Overview of Jetting Valves and Their Importance in Precision Dispensing

Jetting valves are critical components in precision dispensing systems, particularly within the electronics manufacturing industry. They enable the accurate and efficient application of various materials, such as adhesives, solder pastes, and coatings, onto substrates. The significance of jetting valves lies in their ability to deliver controlled amounts of material with high precision, minimizing waste and ensuring quality in the final product. This precision is essential in high-volume manufacturing environments where even minor discrepancies can lead to significant issues in product performance and reliability.

The growth of the electronics sector has driven demand for advanced dispensing technologies. Jetting valves are favored for their speed and accuracy compared to traditional dispensing methods, such as needle valves or mechanical dispensers. They can handle a wide range of viscosities and materials, making them versatile for different applications, including semiconductor packaging, printed circuit board (PCB) assembly, and other electronic components.

Introduction to Axxon Mycronic as a Key Player in the Market

Axxon Mycronic has emerged as a leading player in the precision dispensing market since its acquisition by Mycronic AB in 2016. Axxon specializes in high-volume dispensing solutions tailored for the electronics industry, boasting a remarkable compound annual growth rate (CAGR) of 39% in net sales. This growth trajectory has positioned Axxon as a market leader, particularly noted for its innovative dispensing technologies that enhance production efficiency and quality 1.

The company operates largely independently within China, developing its own intellectual property (IP) and conducting research and development (R&D) activities. This autonomy has allowed Axxon to adapt swiftly to market demands and technological advancements. Recently, Mycronic announced plans to explore a potential listing for Axxon on the STAR market of the Shanghai stock exchange, which would further solidify its brand presence and leadership position both domestically and globally.

Axxon’s commitment to innovation and sustainability aligns with broader trends in the electronics manufacturing sector, where there is an increasing emphasis on automation and reliability. As part of this dynamic landscape, Axxon continues to invest in R&D to meet the evolving needs of its customers across various applications, including automotive, medical devices, and industrial sectors.

Jetting valves play a crucial role in precision dispensing applications within electronics manufacturing, while Axxon Mycronic stands out as a key player driving advancements in this field through innovative solutions and strategic growth initiatives.

How Axxon Mycronic Jetting Valves Work

Mechanism of Operation

Detailed Explanation of the Jetting Process

The jetting process involves the precise and controlled dispensing of fluids through a nozzle without direct contact with the substrate. This method is particularly advantageous in applications requiring high accuracy and minimal material waste. The operation typically follows these steps:

- Fluid Preparation: The fluid is housed in a reservoir, often under pressure, to facilitate smooth dispensing.

- Actuation: When a dispensing command is initiated, an actuator (either pneumatic or electric) triggers the valve mechanism.

- Jetting Action: The actuator opens the valve, allowing the fluid to be forced through the nozzle. Depending on the system, this can occur rapidly—often in less than 1 millisecond—enabling high-frequency dispensing (up to 270 Hz) of small volumes (as low as 0.5 nL) .

- Dispensing Patterns: The fluid can be dispensed in various forms such as dots, beads, or lines, depending on the application requirements and nozzle design.

- Post-Dispensing Control: After the fluid is dispensed, the actuator closes the valve to prevent dripping and ensure clean application.

Types of Actuation Used

Jetting valves utilize different actuation methods, each offering distinct advantages:

- Pneumatic Actuation: This method uses compressed air to operate the valve. Pneumatic actuators are known for their speed and reliability, making them suitable for high-frequency applications. They can handle a wide range of viscosities and are commonly used in systems like the Liquidyn P-Dot series jetting valves .

- Electric Actuation: Electric actuators use electrical signals to control valve movement. They provide precise control over dispensing parameters and are often integrated with advanced control systems for enhanced performance. Electric actuation is particularly beneficial for applications requiring consistent performance over time .

- Piezoelectric Actuation: This technology employs piezoelectric materials that change shape when an electric field is applied, allowing for very rapid and precise fluid dispensing at micro-scale volumes. This method is ideal for applications needing ultra-fine control over material deposition.

Control Systems and User Interface for Operation

Modern jetting systems are equipped with sophisticated control systems that enhance usability and precision:

- Dedicated Controllers: Many jetting valves come with specific controllers designed to manage dispensing parameters effectively. For example, the JV200 controller allows users to set up dispensing speeds, volumes, and patterns via a user-friendly touchscreen interface .

- Programmable Logic Controllers (PLC): Some systems can be integrated with PLCs for more complex automation needs, enabling real-time adjustments based on production requirements .

- User Interfaces: The interfaces typically feature touchscreens that provide intuitive access to settings such as dispensing time, frequency, and volume control. These interfaces may also include diagnostic tools to monitor performance and troubleshoot issues.

Jetting valves operate through a highly controlled process involving various actuation methods that cater to different application needs. The integration of advanced control systems and user-friendly interfaces significantly enhances operational efficiency and precision in dispensing applications across various industries.

