Axxon Mycronic’s MYD50X Precision Dispenser: Elevating Precision in Electronics Manufacturing

In the rapidly evolving landscape of electronics manufacturing, precision and efficiency are paramount. Axxon Mycronic has emerged as a leader in this field, offering advanced dispensing solutions that cater to the demanding needs of modern applications. One of the standout products in their lineup is the MYD50X precision dispenser, which integrates cutting-edge technology to deliver unmatched accuracy and reliability. This article explores the MYD50X’s features, applications, and its significant impact on various sectors, particularly consumer electronics.

The Technology Behind MYD50X

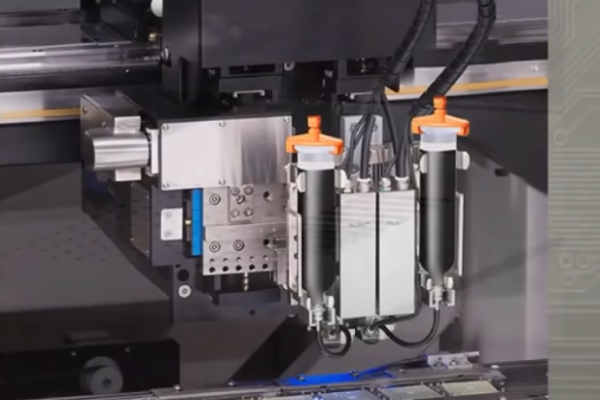

At the heart of the Axxon Mycronic MYD50X is its closed-loop linear motor system. This innovative technology allows the dispenser to achieve micron-level accuracy, essential for high-precision applications. Traditional dispensing methods often suffer from inconsistencies due to mechanical wear and environmental factors, leading to variations in application thickness and placement. The closed-loop system of the Axxon Mycronic MYD50X mitigates these issues by continuously monitoring and adjusting the dispensing process in real-time, ensuring that each application meets stringent quality standards.

Moreover, the Axxon Mycronic MYD50X is designed to accommodate a wide range of materials, including hot melts, underfills, and surface mount adhesives (SMA). This versatility makes it an invaluable asset for manufacturers looking to optimize their production processes while maintaining high levels of precision and efficiency.

Key Applications of the Axxon Mycronic MYD50X

- Hot Melt Adhesives: The Axxon Mycronic MYD50X excels in applications requiring hot melt adhesives, which are widely used for bonding in various consumer electronics. The precision dispenser can handle varying viscosities and application profiles, ensuring that the adhesive is applied uniformly and accurately.

- Underfill Materials: In the assembly of semiconductor devices, underfill materials play a critical role in enhancing reliability and performance. The MYD50X’s ability to dispense underfill with micron-level accuracy helps prevent common issues such as delamination and thermal stress.

- Pin Encapsulation: For applications where pins or leads need protection from environmental factors, the MYD50X provides reliable pin encapsulation. Its precision ensures that the encapsulation material is applied only where needed, minimizing waste and enhancing the integrity of the assembly.

- Edge and Corner Bonding: The Axxon Mycronic MYD50X is particularly effective in edge and corner bonding applications, which are common in the assembly of display screens and other components. Its ability to precisely control the adhesive flow enables manufacturers to achieve strong bonds without compromising the aesthetic quality of the product.

- Surface Mount Adhesive (SMA): In surface mount technology, the Axxon Mycronic MYD50X is a game changer. It allows for accurate application of SMA, ensuring that components are securely attached while facilitating efficient production processes.

- Package-on-Package (PoP) Assembly: The increasing complexity of electronic devices has led to the rise of package-on-package assembly techniques. The Axxon Mycronic MYD50X’s precision dispensing capabilities are crucial for applying adhesives in these multilayer configurations, ensuring robust interconnections.

- Dam and Fill Applications: The MYD50X is adept at dam and fill processes, where controlled amounts of material are needed to create barriers and fill cavities in electronic assemblies. This capability is vital for enhancing the performance and durability of products.

- Flexible Printed Circuit (FPC) Component Assembly: As the demand for flexible electronics grows, so does the need for precise assembly techniques. The Axxon Mycronic MYD50X can effectively handle the delicate nature of FPC components, ensuring accurate placement and adhesion.

- Reinforcement Materials: In consumer electronics, reinforcement materials are often used to enhance structural integrity. The Axxon Mycronic MYD50X’s precise dispensing technology ensures that these materials are applied in the right amounts and locations, improving the overall durability of the final product.

Benefits of Using the Axxon Mycronic MYD50X

The implementation of the Axxon Mycronic MYD50X precision dispenser offers several significant benefits for manufacturers:

- Enhanced Precision: With its closed-loop linear motor system, the Axxon Mycronic MYD50X ensures consistent and accurate dispensing, reducing the likelihood of defects and rework.

- Increased Efficiency: By minimizing waste and optimizing material usage, the Axxon Mycronic MYD50X helps manufacturers streamline their processes, leading to higher productivity and reduced costs.

- Versatility: The Axxon Mycronic MYD50X can handle a wide range of materials and applications, making it a flexible solution for various manufacturing environments. This adaptability allows manufacturers to respond quickly to changing market demands.

