Axxon Mycronic MYD50C is a state-of-the-art inline dispensing system engineered specifically for the semiconductor industry, operating within a Class 1000 cleanroom environment. As semiconductor manufacturing processes become increasingly complex, the need for precise and efficient material application has never been more critical. The MYD50C addresses this challenge by integrating high-speed dispensing technology with exceptional accuracy, ensuring optimal performance in demanding production settings.

Designed for flexibility, the Axxon Mycronic MYD50C accommodates a wide range of materials, including adhesives, sealants, and encapsulants, making it a versatile solution for various applications. Its advanced dispensing mechanisms are complemented by intelligent control systems that enhance operational efficiency and minimize waste, aligning with the industry’s sustainability goals.

Moreover, the Axxon Mycronic MYD50C features robust monitoring capabilities, allowing operators to maintain stringent quality standards throughout the manufacturing process. By combining cutting-edge technology with user-friendly interfaces, the MYD50C empowers semiconductor manufacturers to achieve higher throughput and superior product quality. In a sector where precision is paramount, the Axxon Mycronic MYD50C stands out as a reliable partner for driving innovation and productivity in semiconductor production.

Axxon Mycronic MYD50C: Linear Motor & Clean Room High-Speed Inline Dispensing System

The Axxon Mycronic MYD50C is a cutting-edge linear motor-driven dispensing system designed for high-speed applications in semiconductor manufacturing and other precision industries. Engineered to operate seamlessly in Class 1000 cleanroom environments, the MYD50C combines advanced technology with rigorous cleanliness standards, ensuring optimal performance and reliability for various dispensing tasks.

Linear Motor Technology

At the heart of the Axxon Mycronic MYD50C exceptional performance is its advanced linear motor technology. This innovative design eliminates the friction and wear associated with traditional mechanical systems, enabling rapid acceleration and deceleration. The result is unparalleled speed and precision in dispensing processes, crucial for high-volume production lines where time and accuracy are paramount. The linear motor’s capability allows the MYD50C to maintain tight tolerances, ensuring that every dispense is consistent and reliable, which is essential for applications such as flip chip underfill and solder paste dispensing.

Versatile Dispensing Applications

The Axxon Mycronic MYD50C is engineered to handle a wide range of materials, including underfills, adhesives, solder pastes, and thermal interface materials (TIMs). Its versatility makes it suitable for various applications, from semiconductor packaging to electronic assembly. The system’s advanced jetting technology allows for precise control over dispense volume and speed, accommodating different material viscosities and properties. This adaptability enhances operational efficiency, enabling manufacturers to switch between tasks quickly without compromising quality.

Cleanroom Compatibility

Operating within a Class 1000 cleanroom is crucial in semiconductor manufacturing, where contamination can severely impact product quality and reliability. The Axxon Mycronic MYD50C is designed with cleanroom standards in mind, featuring materials and designs that minimize particulate generation. Its enclosed dispensing area reduces the risk of contamination, ensuring that the dispensing process remains consistent and reliable.

Built-in Inspection Capabilities

Quality control is a top priority in semiconductor manufacturing, and the Axxon Mycronic MYD50C addresses this need with built-in Automatic Visual Inspection (AVI) capabilities. This feature allows for real-time monitoring of dispensing results, ensuring that each application meets stringent quality standards. The system can detect any deviations in dispense parameters, enabling operators to make immediate adjustments and maintain high levels of quality assurance. This proactive approach to quality control minimizes waste and rework, further enhancing the system’s cost-effectiveness.

The Axxon Mycronic MYD50C linear motor high-speed dispensing system is a vital asset for manufacturers seeking to enhance their production capabilities. By combining advanced linear motor technology with cleanroom compatibility and versatile dispensing options, the MYD50C sets a new standard in precision and efficiency for the semiconductor industry. As the demand for high-quality, reliable electronic components continues to grow, systems like the MYD50C will play a crucial role in driving innovation and success in manufacturing processes.

Axxon Mycronic MYD50C Product features

Axxon Mycronic MYD50C: The Future of Inline High-Speed Dispensing in the Semiconductor Industry

In the fast-evolving world of semiconductor manufacturing, achieving high efficiency and precision while maintaining cost-effectiveness is crucial. The Axxon Mycronic MYD50C inline high-speed dispensing system is at the forefront of this endeavor, seamlessly integrating advanced technology with an emphasis on low total cost of ownership. Designed specifically for the semiconductor industry, the MYD50C offers unparalleled value, ensuring that manufacturers can meet the increasing demands for high-quality production without compromising their budgets.