Key Features of Axxon Mycronic Jetting Valves

Components of Axxon Mycronic Jetting Valves

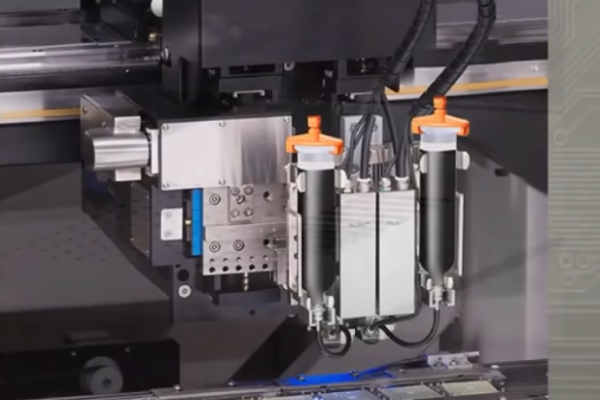

Axxon Mycronic jetting valves, such as the APJ1500, APJ2000, and APJ3000, are designed with several key components that enhance their functionality and versatility in precision dispensing applications:

- Nozzles: The valves feature interchangeable nozzles that allow for customization based on the application requirements. Different nozzle sizes (e.g., 50 µm, 75 µm, and 100 µm) enable precise control over droplet size and dispensing patterns, accommodating various fluid viscosities and application needs .

- Reservoirs: The jetting valves are equipped with fluid reservoirs that hold the materials to be dispensed. These reservoirs can handle a range of fluid types, including adhesives, solder pastes, and coatings, ensuring compatibility with diverse manufacturing processes .

- Actuation Mechanism: Axxon Mycronic valves utilize piezoelectric actuation for rapid and precise dispensing. This mechanism enables high-speed operation while maintaining accuracy in droplet formation, minimizing waste and improving efficiency.

Adjustability for Different Applications

Axxon Mycronic jetting valves are highly adjustable, making them suitable for a wide range of applications:

- Droplet Size: The valves can dispense droplets as small as 0.2 mm in diameter, with capabilities to achieve even smaller sizes (down to 0.14 mm) for specific materials. This adjustability is crucial for applications requiring fine detail and precision .

- Frequency: The jetting valves can operate at frequencies up to 1000 Hz, allowing for rapid dispensing cycles. This high-frequency capability significantly increases throughput compared to traditional dispensing methods, which is essential in fast-paced production environments .

- Viscosity Handling: These valves are designed to accommodate a broad range of fluid viscosities, from low-viscosity liquids to highly viscous materials (up to 200,000 cps). This versatility enables their use across various industries, including electronics manufacturing, automotive assembly, and medical device production .

- Temperature Control: Certain models, like the APJ3000, feature temperature control mechanisms that allow for the dispensing of thermally activated materials. This capability is particularly important for applications involving hot melts or waxes that require specific temperature conditions to achieve optimal viscosity.

Axxon Mycronic jetting valves are equipped with advanced components and offer significant adjustability in droplet size, frequency, viscosity handling, and temperature control. These features make them indispensable tools in modern manufacturing processes where precision and efficiency are paramount.

Applications Across Industries for Axxon Mycronic Jetting Valves

Role of Jetting Valves in Electronics Manufacturing

Jetting valves play a crucial role in the electronics manufacturing sector, particularly in PCB assembly, solder paste dispensing, and component placement. Their advanced dispensing capabilities enhance efficiency, precision, and reliability in various applications.

PCB Assembly

In PCB assembly, jetting valves are utilized for the precise application of adhesives, sealants, and coatings. Their non-contact dispensing method eliminates the need for Z-axis movement, allowing for high-speed operation and reduced cycle times. This is particularly beneficial for assembling complex PCBs with varying heights and irregular surfaces, where traditional contact dispensing methods may struggle to maintain accuracy.

- Advantages:

- High-Speed Dispensing: Jetting valves can operate at speeds of up to 3000 Hz, enabling rapid application of materials. This speed is essential in high-volume production environments where time efficiency is critical.

- Precision Control: The ability to dispense micro-deposits (as small as 0.5 nL) ensures that the right amount of adhesive or sealant is applied to each component without excess material waste.

Solder Paste Dispensing

Jetting valves are also extensively used for solder paste dispensing in electronics manufacturing. They allow for accurate placement of solder paste onto PCB pads, which is vital for ensuring reliable electrical connections.

- Key Features:

- Non-Contact Dispensing: This feature minimizes the risk of damaging delicate components during the dispensing process. The jetting action allows for consistent application even on uneven surfaces and within tight spaces.

- Versatility with Viscosities: Jetting valves can handle a wide range of solder paste viscosities (up to 200,000 cps), making them suitable for various formulations used in different electronic applications.

Component Placement

In addition to dispensing adhesives and solder pastes, jetting valves facilitate the accurate placement of electronic components. By integrating jetting technology into automated assembly lines, manufacturers can achieve higher levels of precision and consistency.

