Overview of Axxon Mycronic MYD50S Dispensing System

Axxon Mycronic MYD50S is an advanced inline dispensing system specifically engineered to meet the high standards required in the semiconductor industry, particularly for chip packaging applications. As semiconductor technology rapidly advances, the demand for precise, high-speed, and cost-effective dispensing solutions has grown exponentially. The MYD50S stands out by addressing these demands with innovative design and superior technology, ensuring accuracy, reliability, and efficiency 1.

Key Features of the Axxon Mycronic MYD50S

1. Micron-Resolution Grating Scale

- Axxon Mycronic MYD50S incorporates a micron-resolution grating scale, a pivotal feature that significantly enhances dispensing precision. This high-resolution grating scale allows the system to measure and control dispensing parameters down to the micron level, ensuring minimal deviation from target placements.

- In applications like chip packaging, where component placement is tightly controlled to avoid overlaps, misalignment, or wastage, the micron-scale precision of MYD50S is invaluable.

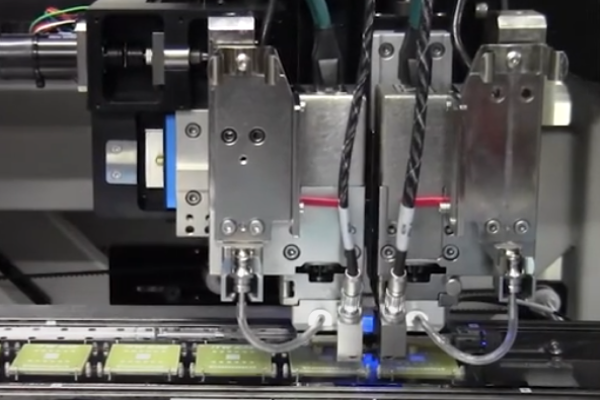

2. Closed-Loop Control in Linear Motor Motion System

- A robust closed-loop control system, integrated with a linear motor motion mechanism, enables the Axxon Mycronic MYD50S to achieve consistent and stable performance. The closed-loop control continuously monitors and adjusts the position of the dispensing head, effectively minimizing errors and compensating for any deviations caused by environmental factors or mechanical wear.

- This is particularly beneficial in high-speed applications, as it maintains stability and consistency even at elevated operational speeds, crucial in environments demanding both speed and accuracy.

3. User-Friendly Graphical User Interface (GUI)

- A well-designed user interface is fundamental to maximizing productivity and ease of use. The Axxon Mycronic MYD50S features an intuitive and user-friendly GUI that streamlines setup, calibration, and operation, allowing users to configure complex dispensing tasks with minimal effort.

- This is not only time-efficient but also reduces training requirements for operators, facilitating a smoother onboarding process and greater operator confidence in the machine’s capabilities.

4. Precision in High-Speed Dispensing

- One of the most critical aspects of the Axxon Mycronic MYD50S is its high-speed dispensing capabilities without compromising on precision. The system is engineered to handle demanding production cycles typical of the semiconductor industry, where large volumes of tiny components need to be placed accurately and quickly.

- With a dispensing area of up to 350x500mm, the Axxon Mycronic MYD50S is equipped to handle a wide range of chip packaging applications, from small-scale projects to extensive production runs. This flexibility makes it an adaptable solution across different semiconductor manufacturing requirements.

5. High Reliability and Cost Efficiency

- In a competitive market where reliability and cost efficiency are crucial, the Axxon Mycronic MYD50S shines with its long-lasting performance and low operational costs. By integrating advanced technologies like the closed-loop control system, high-precision grating scale, and a robust linear motor, the machine requires minimal maintenance while delivering consistently high output.

- Additionally, the cost-effective nature of the Axxon Mycronic MYD50S provides an attractive ROI for manufacturers looking to improve production quality and efficiency without extensive investment in more costly, complex equipment.