Unsurpassed Value and Cost Efficiency

One of the standout features of the Axxon Mycronic MYD50C is its ability to deliver exceptional value through high-end technology paired with a low total cost of ownership. In an industry where operational costs can quickly escalate, the MYD50C stands out as a cost-effective solution. By incorporating cutting-edge components and efficient operational practices, the MYD50C reduces the need for frequent maintenance and minimizes downtime. This not only enhances productivity but also ensures that manufacturers can allocate their resources more effectively, resulting in significant cost savings over the system’s lifespan.

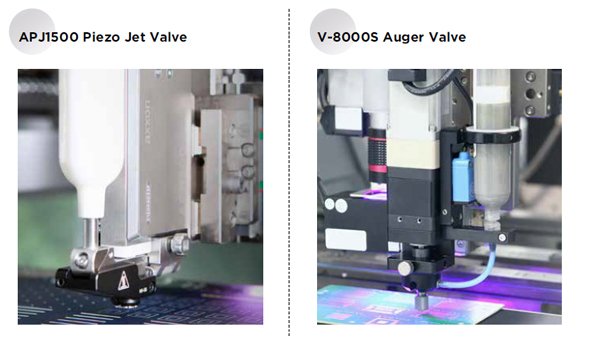

Versatile Jetting Technology

The Axxon Mycronic MYD50C is engineered for flexibility, making it an ideal choice for high-volume manufacturing environments. It boasts a range of unique jetting technologies capable of handling diverse materials, from underfill to solder paste. This versatility is essential as semiconductor production processes often involve multiple material types that require precise application. The MYD50C advanced jetting capabilities enable manufacturers to adapt to varying production needs, streamlining workflows and optimizing overall efficiency.

This adaptability is particularly valuable in today’s fast-paced manufacturing landscape, where rapid product iteration and changes in design specifications are common. By utilizing the Axxon Mycronic MYD50C , manufacturers can easily switch between different dispensing tasks without needing to invest in multiple systems, thereby enhancing operational flexibility.

Built-in Automatic Inspection Capabilities

Quality control is paramount in semiconductor manufacturing, where even the smallest defect can lead to significant failures and financial losses. The Axxon Mycronic MYD50C is equipped with built-in Automatic Visual Inspection (AVI) capabilities, allowing for real-time monitoring of dispensing results. This feature enables manufacturers to maintain strict quality standards, ensuring that every application meets the required specifications.

The AVI system enhances the overall reliability of the production process by providing immediate feedback on dispense accuracy. In the event of a deviation from the desired parameters, the system can alert operators to potential issues, allowing for prompt corrective actions. This proactive approach to quality assurance not only minimizes waste and rework but also boosts customer confidence in the final product.

Class 1000 Cleanroom Compatibility

Operating within a Class 1000 cleanroom environment is essential for semiconductor manufacturing to prevent contamination and ensure product integrity. The Axxon Mycronic MYD50C is designed to meet these stringent cleanliness standards, making it suitable for use in controlled environments. Its design minimizes particulate generation, and every aspect of the system is optimized to maintain cleanliness, from the dispensing nozzles to the surrounding infrastructure.

This adherence to cleanroom standards is crucial, as even minor contaminants can compromise the performance of semiconductor devices. By utilizing the Axxon Mycronic MYD50C , manufacturers can ensure that their production processes align with industry regulations and best practices, safeguarding the quality and reliability of their products.

ESD Safety for Sensitive Components

Electrostatic discharge (ESD) poses a significant risk in semiconductor manufacturing, where sensitive electronic components can be easily damaged. The Axxon Mycronic MYD50C incorporates ESD-safe features to protect both the dispensing equipment and the components being processed. This ESD safety is critical, as it mitigates the risk of failures that could arise from static electricity, ultimately prolonging the lifespan of the equipment and reducing the likelihood of costly errors.

By prioritizing ESD safety, the Axxon Mycronic MYD50C enhances the overall reliability of the production process. Manufacturers can operate with confidence, knowing that their investment in advanced technology is safeguarded against one of the most common and preventable sources of damage in semiconductor production.

The Axxon Mycronic MYD50C inline high-speed dispensing system represents a significant advancement in semiconductor manufacturing technology. By combining high-end features with a focus on cost efficiency, the MYD50C stands out as a premier solution for manufacturers seeking to enhance their production capabilities.

With its versatile jetting technology, built-in AVI capabilities, Class 1000 cleanroom compatibility, and ESD safety measures, the Axxon Mycronic MYD50C is designed to meet the rigorous demands of modern semiconductor production. As the industry continues to evolve, systems like the MYD50C will play a pivotal role in driving innovation and ensuring that manufacturers can keep pace with the ever-growing expectations for quality and efficiency.