- Enhanced Flexibility: Jetting valves can dispense materials onto components with complex geometries or varying orientations without requiring physical contact. This capability is particularly useful for modern electronic devices that often feature intricate designs.

- Reduced Downtime: The quick setup and adjustment capabilities of jetting systems contribute to lower downtime during production runs. Operators can easily modify parameters such as droplet size and frequency to accommodate different components or materials as needed.

Axxon Mycronic jetting valves significantly enhance the efficiency and precision of electronics manufacturing processes. Their roles in PCB assembly, solder paste dispensing, and component placement highlight their importance in meeting the demands of modern production environments where speed, accuracy, and reliability are paramount. The ability to dispense a variety of materials with minimal waste further solidifies their position as essential tools in the electronics industry.

Applications of Jetting Valves in the Automotive Industry

Jetting valves, particularly those developed by Axxon Mycronic, play a vital role in the automotive industry, facilitating various processes such as adhesive dispensing, sealant application, and assembly operations. Their precision and efficiency make them indispensable in modern automotive manufacturing.

Adhesive Dispensing

Jetting valves are extensively used for dispensing adhesives in automotive applications. These valves enable the precise application of various adhesive types, including structural adhesives, which are essential for bonding components together.

- High Precision: Jetting valves can dispense micro-deposits as small as 0.5 nL, allowing for accurate placement on intricate parts without excess material waste. This precision is crucial in automotive manufacturing where components must fit together perfectly to ensure structural integrity.

- Speed and Efficiency: With operational speeds of up to 3000 Hz, jetting valves can quickly apply adhesives across multiple components, significantly reducing cycle times in production lines. This capability is essential for maintaining high throughput in automotive assembly.

Sealant Application

In addition to adhesives, jetting valves are ideal for applying sealants that protect against moisture and environmental damage. These sealants are critical in ensuring the longevity and reliability of automotive components.

- Non-Contact Dispensing: The non-contact nature of jetting valves minimizes the risk of damaging sensitive components during the sealing process. This feature allows for consistent application on various surfaces, including those with irregular geometries.

- Versatility with Materials: Jetting valves can handle a wide range of sealant viscosities (up to 2,000,000 mPa.s), making them suitable for both low and high-viscosity materials. This versatility is important for adapting to different sealing requirements across various vehicle models.

Assembly Processes

Jetting valves also contribute significantly to assembly processes within automotive manufacturing. They facilitate the accurate placement of components and materials that require precise dispensing.

- Component Placement: Jetting technology allows for the accurate dispensing of materials onto components that need to be assembled, such as sensors and electronic modules. The ability to dispense into tight spaces and complex geometries enhances assembly efficiency.

- Integration with Automation: These valves can be easily integrated into automated assembly lines, allowing for seamless operation alongside robotics and other automated systems. This integration supports high-speed production while maintaining quality control.

Axxon Mycronic jetting valves are integral to the automotive industry, providing advanced solutions for adhesive dispensing, sealant application, and assembly processes. Their high precision, speed, and versatility enable manufacturers to enhance productivity while ensuring the quality and reliability of automotive components. As vehicles become more complex with advanced technologies, the role of jetting valves will continue to grow in importance within the automotive manufacturing landscape.

Applications of Jetting Valves in Medical Devices

Jetting valves, particularly those developed by Axxon Mycronic, are essential in the medical device industry for precision assembly and fluid dispensing. Their ability to deliver controlled amounts of materials with high accuracy makes them indispensable in the manufacturing of various medical devices.

Precision Assembly

In the assembly of medical devices, jetting valves facilitate the precise application of adhesives and sealants that are critical for ensuring the functionality and safety of the devices.

- Adhesive Application: Jetting valves are used to dispense biocompatible adhesives in applications such as assembling catheters, syringes, and diagnostic equipment. The precision offered by these valves ensures that the right amount of adhesive is applied, preventing excess that could lead to product failure or contamination.

- Component Bonding: In devices like insulin pumps and inhalers, jetting valves allow for accurate bonding of components, ensuring that they fit together securely without compromising performance. This precision is vital in maintaining the integrity and reliability of life-saving devices.

Fluid Dispensing

Jetting valves excel in dispensing various fluids used in medical devices, including medications, coatings, and lubricants.

- Medication Dispensing: In drug delivery systems such as auto-injectors and pen injectors, jetting valves provide precise dosing of medications. This capability is crucial for ensuring that patients receive accurate dosages, enhancing treatment efficacy and safety.

- Coating Application: Jetting technology is also employed for applying protective coatings on medical devices. These coatings can enhance biocompatibility and reduce friction, which is essential for devices that interact with biological tissues.

Benefits of Jetting Valves in Medical Device Manufacturing

- High Precision: The ability to dispense very small volumes (as low as 0.5 nL) with high accuracy minimizes waste and ensures that each device meets stringent quality standards.

