More efficient solder paste printing process

ASMPT, the market pioneer and innovation leader in SMT production technology, has added two new features to its proven DEK Printer platform: automatic solder paste transfer and simplified squeegee replacement.

The ASMPT DEK Printer, with its broad product portfolio, covers virtually every aspect of the SMT production process, while continuing to drive automation and streamline operations. Rick Goldsmith, Director of Product Management at ASMPT, explains, “The solder paste printing process is the most error-prone part of SMT production, and many of these steps still rely on manual labor. still rely on manual labor. However, as it becomes more difficult to recruit qualified operators, our customers are increasingly looking for innovative solutions that can reduce labor and material costs while effectively minimizing error rates.” .

Solder Paste Transfer

When it was time to change the settings on the ASMPT DEK Printer, the paste from the old stencil needed to be transferred to the new stencil, Goldsmith explains: “Previously, this process was done manually using a trowel. This method often resulted in some of the paste not transferring completely, leaving some on the old stencil. In addition, the solder paste could become contaminated or be transferred to the wrong place, which could lead to short circuits and other problems.” .

This process is now simplified with the new solder paste transfer device offered by DEK TQ. As long as the process parameters are set to allow it, the solder paste is automatically transferred whenever the stencil is changed. To do this, a squeegee pushes the paste to the transfer device, which then applies the paste to the new stencil. The system then uses the stencil bottom cleaning device to clean the paste residue.

Goldsmith emphasizes, “This fully automated solder paste transfer system eases the workload of already scarce operators. It is faster, more accurate and more efficient than manual operations. Whereas traditional manual operations often leave up to 10% of the solder paste on the stencil, our automatic solder paste transfer system reduces this figure by 5%. The system provides significant savings in solder paste costs, thereby reducing the production cost per PCB.” The new solder paste transfer system can be easily installed on all series of DEK TQ solder paste printers.

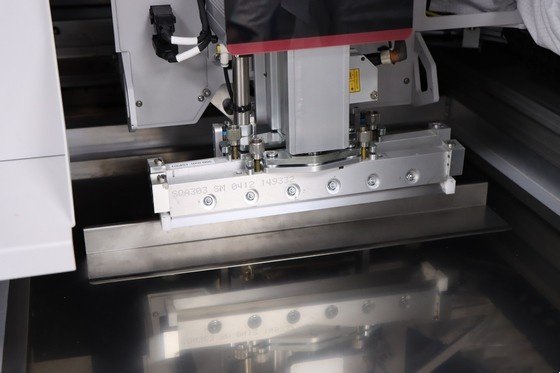

Quick Change Squeegee

The ASMPT DEK Printer has also improved the squeegee replacement process for solder paste printers, Goldsmith explains: “Previously, the squeegee was held in place with two thumbscrews, and in order to replace the squeegee the operator would need to loosen and then re-tighten the pair of screws, which was a very time-consuming process that often led to problems. For example, some operators would tighten the screws so much that a subsequent operator would not be able to loosen them. The time factor is also important, and it is not uncommon to perform more than 20 squeegee changes in a single day.”

Thanks to the innovative design of the new holder, the squeegee is automatically unlocked when it needs to be removed from the machine, greatly simplifying the replacement process. Subsequently, it can be easily replaced in a single step, and the holder automatically locks when the squeegee is placed back in the holder. This reduces squeegee changeover time by up to 50 percent. In addition, a mechanical pin prevents the squeegee from being installed incorrectly. The quick-change squeegee unit can be retrofitted in a few hours and is compatible with both DEK TQ and NeoHorizon platforms.

Goldsmith went on to add, “SMT production is becoming increasingly competitive, and standing out in this field requires a continuous drive to automate and streamline operations. Asmpt Dek Printer understands the challenges faced by SMT manufacturers and is committed to providing its customers with unique solutions to help them stay ahead of the competition competitive marketplace.”

About Asmpt Dek Printer

Headquartered in Singapore, Asmpt Dek Printer is a leading global supplier of hardware and software solutions for semiconductor and electronics manufacturing. Asmpt Dek Printer’s products range from semiconductor assembly, packaging, and SMT (surface mount technology), from wafer deposition to a variety of solutions for organizing, assembling, and packaging of precision electronic assemblies for a wide range of end-use electronic devices such as electronics, mobile communication devices, computing devices, automotive, industrial, and LED (display) products.

Asmpt Dek Printer is used in the manufacture of a wide range of end-use electronic devices such as electronics, mobile communication devices, computing devices, automotive, industrial, and LED (display). Working closely with customers, Asmpt Dek Printer continues to invest in research and development to develop cost-effective and industry-impactful solutions that contribute to customers’ increased productivity, reliability and quality.

ASMPT (HKEx stock code: 0522) is one of the constituent stocks of the Hang Seng Composite Mid Cap Index under the Hang Seng Composite Market Capitalization Index, the Hang Seng Composite IT Industry Index under the Hang Seng Composite Industry Index, and the Hang Seng Hong Kong 35 Index.

Asmpt Dek Printer Solution

The mission of the ASMPT DEK Printer Solutions Division is to implement and support SMT-integrated smart factories for global electronics manufacturers. ASMPT DEK Printer Solutions supports the networking, automation and optimization of online and factory-level central workflows through hardware, software and services, enabling electronics manufacturers to transition to smart factories in phases and significantly improve productivity, flexibility and quality.

With its holistic “Open Automation” concept, ASMPT DEK Printer opens the door to cost-effective automation that is modular, flexible, and non-proprietary and tailored to their individual needs. The company’s portfolio of products and services includes hardware and software such as SIPLACE placement machines, DEK printers, inspection and material storage solutions, as well as intelligent shop floor management suites.

With Works, ASMPT DEK Printer provides electronics manufacturers with high-quality software for planning, controlling, analyzing and optimizing all processes in the shop floor. As maintaining close relationships with customers and partners is a core component of its strategy, ASMPT has established the SMT Smart Network as a platform for the active exchange of information between individual smart factories around the world.