Investing in the Axxon Mycronic MYD50C not only enhances productivity and quality but also positions manufacturers at the forefront of technological advancement in the semiconductor industry. With its exceptional performance and unwavering commitment to quality, the MYD50C is a reliable partner for manufacturers striving for excellence in their production processes.

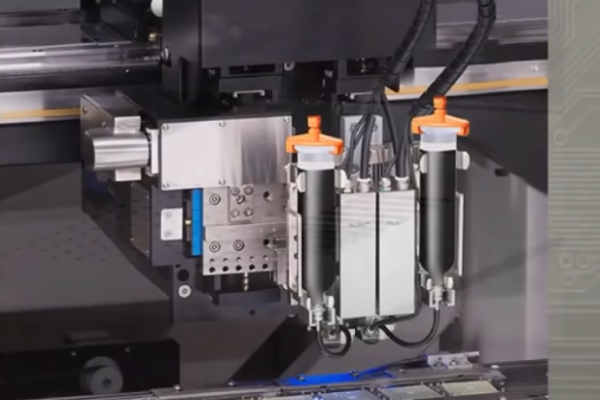

OPTIONAL CONFIGURATIONS

KEY COMPONENTS

SEMICONDUCTOR INDUSTRIES INLINE JETTING APPLICATIONS

Advanced Dispensing Solutions for the Semiconductor Industry

In the ever-evolving semiconductor industry, the demand for precision and efficiency in material application is paramount. As manufacturers seek to enhance the performance and reliability of their products, advanced dispensing technologies have emerged as critical components in various processes. The Axxon Mycronic MYD50C inline high-speed dispensing system supports a wide range of applications, including flip chip underfill, dome coating, solder paste dispensing for MEMS, and more. This article delves into these key dispensing solutions, highlighting their significance in modern semiconductor manufacturing.

Flip Chip Underfill

Flip chip technology has revolutionized semiconductor packaging, allowing for higher interconnect density and improved thermal performance. However, the implementation of flip chip assemblies necessitates the effective application of underfill materials. Flip chip underfill dispenses a low-viscosity resin into the gap between the chip and substrate, ensuring mechanical stability and thermal cycling reliability.

The Axxon Mycronic MYD50C excels in this application, providing precise control over the dispense process. This precision ensures that the underfill material flows evenly, preventing voids and ensuring strong adhesion. By maintaining tight tolerances, the MYD50C enhances the reliability of flip chip assemblies, ultimately improving the performance of the final product.

Dome Coating

Dome coating is a protective layer applied over sensitive electronic components, shielding them from environmental factors such as moisture, dust, and mechanical stress. This coating is critical in extending the lifespan of semiconductor devices, particularly in harsh operating conditions.

The Axxon Mycronic MYD50C advanced jetting technology enables manufacturers to achieve consistent dome shapes with minimal overspray. This precision is crucial for ensuring that the protective coating adequately covers the components without adding unnecessary weight or bulk. Furthermore, the system’s speed and efficiency allow for high-volume production without compromising quality.

Solder Paste Dispensing for MEMS

Micro-electromechanical systems (MEMS) are at the forefront of technological innovation, powering devices in sectors ranging from automotive to healthcare. The assembly of MEMS often requires the application of solder paste, which plays a vital role in ensuring reliable electrical connections.

The Axxon Mycronic MYD50C is adept at dispensing solder paste with high accuracy, essential for the miniaturized components characteristic of MEMS. Its ability to handle various paste viscosities and particle sizes ensures that manufacturers can adapt to different MEMS designs without needing multiple systems. This versatility not only streamlines production processes but also enhances the quality and reliability of the solder joints.

No-Flow Underfill

No-flow underfill materials offer significant advantages in flip chip packaging by eliminating the need for capillary action to fill the gap between the chip and substrate. Instead, these materials remain in a pre-applied state until cured, reducing the risk of contamination and providing better control over the assembly process.

The Axxon Mycronic MYD50C supports the application of no-flow underfill with high precision, ensuring that the material is dispensed in the correct quantities and locations. This capability enhances the overall quality of the assembly while minimizing waste and reducing production costs.

Dam & Fill – COB Package

Chip-on-Board (COB) packaging is widely used in the semiconductor industry for its ability to maximize circuit density and minimize form factor. The dam & fill process involves creating a barrier (dam) to contain the underfill material around the chip, followed by the filling of the area to ensure complete encapsulation.

The Axxon Mycronic MYD50C precise dispensing capabilities make it an ideal solution for this application. It can create the dam with high accuracy, ensuring that the underfill material stays within the designated area. This level of control minimizes the risk of overfilling or spillage, thereby enhancing the reliability of the COB package.