- Non-Contact Dispensing: This feature reduces the risk of contamination during the manufacturing process, which is critical in producing safe medical devices that comply with regulatory requirements.

- Versatility: Jetting valves can handle a wide range of viscosities and materials, making them suitable for various applications within the medical device sector. This versatility allows manufacturers to adapt quickly to changing product designs or requirements.

- Integration with Automation: These valves can be easily integrated into automated assembly lines, improving production efficiency while maintaining high standards of quality control.

Axxon Mycronic jetting valves play a vital role in the precision assembly and fluid dispensing processes within the medical device industry. Their high accuracy, non-contact dispensing capabilities, and versatility make them essential tools for manufacturers aiming to produce reliable and safe medical devices. As technology advances and new materials are developed, the importance of jetting valves in this sector is expected to grow even further.

Applications of Jetting Valves in Packaging

Jetting valves are increasingly utilized in various packaging processes, including labeling, sealing, and other applications that require precise material deposition. Their non-contact dispensing capabilities and high-speed operation make them ideal for modern packaging solutions.

Labeling

In the packaging industry, jetting valves can be employed for the precise application of labels and adhesive materials. The ability to dispense small amounts of adhesive accurately allows for efficient labeling processes without the risk of excess material or misalignment.

- High Precision: Jetting valves can dispense adhesives in very small volumes (less than 1 μl), ensuring that labels are securely attached without overflow or spillage, which can lead to waste and increased production costs.

- Speed: With operational speeds up to 3000 Hz, jetting valves enable rapid application of adhesives, significantly enhancing throughput in high-volume packaging environments.

Sealing

Jetting valves are also effective in sealing applications, where they dispense sealants that protect products from moisture and contamination. This is particularly important for food packaging and pharmaceuticals, where product integrity is critical.

- Non-Contact Dispensing: The non-contact nature of jetting minimizes the risk of damaging sensitive packaging materials. This feature allows for consistent application even on irregular surfaces or complex geometries.

- Versatility: Jetting valves can handle a wide range of sealant viscosities, making them suitable for various materials used in different packaging applications.

Other Packaging Processes

Beyond labeling and sealing, jetting valves find applications in several other packaging processes:

- Encapsulation: Jetting technology is used for encapsulating sensitive components in packaging materials, providing protection against environmental factors while maintaining product visibility.

- Conformal Coating: In electronic packaging, jetting valves are employed to apply conformal coatings that protect circuit boards from moisture and dust.

- Glob-Top Encapsulation: Jetting valves offer a precise method for applying glob-tops over sensitive electronic components, ensuring reliable protection without excess material.

Advantages of Jetting Valves in Packaging

- Consistency and Repeatability: Jetting valves provide accurate and repeatable material deposition, which is essential for maintaining quality standards in packaging.

- Reduced Waste: The precise control over droplet size and placement minimizes material waste, contributing to more sustainable manufacturing practices.

- Adaptability: Jetting systems can be easily integrated into existing production lines and adapted to various packaging requirements, enhancing operational flexibility.

Jetting valves play a significant role in the packaging industry by facilitating precise labeling, sealing, and other critical processes. Their ability to dispense materials accurately and rapidly makes them invaluable tools for manufacturers looking to enhance efficiency and product quality while minimizing waste. As the demand for automation and precision in packaging continues to grow, the use of jetting technology is expected to expand further across various sectors.

Suppliers and Pricing Information

Key Suppliers for Axxon Mycronic Jetting Valves

Axxon Mycronic jetting valves are supplied by various reputable manufacturers and distributors, both directly and through online marketplaces. Here is a list of notable suppliers:

Direct Manufacturers

- Axxon Mycronic

- As the original manufacturer, Axxon Mycronic offers a range of jetting valves, including the APJ1500, APJ2000, and APJ3000. They provide comprehensive support and documentation for their products.

- Website: Axxon – Mycronic

- SMTCOMPONENTS CO., LIMITED

- SMTCOMPONENTS CO., LIMITED provides a variety of dispensing solutions, including jetting valves that are designed for high precision and efficiency in applications such as electronics manufacturing and automotive assembly.

- Website: SMTCOMPONENTS CO., LIMITED

Online Marketplaces and Distributors

- SMT Components

- SMT Components specializes in supplying Axxon Mycronic parts, including various models of piezo jetting valves and spare parts for maintenance.

- Website: SMT Components

These suppliers offer a comprehensive range of Axxon Mycronic jetting valves and related products, catering to various industries such as electronics, automotive, and medical device manufacturing. Whether through direct purchase from manufacturers or via specialized distributors, customers can find the necessary components to enhance their dispensing processes.

Pricing Overview for Axxon Mycronic Jetting Valves

General Pricing Range

The pricing for Axxon Mycronic jetting valves varies based on the model and specifications, typically ranging from $11,000 to $32,000 per unit. Specific models, such as the APJ1500 and APJ2000, may fall within this range depending on features and configurations. More advanced models or those with specialized capabilities may command higher prices.