- Improved Product Quality: The precision and control offered by the Axxon Mycronic MYD50X result in higher quality finished products, which can enhance brand reputation and customer satisfaction.

- Reduced Downtime: The reliable performance of the Axxon Mycronic MYD50X means less time spent on maintenance and troubleshooting, allowing manufacturers to maximize operational uptime.

Conclusion

In a world where electronic devices are becoming increasingly complex and miniaturized, the demand for precision in manufacturing is more critical than ever. Axxon Mycronic’s MYD50X precision dispenser stands out as a leading solution that addresses these challenges head-on. With its advanced closed-loop linear motor technology, the MYD50X delivers micron-level accuracy across a range of applications, from hot melt adhesives to underfills and package-on-package assemblies.

The Axxon Mycronic MYD50X not only enhances the manufacturing process but also contributes to the overall quality and reliability of consumer electronics. As technology continues to advance, the MYD50X positions itself as an essential tool for manufacturers striving to meet the demands of a competitive market. By embracing the capabilities of the MYD50X, companies can ensure that they remain at the forefront of innovation in the electronics industry, ultimately delivering superior products to consumers worldwide.

Axxon Mycronic’s MYD50X Product features

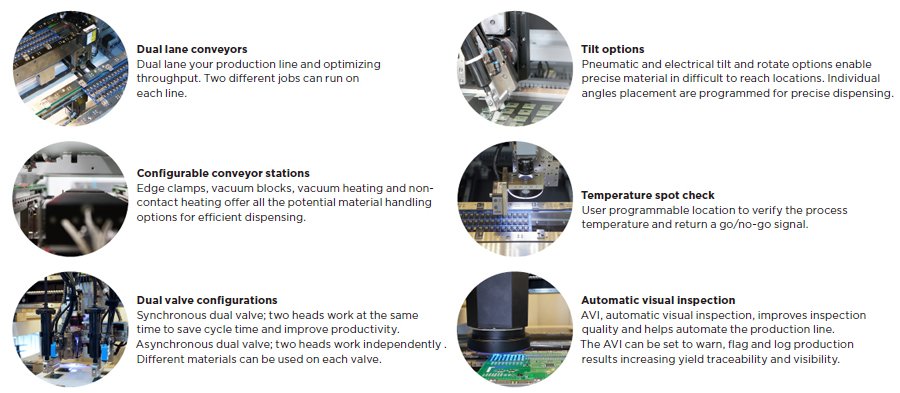

FLEXIBLE

MYD series can handle different substrate sizes and compositions to meet specific process requirements.

Numerous applications can be achieved with optional features such as tilt and rotate, contact

and non-contact heating and dual head configurations.

COST-EFFICIENT

Smaller machine dimensions, high quality build and streamlined mechanical design allow the system to

run for longer periods of time with less maintenance and lower downtimes. Our Piezo Jetting technology

has been designed with a reduced number of wear parts further reducing the cost of ownership making

the MYD series a cost-effective dispensing solution.

IMPROVED PRODUCTIVITY

Precise temperature controls, on-the-fly fiducial search, robust vision algorithms, low motion Z axis

and non-contact dispensing are some feautures to increase productivity.

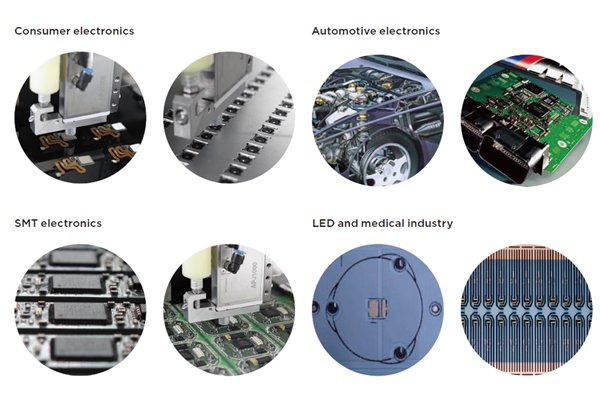

KEY APPLICATIONS,CONSUMER ELECTRONICS

• Hot melt • Underfill • Pin encapsulation • Edge/corner bonding • Surface mount package

• Package on package • Dam and fill • SMA • FPC component • Reinforcement materials

Axxon Mycronic MYD50X Specifications

| Specification | MYD50X |

| Power supply | AC 200~240V,1.8kW,8A,50/60Hz |

| Air supply | 90psi(6bar) |

| Dimension | 770x1300x1530mm(WxDxH) |

| Weight | 1350kg |

| Standard compliance | CE |

| Dispense area | |

| Max dispensing area (single lane/dual lane) | 350x500mm/350x218mm(WxD) |

| Synchronized dual valve – automaticadjustment (single lane/dual lane) | 315x405mm/315x160mm(WxD) |

| Asynchronized dual valve (single lane/dual lane) | 290x430mm/290x183mm(WxD) |

| Tilt & rotation (single lane/dual lane) | 270x410mm/270x173mm(WxD) |