Applications of the Axxon Mycronic MYD50S in Semiconductor Chip Packaging

The semiconductor industry relies on chip packaging processes to protect delicate components from environmental hazards and to enable reliable connections to external circuits. The Axxon Mycronic MYD50S plays a pivotal role in this field by facilitating high-precision dispensing tasks in various packaging methods:

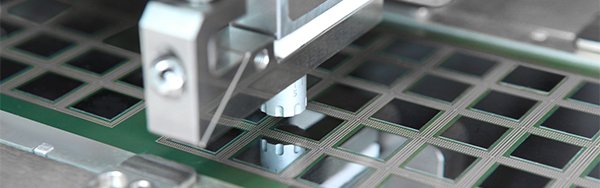

- Underfill Dispensing

- Underfill encapsulants are dispensed around flip-chip components to protect the solder joints from thermal and mechanical stress. The Axxon Mycronic MYD50S, with its precise control, ensures even and controlled application of underfill materials, preventing voids or uneven coverage that could compromise reliability.

- Dam and Fill Encapsulation

- For certain packages, a dam and fill approach is used, where a “dam” material is applied to create a boundary, and a filler material is dispensed inside the boundary. The Axxon Mycronic MYD50S is capable of both creating fine, high-precision barriers and efficiently filling encapsulant materials within those boundaries, ensuring both structural integrity and protection.

- Cavity Fill for 3D Packaging

- The Axxon Mycronic MYD50S is also effective in cavity filling applications, often required in 3D package architectures. These structures demand accurate dispensing within confined spaces, and the MYD50S’s micron-level precision ensures optimal material application even in complex geometries.

- Conductive Adhesive Dispensing

- In some chip packages, conductive adhesives are used to form electrical connections. The Axxon Mycronic MYD50S’s closed-loop precision control makes it well-suited for these tasks, ensuring a consistent volume and position of adhesive, which is vital for electrical connectivity and performance.

Benefits of Axxon Mycronic MYD50S High-Precision Dispensing

1. Enhanced Product Quality

- High precision in dispensing directly correlates with improved product quality. Accurate application of adhesives, underfill, or encapsulants ensures uniformity across chip packages, reducing the likelihood of defects and prolonging product lifespan.

2. Reduced Material Waste

- Precise dispensing control minimizes material wastage, as only the required amount of material is used without unnecessary overdispensing. This not only cuts material costs but also supports sustainability initiatives by reducing excess material consumption.

3. Increased Throughput

- The high-speed nature of Axxon Mycronic MYD50S ensures faster cycle times, essential for meeting production demands in the semiconductor industry. Increased throughput means that manufacturers can handle larger volumes without additional equipment, optimizing factory floor space and resources.

4. Versatile Application Range

- With the ability to handle a wide variety of dispensing materials and applications, the Axxon Mycronic MYD50S is a versatile tool for manufacturers. Whether dealing with different encapsulants, adhesives, or fillers, the MYD50S can be adapted to meet varying production needs.

Competitive Advantage of the MYD50S in the Semiconductor Industry

The semiconductor industry is highly competitive, and manufacturers are constantly seeking equipment that delivers superior quality and efficiency. The Axxon Mycronic MYD50S offers a unique blend of features that sets it apart from traditional dispensing systems:

- Micron-Level Precision: Essential for modern chip packaging requirements, the Axxon Mycronic MYD50S’s micron resolution ensures the highest level of accuracy, meeting stringent industry standards.

- Reliability in High-Speed Applications: The linear motor and closed-loop control enable stable performance at high speeds, making the Axxon Mycronic MYD50S ideal for large-scale operations without sacrificing accuracy.

- Ease of Use with Advanced GUI: The user-friendly interface empowers operators to set up and execute complex dispensing tasks with minimal training, reducing setup time and increasing overall productivity.

- Cost-Effective Operations: With minimal maintenance needs and efficient material usage, the Axxon Mycronic MYD50S provides an excellent cost-to-performance ratio, making it an attractive investment for manufacturers aiming to boost profitability.