Factors Influencing Pricing

Several factors influence the pricing of Axxon Mycronic jetting valves:

- Model: Different models offer varying features and capabilities. For example, the APJ1500 is designed for high-speed applications, while the APJ1000S focuses on precision dispensing. The complexity and technology of each model can significantly affect its price.

- Features: Additional features such as advanced vision systems, multi-fluid capabilities, and customizable settings can increase the cost. Valves equipped with enhanced control systems or those capable of handling a wider range of viscosities typically have higher prices.

- Accessories: The inclusion of accessories such as specialized nozzles, reservoirs, or maintenance kits can also impact the overall cost. Customization options for specific applications may lead to additional expenses.

- Volume Discounts: Bulk purchases or long-term contracts can lead to reduced pricing per unit. Companies that require multiple valves for large-scale operations may negotiate better rates.

- Market Conditions: Fluctuations in supply chain costs, demand in the electronics and manufacturing sectors, and technological advancements can also affect pricing trends over time.

Axxon Mycronic jetting valves offer a range of pricing influenced by model specifications, features, accessories, and market conditions. Understanding these factors can help businesses make informed purchasing decisions that align with their operational needs and budget constraints.

Availability of Axxon Mycronic Jetting Valve Models

Commonly Available Models and Their Specifications

Axxon Mycronic offers several models of jetting valves, each designed for specific applications within various industries. Here are some of the commonly available models along with their key specifications:

- APJ1500

- Maximum Frequency: 0-1000 Hz

- Maximum Fluid Pressure: 0-0.3 MPa

- Minimum Dot Diameter: 0.2 mm (can achieve down to 0.14 mm for specific epoxies)

- Applicable Fluid Viscosity: 1-200,000 cps

- Dimensions: 117 × 25.4 × 76 mm

- Weight: 440 g

- Maximum Nozzle Heating Temperature: 200°C

- Applications: Suitable for high-speed dispensing in electronics manufacturing, automotive assembly, and medical devices.

- APJ1000S

- Maximum Frequency: Up to 500 Hz

- Minimum Droplet Size: 2 nL

- Fluid Compatibility: Works with adhesives, sealants, and conductive pastes.

- Applications: Ideal for underfill, dam & fill processes, and precision coating in electronics packaging.

- APJ3000

- Advanced Features: Equipped with a vision system for alignment and inspection.

- Multi-Fluid Capability: Can handle a variety of materials including adhesives and coatings.

- Applications: Designed for high precision in both small-scale prototyping and large-scale manufacturing.

Tips for Sourcing and Ordering

When sourcing and ordering Axxon Mycronic jetting valves, consider the following tips:

- Identify Specific Needs: Determine the specific application requirements such as fluid type, viscosity, and required precision to select the appropriate model.

- Contact Distributors: Reach out to distributors or the manufacturer directly to ensure you receive genuine products and support. Suppliers like SMT Components and Mycronic itself offer detailed product information and customer support.

- Request Quotes for Bulk Orders: If you require multiple units or additional accessories, request quotes to explore potential discounts or bundled pricing options.

- Inquire About Lead Times: Check the availability of the desired model and inquire about lead times for delivery, especially if you have tight production schedules.

- Consider Accessories and Maintenance Kits: When ordering, consider any necessary accessories or maintenance kits that may enhance the functionality or longevity of the jetting valves.

- Evaluate Support Services: Look into the support services offered by suppliers, including installation assistance, training, and maintenance options, which can be crucial for optimizing the use of jetting valves in production environments.

By following these tips, you can effectively source Axxon Mycronic jetting valves tailored to your operational needs while ensuring quality and support throughout the purchasing process.

Identifying Specific Requirements

Flow Rate Considerations

Importance of Selecting the Right Flow Rate for Different Materials

Selecting the appropriate flow rate is crucial in various industrial applications, particularly when dealing with different materials. The flow rate refers to the volume of fluid passing through a specific point per unit of time and can significantly impact the efficiency, quality, and safety of processes. Here are key reasons why selecting the right flow rate is important:

- Material Characteristics: Different materials, such as adhesives, sealants, or coatings, have unique viscosities and flow behaviors. For instance, low-viscosity fluids can be dispensed at higher flow rates without compromising quality, while high-viscosity materials require slower flow rates to ensure proper application and adhesion.

- Process Efficiency: An optimal flow rate ensures that materials are applied consistently and uniformly, reducing waste and improving overall efficiency. Too high a flow rate can lead to oversaturation or spillage, while too low a flow rate may result in incomplete coverage or insufficient bonding.

- Quality Control: Maintaining a consistent flow rate is essential for achieving desired product specifications. Variations in flow rates can lead to defects in products, such as weak bonds in adhesive applications or uneven coatings.

