In the fast-paced world of manufacturing, precision and efficiency are not just desirable—they are essential. As industries strive to enhance their production capabilities, innovative technologies are emerging to meet these demands.

Axxon Mycronic jetting valves stand out as a revolutionary solution for dispensing materials with exceptional accuracy. In this article, I will explore how these advanced valves operate, their applications across various sectors, and whether they truly represent the Future of precision dispensing.

With our expectations set, let’s delve deeper into the world of Axxon Mycronic jetting valves. Understanding their mechanics and applications is crucial for anyone looking to enhance their manufacturing processes.

Contents

- What Are Axxon Mycronic Jetting Valves?

- Which Industries Benefit from Jetting Technology?

- How Do Jetting Valves Compare to Traditional Dispensing Methods?

- What Does the Future Hold for Jetting Technology?

What Are Axxon Mycronic Jetting Valves?

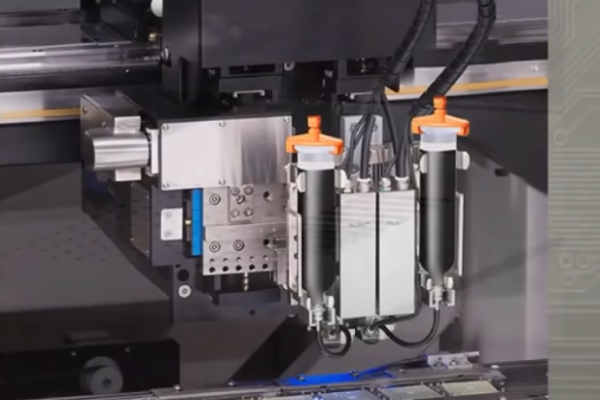

These jetting valves utilize pneumatic or piezoelectric actuation to eject droplets through a nozzle, providing exceptional accuracy and repeatability in various applications. They can handle a wide range of materials, including adhesives, solder pastes, and inks.

Axxon Mycronic jetting valves are sophisticated dispensing devices designed to deliver precise amounts of fluid materials onto substrates without making direct contact. This non-contact method allows for rapid application while minimizing waste—qualities that make these valves ideal for high-speed production environments.

The technology behind Axxon Mycronic jetting valves is both advanced and practical. For instance, their ability to manage low-viscosity fluids while maintaining speed and accuracy makes them particularly valuable in electronics manufacturing. In my experience working with manufacturers who have implemented these valves, I have seen significant reductions in material waste and increased throughput.One notable case study involved an electronics manufacturer that integrated Axxon Mycronic jetting valves into its assembly line.

The result was a remarkable 30% increase in production speed without compromising quality standards. This example illustrates how adopting advanced dispensing technologies can lead to substantial improvements in operational efficiency.Moreover, the versatility of these valves allows them to be used across various applications beyond electronics, including automotive and medical device manufacturing. Their adaptability makes them an attractive option for manufacturers looking to streamline operations.

Research published in the Journal of Manufacturing Processes supports claims regarding precision and efficiency, indicating that companies utilizing advanced jetting technologies have documented up to a 25% reduction in defect rates compared to traditional dispensing methods. This data underscores the effectiveness of Axxon Mycronic jetting valves in enhancing product quality.

Which Industries Benefit from Jetting Technology?

Jetting technology is not confined to a single sector; its applications span multiple industries, each reaping unique benefits from its implementation. Identifying these sectors can provide insights into potential opportunities for adoption.

Industries such as electronics manufacturing, automotive production, and medical device fabrication benefit significantly from Axxon Mycronic jetting valves due to their high demand for precision and reliability.

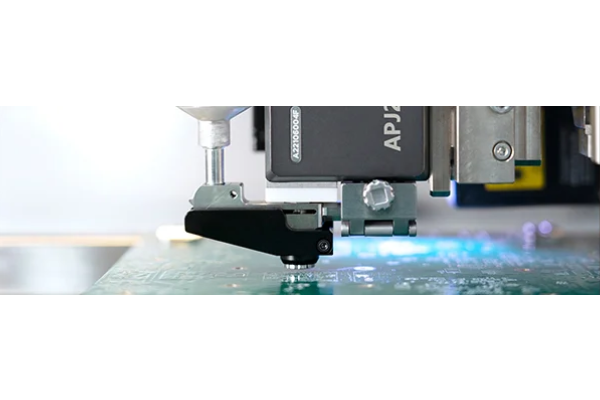

In electronics manufacturing, precise solder paste application is crucial for product reliability. Leading companies like Apple and Samsung have adopted jetting technology to streamline their assembly processes, resulting in improved efficiency and reduced costs.The automotive industry has also seen significant gains; manufacturers report enhanced adhesion quality when utilizing jetting valves for component assembly. For example, one automotive manufacturer experienced a marked improvement in adhesive bonding strength by integrating Axxon Mycronic jetting valves into their production line.