Axxon Mycronic Axxon Mycronic MYD50S inline high-speed dispensing system is a state-of-the-art solution designed to address the specific challenges faced by the semiconductor industry in chip packaging applications. Through its advanced features like micron-resolution grating scale, closed-loop control, user-friendly GUI, and precise dispensing capabilities, the MYD50S offers a comprehensive solution that enhances productivity, reduces costs, and improves the quality of semiconductor products. In a market driven by constant innovation and miniaturization, the Axxon Mycronic MYD50S stands as a reliable and cost-effective choice for manufacturers aiming to maintain a competitive edge while ensuring the highest standards of product quality.

Product Features

MYD50S inline high-speed dispensing system for semiconductor industry.

– Unsurpassed value by combining high-end technology with low total cost of ownership.

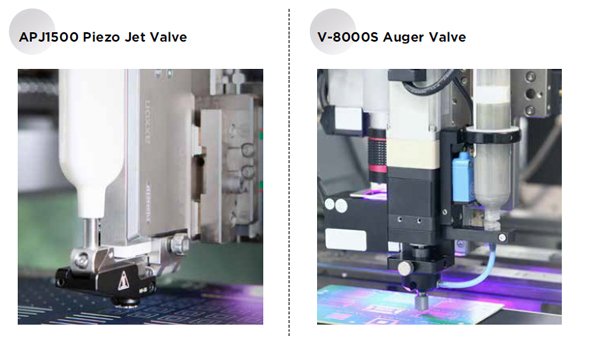

– From underfill to solder paste the MYD series offers many unique jetting technology, offering enhanced flexibility for high volume manufacturing.

– Built-in-AVI capabilities enable automatic inspection of dispense results.

– Class 10000 cleanroom (standard).

– ESD safe.

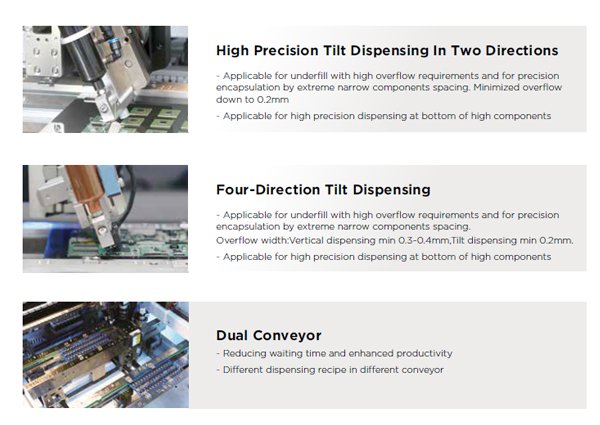

OPTIONAL CONFIGURATIONS

KEY COMPONENTS

SEMICONDUCTOR INDUSTRIES INLINE JETTING APPLICATIONS

• Flip Chip Underfill • Dome Coating • Solder Paste Dispensing For MEMS • No-Flow Underfill

• Dam&Fill-COB Package • Glob Top-COB Package • Solder Paste • SMA • Silver Paste Dispensing

• Tim Dispensing • Wafer Underfill • Flux Dispensing

Specifications

| Specification | MYD50S |

| Power supply | AC 200~240V,8A,50/60Hz,1.8kW, Conveyor heating 1.8kW |

| Air supply | 90psi(6bar) |

| Dimension | 1050x1300x1530mm(WxDxH) |

| Weight | 1370kg |

| Standard compliance | CE,SEMI S2 |

| Dispense area | |

| Max dispensing area (single lane/dual lane) | 350x500mm/350x205mm(WxD) |

| Synchronized dual valve – automaticadjustment (single lane/dual lane) | 315x405mm/315x157mm(WxD) |

| Asynchronized dual valve (single lane/dual lane) | 290x430mm/290x170mm(WxD) |

| Tilt & rotation (single lane/dual lane) | 270x410mm/270x160mm(WxD) |