- Safety Considerations: In certain applications, such as pharmaceuticals or food processing, selecting the correct flow rate is vital to prevent contamination or ensure compliance with regulatory standards. Inadequate flow rates can also lead to pressure build-up or equipment failure.

Examples of Applications Requiring Specific Flow Rates

- Adhesive Dispensing in Electronics Manufacturing:

- Flow Rate Requirement: Typically between 0.5 to 2 mL/min for precise application.

- Reason: Ensures accurate placement of adhesives on PCBs without excess material that could interfere with component placement.

- Solder Paste Application:

- Flow Rate Requirement: Generally around 1 to 3 mL/min depending on the viscosity of the solder paste.

- Reason: A controlled flow rate is necessary to achieve uniform application on solder pads for reliable electrical connections.

- Sealant Application in Automotive Assembly:

- Flow Rate Requirement: Can range from 0.1 to 5 mL/min based on the type of sealant used.

- Reason: Precise control of flow rates is critical to ensure effective sealing without overflow that could damage surrounding components.

- Fluid Dispensing in Medical Devices:

- Flow Rate Requirement: Often less than 0.5 mL/min for precise dosing in drug delivery systems.

- Reason: Accurate dosing is essential for patient safety and treatment efficacy; incorrect flow rates can lead to underdosing or overdosing.

- Food and Beverage Industry:

- Flow Rate Requirement: Varies widely; for example, sauces may require a flow rate of 2-10 mL/min depending on viscosity.

- Reason: Consistent application ensures product quality and prevents waste during packaging processes.

selecting the right flow rate for different materials is critical for optimizing process efficiency, ensuring product quality, and maintaining safety standards across various industries. Understanding the specific requirements of each application helps manufacturers achieve consistent results while minimizing waste and potential defects.

Viscosity Handling

Challenges with High-Viscosity Materials

High-viscosity materials present several challenges in manufacturing and dispensing processes, primarily due to their resistance to flow and unique physical properties. Some of the key challenges include:

- Flow Resistance: High-viscosity fluids exhibit significant internal friction, making them difficult to pump or dispense. This resistance can lead to inconsistent flow rates and difficulties in maintaining a steady dispensing operation.

- Cavitation Issues: When attempting to pump high-viscosity materials, cavitation can occur, which disrupts flow and can damage equipment. This is particularly problematic in systems not designed to handle such materials.

- Heat Generation: The energy required to move high-viscosity fluids often results in heat buildup, which can further increase viscosity and complicate the dispensing process. Excessive heat can lead to material degradation or changes in properties.

- Mixing Challenges: Achieving homogeneity in high-viscosity mixtures is difficult due to localized mixing and dead spots within mixing vessels. This can result in uneven distribution of components, particularly critical in pharmaceutical applications where uniformity is essential.

- Increased Cycle Times: The need for slower dispensing rates or additional mixing time can significantly lengthen production cycles, impacting overall efficiency and throughput.

Solutions Offered by Axxon Mycronic Valves for Viscosity Management

Axxon Mycronic jetting valves are specifically designed to address the challenges associated with high-viscosity materials through several innovative features:

- Pneumatic and Piezoelectric Actuation: Axxon Mycronic valves utilize advanced actuation methods that provide consistent force and control over the dispensing process, allowing for effective handling of high-viscosity fluids without cavitation issues. The precise control helps maintain steady flow rates even with thicker materials.

- Adjustable Flow Rates: The valves allow operators to adjust flow rates according to the viscosity of the material being dispensed. This flexibility ensures that the right amount of material is applied without excess, minimizing waste and improving efficiency.

- Non-Contact Dispensing Technology: The non-contact nature of jetting valves reduces the risk of damaging sensitive materials during application. This feature is particularly beneficial when working with high-viscosity adhesives and sealants that require careful handling.

- Temperature Control Options: Some models come equipped with heating capabilities that allow operators to manage the viscosity of materials by adjusting their temperature before dispensing. Heating reduces viscosity, facilitating easier flow and application.

- High Precision and Speed: Axxon Mycronic jetting valves are capable of high-speed operation (up to 3000 Hz), enabling rapid dispensing cycles even for viscous materials. This capability helps reduce overall cycle times while maintaining accuracy in application.

- Versatile Material Compatibility: These valves can handle a wide range of viscosities (up to 2,000,000 mPa.s), making them suitable for various applications across industries such as automotive, electronics, and medical devices.

Handling high-viscosity materials poses significant challenges in manufacturing processes, including flow resistance, cavitation issues, heat generation, and increased cycle times. Axxon Mycronic jetting valves provide effective solutions through advanced actuation methods, adjustable flow rates, non-contact dispensing technology, temperature control options, high precision, and versatility in material compatibility. These features enable manufacturers to optimize their processes while ensuring quality and efficiency when working with challenging viscous materials.