Glob Top – COB Package

Glob top encapsulation is another crucial process in COB packaging, providing a protective layer over the chip and wire bonds. This encapsulation enhances the mechanical and thermal performance of the assembly while protecting it from environmental factors.

The Axxon Mycronic MYD50C ability to dispense glob top materials with precision is essential for achieving the desired coverage without compromising the integrity of the underlying components. By ensuring that the glob top material is applied uniformly, manufacturers can improve the overall reliability and longevity of the COB packages.

Solder Paste

Solder paste is a critical material in the assembly of printed circuit boards (PCBs) and semiconductor devices. Its effective application directly impacts the quality of solder joints, influencing the overall performance of the final product. The Axxon Mycronic MYD50C provides high-speed and accurate solder paste dispensing, allowing manufacturers to achieve consistent results across various applications.

The system’s advanced control features enable operators to adjust dispense parameters in real-time, ensuring optimal paste volume and placement. This adaptability is vital in today’s fast-paced manufacturing environment, where design changes and variations in component sizes are common.

SMA (Surface Mount Adhesive)

Surface mount adhesives (SMA) are essential for securing components to PCBs before soldering. The application of SMA requires precision to ensure that the adhesive is applied in the correct locations without excess that could affect soldering processes.

The Axxon Mycronic MYD50C excels in dispensing SMA, offering precise control over the adhesive volume and placement. This precision not only enhances the reliability of the components but also ensures that the subsequent soldering process is not compromised, leading to higher quality assemblies.

Silver Paste Dispensing

Silver paste is often used in high-frequency applications due to its excellent conductivity and thermal properties. Dispensing silver paste requires a system capable of handling its unique viscosity and particle size.

The Axxon Mycronic MYD50C advanced dispensing technology allows for accurate and efficient application of silver paste, ensuring optimal performance in electronic devices. This capability is particularly valuable in applications where performance is critical, such as RF components and high-speed circuitry.

TIM (Thermal Interface Material) Dispensing

Effective thermal management is essential in semiconductor devices to prevent overheating and ensure optimal performance. Thermal Interface Materials (TIM) are used to enhance the thermal conductivity between components and heat sinks.

The Axxon Mycronic MYD50C is equipped to dispense TIMs with high precision, ensuring uniform application and eliminating voids that can hinder thermal performance. This capability is crucial in maintaining the reliability and efficiency of high-performance semiconductor devices.

Wafer Underfill

Wafer underfill is a critical process in the fabrication of advanced packaging technologies, where it enhances the reliability of the interconnects between the wafer and the substrate. The Axxon Mycronic MYD50C ability to dispense underfill materials accurately across large areas makes it ideal for this application, ensuring that the material flows evenly into the gaps without trapping air bubbles.

This precision not only improves the overall reliability of the interconnects but also contributes to the longevity of the semiconductor devices. By utilizing the Axxon Mycronic MYD50C for wafer underfill applications, manufacturers can enhance the quality and performance of their products.

Flux Dispensing

Flux is essential in soldering processes, promoting wetting and adhesion of solder to the surfaces being joined. The precise application of flux is vital to ensure optimal soldering results, and the Axxon Mycronic MYD50C delivers outstanding performance in this area.

With its advanced dispensing technology, the Axxon Mycronic MYD50C allows for accurate and controlled flux application, reducing the risk of excess flux that can lead to soldering defects. This level of control contributes to higher quality assemblies and minimizes the potential for rework, enhancing overall manufacturing efficiency.

Conclusion

The Axxon Mycronic MYD50C inline high-speed dispensing system is a powerful solution for the diverse needs of the semiconductor industry. From flip chip underfill to flux dispensing, its advanced capabilities enable manufacturers to achieve high precision and efficiency across various applications. By investing in the MYD50C, semiconductor manufacturers can enhance their production processes, ensuring high-quality products that meet the ever-increasing demands of the market. As technology continues to advance, systems like the MYD50C will play a crucial role in driving innovation and success in semiconductor manufacturing.

Axxon Mycronic MYD50C Specifications

| Specification | MYD50C |

| Power supply | AC 200~240V,8A,50/60Hz,1.8kW, Conveyor heating 1.8kW |

| Air supply | 90psi(6bar) |

| Dimension | 770x1300x1800mm(WxDxH) |

| Weight | 1350kg |

| Standard compliance | CE,SEMI S2 |

| Dispense area | |

| Max dispensing area (single lane/dual lane) | 350x500mm/350x218mm(WxD) |

| Synchronized dual valve – automaticadjustment (single lane/dual lane) | 315x405mm/315x160mm(WxD) |

| Asynchronized dual valve (single lane/dual lane) | 290x430mm/290x183mm(WxD) |

| Tilt & rotation (single lane/dual lane) | 270x410mm/270x173mm(WxD) |