Furthermore, in medical device production, precision is not just advantageous but often a regulatory requirement. The use of Axxon Mycronic jetting valves ensures compliance with stringent quality standards while enhancing production efficiency. This capability is particularly important in an industry where product failures can have serious consequences.

Market analysis reports from organizations such as MarketsandMarkets and Grand View Research corroborate the widespread adoption of jetting technology across these industries. These reports indicate consistent growth in demand for precision dispensing solutions within sectors that require high levels of accuracy and reliability.

How Do Jetting Valves Compare to Traditional Dispensing Methods?

As manufacturers seek ways to improve efficiency and reduce costs, comparing new technologies with traditional methods becomes essential. Understanding how Axxon Mycronic jetting valves stack up against conventional dispensing techniques can guide decision-making processes.

Jetting valves significantly reduce material waste compared to manual or syringe dispensing methods while also offering quicker setup times and enhanced flexibility for manufacturers.

When comparing jetting valves with traditional syringe dispensing systems, the advantages become clear. Traditional methods often involve manual labor or slower automated processes that can lead to inconsistencies and higher material waste rates. In contrast, Axxon Mycronic jetting valves deliver rapid material application with minimal waste—an essential factor when working with expensive materials like high-performance adhesives or specialty inks.Additionally, setup times are drastically reduced with jetting systems; switching between different materials can be accomplished within minutes rather than hours—a critical factor in today’s fast-paced manufacturing environments.

This flexibility allows manufacturers to respond quickly to changing demands without incurring significant downtime.Moreover, the precision offered by jetting valves enhances product quality by ensuring consistent application patterns and reducing defects caused by over- or under-dispensing materials. This level of control is often unattainable with traditional methods.

Industry benchmarks indicate that companies transitioning from traditional methods to advanced jetting systems report up to 50% reductions in setup times and material waste. These statistics highlight the tangible benefits that come with adopting modern dispensing technologies like those offered by Axxon Mycronic.

What Does the Future Hold for Jetting Technology?

As we look ahead, it’s crucial to consider the trends shaping the future of jetting technology and its implications for manufacturers worldwide.

Technological advancements such as smart nozzles equipped with sensors will allow real-time monitoring of flow rates and droplet sizes, enhancing performance further. Additionally, integrating these technologies with Industry 4.0 principles will enable manufacturers to optimize operations through data-driven decision-making.

The future of Axxon Mycronic jetting valves is promising as technological advancements continue to emerge. Innovations such as smart nozzles equipped with sensors could allow real-time monitoring of flow rates and droplet sizes—ensuring optimal performance at all times.Moreover, as industries increasingly embrace Industry 4.0 principles, integrating these dispensing technologies with IoT devices will enable manufacturers to optimize their operations further through data-driven decision-making.

This integration will facilitate predictive maintenance strategies that minimize downtime and enhance overall productivity.Sustainability is another key trend influencing future developments in jetting technology. As manufacturers face pressure to reduce their environmental impact, advancements that allow for more eco-friendly materials will likely gain traction. The ability of Axxon Mycronic jetting valves to minimize waste aligns well with sustainability goals across industries.

These projections align with findings from industry leaders who emphasize innovation and sustainability as critical factors shaping future manufacturing practices. Reports from organizations like McKinsey & Company highlight that companies investing in advanced manufacturing technologies are better positioned for long-term success.

Conclusion

In summary, Axxon Mycronic jetting valves represent a significant advancement in dispensing technology that offers unparalleled precision and efficiency across various industries. From electronics to automotive applications, these valves have proven their worth by enhancing production processes while reducing waste and costs.

As we move forward into an era defined by technological innovation and sustainability concerns, embracing such advanced solutions will be crucial for manufacturers aiming to stay competitive. The insights shared here underscore not only the current capabilities of Axxon Mycronic jetting valves but also hint at an exciting future filled with possibilities for improved manufacturing practices.

- Axxon Technologies Official Website – This provides an overview of Axxon Technologies, a leading provider of dispensing solutions, including their innovative coating systems and jetting technologies. It is beneficial for understanding the company’s capabilities and product offerings.

- AxxonSoft Video Management Software – While primarily focused on video management, AxxonSoft is part of the Axxon brand and showcases their technological innovations. This can provide insights into the broader application of Axxon technologies in different sectors.

- Coherix and Eastern Michigan University Partnership – This article discusses the future of dispensing system engineers and highlights advancements in dispensing technologies, including robotics and precision manufacturing, which are relevant to Axxon Mycronic jetting valves.