Addressing Application-Specific Challenges in Various Industries

Common Challenges Faced in Various Industries

Different industries encounter unique challenges that can hinder production efficiency, product quality, and overall operational success. Here are some common challenges across sectors:

- Electronics Manufacturing:

- Rapid Technological Advancements: Keeping pace with fast-evolving technology and short product life cycles can lead to increased costs and waste.

- Component Shortages: Supply chain disruptions can result in delays and increased prices for essential components.

- Quality Control Issues: The complexity of electronic devices increases the potential for defects during manufacturing.

- Automotive Industry:

- Regulatory Compliance: Manufacturers must navigate stringent safety and environmental regulations, which can complicate production processes.

- Cost Management: Intense competition leads to pressure on pricing, requiring manufacturers to optimize production costs without sacrificing quality.

- Supply Chain Vulnerabilities: Global supply chain disruptions can impact the availability of critical components.

- Medical Device Manufacturing:

- Biocompatibility Requirements: Ensuring that materials used in devices meet strict biocompatibility standards is crucial for patient safety.

- Precision in Assembly: High precision is required for assembling intricate medical devices, where even minor errors can have significant consequences.

- Regulatory Challenges: Compliance with rigorous regulatory standards (e.g., FDA) can slow down the development process.

- Packaging Industry:

- Sustainability Concerns: Increasing pressure to adopt environmentally friendly practices while maintaining cost-effectiveness.

- Customization Needs: The demand for personalized packaging solutions requires flexibility in manufacturing processes.

- Efficiency in Production: Balancing speed and quality in packaging processes is essential to meet consumer demands.

How Axxon Mycronic Jetting Valves Can Provide Solutions

Axxon Mycronic jetting valves offer innovative solutions to address these application-specific challenges across various industries:

- Enhanced Precision and Control:

- Jetting valves provide high-precision dispensing capabilities, which are essential in electronics and medical device manufacturing. This precision helps reduce defects and ensures compliance with stringent quality standards.

- Versatility with Material Handling:

- Axxon Mycronic valves can handle a wide range of viscosities, making them suitable for various applications, from low-viscosity adhesives to high-viscosity sealants. This versatility allows manufacturers to adapt quickly to changing material requirements.

- Non-Contact Dispensing Technology:

- The non-contact nature of jetting valves minimizes the risk of component damage during dispensing, which is particularly beneficial in sensitive applications such as electronics assembly and medical device manufacturing.

- High-Speed Operation:

- With operational speeds up to 3000 Hz, Axxon Mycronic jetting valves enable rapid dispensing cycles, enhancing production efficiency and reducing cycle times across industries like automotive and packaging.

- Temperature Control Options:

- Some models come equipped with heating capabilities that allow operators to manage the viscosity of materials by adjusting their temperature before dispensing. This feature is particularly useful for high-viscosity materials that require heating for optimal flow.

- Integration with Automation Systems:

- Axxon Mycronic jetting valves can be integrated into automated production lines, providing flexibility and scalability while ensuring consistent quality across high-volume manufacturing processes.

- Sustainability Practices:

- By minimizing material waste through precise dispensing, these valves contribute to more sustainable manufacturing practices, addressing environmental concerns within the packaging industry.

Various industries face specific challenges that can impact their operational efficiency and product quality. Axxon Mycronic jetting valves provide effective solutions through enhanced precision, versatility, non-contact technology, high-speed operation, temperature control options, automation integration, and support for sustainability practices. By leveraging these advanced dispensing technologies, manufacturers can address application-specific challenges effectively and maintain a competitive edge in their respective markets.

Conclusion

Summary of Axxon Mycronic Jetting Valves’ Capabilities and Applications

Capabilities

Axxon Mycronic jetting valves, particularly the APJ1500 and APJ1000S models, are designed to meet the demands of modern manufacturing with advanced dispensing technology. Key capabilities include:

- High-Speed Jetting: The APJ1500 can achieve jetting speeds of up to 1,000 dots per second, significantly faster than traditional methods. This high throughput is essential for meeting the production demands in high-volume environments.

- Precision Control: These valves can dispense droplets as small as 1 nanoliter, ensuring accurate material placement, which is critical in applications requiring meticulous assembly and coating.

- Flexibility and Non-Contact Dispensing: The non-contact feature allows for dispensing without physical contact with components, making it suitable for complex assemblies and sensitive materials.

- Viscosity Handling: Axxon Mycronic valves can accommodate a wide range of fluid viscosities (from 1 to 200,000 cps), allowing them to handle everything from low-viscosity inks to high-viscosity adhesives.

- Temperature Control: Integrated temperature control mechanisms help maintain consistent viscosity during dispensing, which is crucial for achieving reliable results.

- Minimal Maintenance: Designed for longevity, these valves require minimal maintenance due to their robust construction and quick-release features for easy servicing.

Applications

Axxon Mycronic jetting valves are versatile and find applications across various industries:

- Electronics Manufacturing: Used for solder paste application, underfill processes, and encapsulation. Their precision ensures reliable bonding and protection of delicate components.

