center – Momentum II Parts

Access comprehensive documentation for Momentum II components, including hardstop assemblies and precision ball screws that ensure the ±12.5µm accuracy at >2 Cpk (6 sigma).

Source: ITW EAE Support - SMT Components – MPM Printer Parts Guide

Detailed catalog featuring Momentum II mechanical components, including linear guides, rigid steel frame parts, and hardstop assemblies essential for maintaining precision alignment.

Source: SMT Components - Speedline Technologies Parts Database

Complete database of genuine MPM parts, including Level 1 and Level 2 components for the Momentum II hardstop system and related assemblies.

Source: Speedline Technologies