MPM MOMENTUM ; MPM 125 , MPM MOMENTUM BTB , MPM 100 , MPM EDISON , MPM MOMENTUM HIE ,SPEEDLINE , ITW EAE,MPM SPARE PARTS , MPM UP2000 , MPM ACCUFLEX,MPM ACCELA ,MPM AP EXCEL ,MPM AP , MPM UP3000 , MPM UP1500 , CAMALOT PRODIGY , CAMALOT 8300 , Camalot Dispensers , MPM PRINTER PARTS .

1014290 KIT/KIT,CAMERA CABLE

1015454 CYLINDER,CLAMPING

P12422 CABLE

P7214 BEARING,LINEAR,5MM X 3.7MM X 30MM,1CAR

47167

47661 CABLE,EXTENDED I/O,ASSY

47662 CABLE,EXTENDED I/O,ASSY

47672 CABLE ASSY, DOOR LOCK

47673 CABLE ASSY,SERVICE STATION

47714 CABLE ASSY,Z-SENSE ,Camalot

47717 CABLE ASSY, CAMERA POWER

47767 KIT,PNEUMATIC ENTRANCE

47830 CABLE ASSY,PUMP,28P-16P

47876 CABLE, DOOR INTERLOCK, ASSY DISPENSER FXD

47919 SPRING,GAS,120 LBS ,Camalot

47942 CIRCUIT BREAKER 5A 2P

48092 LED,WHT,24V AC/DC,T1.75

48320 POWER SUPPLY,5VDC,8A

48384 SENSOR ASSY,PHOTOELECT

50163 CABLE,WEIGHT SCALE ASSY

49703-2 CABLE ASSY,LONG STACK

49727-1 CABLE ASSY,SST PUMP,RT

49727-2 CABLE ASSY,SST PUMP,LT,

P1477 PUSH-ON.875 ID,STL

P12042 MONITOR WIDESCREE19 LCD

48644 CONTACT/NONCONTACTASSY,12X10

1019733 BOARD,RING LIGHT HIGH OUTPUT 2550CD,ASSY

46952 CAMERA,BLK-WHT,NTSC,CUBE

50070+31

P9986 CAMERA,BLK-WHT,CCD,768H

1015392 KIT,SERVICE,BOARD ARRAY,

1000755 WINDOW,HOOD LIFT

P10503 BEARING,LINEAR,15MM X 14.5MM X 1180MM.3 CARS

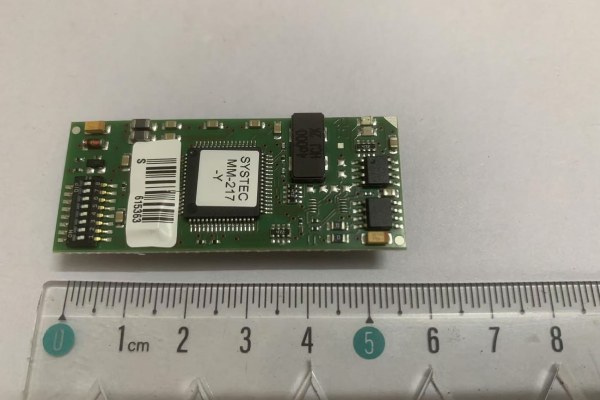

1015915 MODULE,STEPPER DRIVE II, W/FW,NODE ID/BIT RATE

P4251 CONTACTOR,THREE POLE,20A,24V

P12996-50 SEAL BIG

P12995-50 SEAL SMALL

44296 GAUGE,PRESSURE,1.5 DIA,0-140 PSI

P10150 COUPLING,FLEX

P10886 FILTER,SOLVENT,74UM SS,

48496 COUPLING,X&Y LEADSCREWS 8000-1

48495 CYLINDER,Z BRAKE 8000-1

1016495 SHAFT,IDLER,WIPER,ASSY

1022120 KNOB,BUMBER ADJUSTING SST

1020901 NANOSHOT 1020366

Traditional metal screens excel in the printing of many electronic materials on rigid and flexible PCBs. These materials include solder masks and resists, fluxes and solder pastes, and especially conductive inks (silver, carbon, silver chloride), and dielectric inks, both used to form conductive traces, capacitor and resistor elements. Once cured, these materials form the basis for electronic assemblies used in medical/biomedical, sensor, membrane touch switch, flexible display, and many other types of products including consumer electronics. In both PCB and semiconductor applications, MPM® Printers are an ideal solution for screen printing applications.

For decades, Camalot® has been the global leader in dispensing technology for electronic materials. From board-level assembly to advanced packaging to cutting-edge compound semiconductors, Camalot’s innovative solutions have kept our dispense systems solutions in the forefront.

The MPM Momentum II stencil printer is a proven, highly productive printer platform with industry leading accuracy and repeatability (certified by third party). Enhanced technologies provide further improvement around machine productivity, yield, ease of use, and flexibility.

The Momentum II Elite stencil printer is the top-performer of the Momentum series, boasting the highest throughput and shortest cycle times of all. Its vision system is driven by servos for speed, and it’s configured with a highly-efficient triple track rail system that saves cycle time by buffering PCBs inside the machine. A new board is indexed into the machine and positioned next to the center nest, readying to print, while other boards are being loaded and offloaded.

The Momentum II is designed for high throughput and accuracy. MPM’s rigid frame is welded for low vibrations and major assemblies are driven by precision ball screws. This allows for higher repeatability and greater reliability over time.

Momentum II has an advanced print head featuring a high precision load cell with closed loop pressure control for precise and consistent squeegee force. Tighter performance tolerances mean consistent repeatability with higher yield.

The Camalot Prodigy dispensing machine uses cutting-edge technology to achieve faster processing, greater accuracy, and improved yields. The machine’s X Y gantry system, linear drive technology, refined motion control, and sturdy frame design provide excellent performance and reliability.

With the advanced linear-drive architecture and stable frame, the Prodigy can achieve high precision at high speeds, resulting in consistently better yields with a +/- 35µ 3 Sigma dot placement accuracy at full speed.

The machine also has an innovative board staging option that can double or even triple the dispense area in the X direction, allowing for processing of products up to 900mm in size.

Both contact and non-contact heating options, including heated lift chucks, ensure that dispense materials are maintained at a controlled temperature for consistent, repeatable material flow rates for underfill and encapsulation.

The Prodigy’s features can be easily upgraded in the field, due to its “plug and play” compatibility and simplicity. This includes upgrades to heat, pumps, weight scale, 2nd Z-axis, and even the conveyor system.