- Automotive Industry: Ideal for adhesive dispensing in structural bonding applications where durability under varying environmental conditions is essential.

- Medical Device Assembly: Their accuracy in dispensing biocompatible materials is critical for assembling sensitive medical devices where exact material placement is vital.

- Packaging Industry: Effective in labeling and sealing processes, ensuring that adhesives are applied accurately without excess material.

- Optics and MEMS: Suitable for precision coating and encapsulation of optical components, ensuring uniform application thickness.

Final Recommendations for Users Considering Axxon Mycronic Jetting Valves

- Assess Application Requirements: Before selecting a valve, evaluate the specific needs of your application, including the type of materials used, required precision, and production speed.

- Consider Model Features: Choose between models like the APJ1500 for high-speed applications or the APJ1000S for tasks requiring extreme precision based on your operational needs.

- Evaluate Material Compatibility: Ensure that the selected valve can handle the viscosities and types of fluids you plan to dispense. Axxon Mycronic valves are versatile but confirming compatibility is essential.

- Plan for Integration: Consider how the jetting valve will integrate into your existing production line or automation systems. Axxon Mycronic valves are designed for easy integration but assess any additional requirements that may arise.

- Seek Expert Consultation: Engage with Axxon Mycronic representatives or authorized distributors to get insights into the best solutions tailored to your specific challenges and operational goals.

- Invest in Training and Support: Ensure that your team receives adequate training on operating and maintaining the jetting valves to maximize their efficiency and lifespan.

By following these recommendations, users can effectively leverage Axxon Mycronic jetting valves to enhance their manufacturing processes, improve product quality, and achieve operational efficiency across various applications.

FAQs about Axxon Mycronic Jetting Valves and Their Applications

1. What are Axxon Mycronic jetting valves?

Axxon Mycronic jetting valves are advanced dispensing solutions designed for high precision and efficiency in various manufacturing applications. They utilize piezoelectric technology to deliver controlled amounts of fluids, including adhesives, sealants, and coatings, without direct contact with the substrate.

What are the key features of Axxon Mycronic jetting valves?

- High-Speed Jetting: Capable of dispensing up to 1000 dots per second, significantly faster than traditional methods.

- Precision Control: Minimum droplet size can be as small as 0.2 mm, ensuring accurate material placement.

- Non-Contact Dispensing: Reduces the risk of damaging sensitive components by allowing materials to be jetted without physical contact.

- Versatility: Can handle a wide range of viscosities (up to 200,000 cps) and materials, including low-viscosity liquids and high-viscosity adhesives.

- Temperature Control: Integrated mechanisms for regulating temperature help maintain consistent viscosity and performance during dispensing.

3. What applications are suitable for Axxon Mycronic jetting valves?

Axxon Mycronic jetting valves are versatile and can be used in various applications, including:

- Electronics Manufacturing: For solder paste application, underfill processes, and encapsulation of components.

- Automotive Industry: In structural bonding and adhesive dispensing for components that must withstand harsh conditions.

- Medical Device Assembly: For precise dispensing of biocompatible materials in sensitive devices.

- Packaging: In labeling and sealing processes where accurate adhesive application is crucial.

4. How do I choose the right model of Axxon Mycronic jetting valve for my application?

When selecting a model, consider the following factors:

- Application Requirements: Identify the specific needs such as material type, viscosity, required precision, and production speed.

- Model Features: Evaluate models like the APJ1500 for high-speed applications or the APJ1000S for precision tasks based on your operational requirements.

- Compatibility with Materials: Ensure that the selected valve can handle the viscosities and types of fluids you plan to dispense.

5. What maintenance is required for Axxon Mycronic jetting valves?

Axxon Mycronic jetting valves are designed for minimal maintenance due to their robust construction. Key maintenance practices include:

- Regular cleaning of nozzles and fluid channels to prevent clogging.

- Periodic checks of temperature control systems to ensure consistent performance.

- Utilizing quick-release features for easy access during servicing.

6. Can Axxon Mycronic jetting valves be integrated into automated production lines?

Yes, Axxon Mycronic jetting valves are designed for easy integration into automated systems. Their compatibility with various controllers allows them to work seamlessly with existing manufacturing setups, enhancing production efficiency while maintaining high-quality standards.

7. What industries benefit from using Axxon Mycronic jetting valves?

Axxon Mycronic jetting valves are beneficial across multiple industries, including:

- Electronics

- Automotive

- Medical Devices

- Packaging

- Optics and MEMS

These industries require precision dispensing solutions that can adapt to various materials and production demands.

Conclusion

Axxon Mycronic jetting valves offer advanced capabilities that enhance efficiency and precision in various manufacturing applications. By understanding their features and applications, users can effectively leverage these technologies to meet their specific operational needs while ensuring high-quality output. For further inquiries or specific product details, users are encouraged to consult with SMTCOMPONENTS CO., LIMITED or will@smtcomponents.com