Understanding DEK Squeegees for Reduced Paste Smear is crucial for achieving high-quality SMT printing. These squeegees are designed to minimize paste smearing, ensuring cleaner prints and reducing defects. By learning about these tools, you can enhance your printing process, improve product quality, and reduce maintenance needs.

DEK Squeegees for Reduced Paste Smear offer several key benefits: they provide more consistent paste roll control, reduce cleaning frequency, feature optimized blade angles for minimal smear, and are compatible with various stencil types. These features collectively contribute to improved print quality and efficiency in SMT applications.

Table of Contents

- Why Are DEK Squeegees Essential for Consistent SMT Printing?

- Conclusion

- Frequently Asked Questions

1. Why Are DEK Squeegees Essential for Consistent SMT Printing?

As a printing process expert, I can confirm that DEK Squeegees for Reduced Paste Smear are crucial for maintaining consistent SMT printing quality. These squeegees are engineered to optimize paste transfer while minimizing defects, ensuring reliable and repeatable results in high-volume production environments.

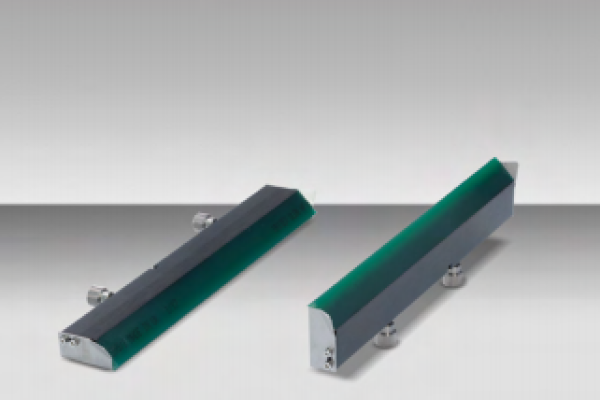

1.1 DEK Printer Polyurethane Bonded Squeegees Green 70-75 Shore Hardness ~ 45°

| SAP | DEK | Size | Unit |

| 03136509 | SQA248 | 100mm | Pair |

| 03130492 | SQA254 | 150mm | Pair |

| 03130403 | SQA161 | 170mm | Pair |

| 03130488 | SQA167 | 200mm | Pair |

| 03130406 | SQA174 | 250mm | Pair |

| 03130398 | SQA152 | 300mm | Pair |

| 03130408 | SQA185 | 350mm | Pair |

| 03142810 | SQA190 | 400mm | Pair |

| 03138030 | SQA201 | 440mm | Pair |

| 03130490 | SQA210 | 483mm | Pair |

| 03142818 | SQA219 | 510mm | Pair |

| 03141708 | SQA231 | 535mm | Pair |

1.2 Key Features

- Available in a hardness range up to 120 durometer

- Can be re-ground to maintain a sharp edge for the life of the squeegee

- High-quality material for durability and performance

- Satisfies multiple stencil printing application requirements

1.3 Advanced Implementation Strategy

DEK Squeegees for Reduced Paste Smear offer exceptional versatility with their wide range of durometer options. This allows manufacturers to select the optimal hardness for their specific application, whether it’s fine-pitch printing requiring softer blades or high-pressure applications benefiting from harder options up to 120 durometer.

One of the most significant advantages of DEK Squeegees for Reduced Paste Smear is their ability to be re-ground. This feature extends the life of the squeegee while maintaining a sharp edge, crucial for consistent paste deposition and reduced smearing. I recommend implementing a regular inspection and re-grinding schedule to maximize squeegee lifespan and print quality.

The high-quality materials used in DEK Squeegees for Reduced Paste Smear contribute to their durability and consistent performance. This reliability is essential in high-volume production environments where consistent print quality directly impacts overall yield and efficiency.

To optimize SMT printing consistency, I suggest utilizing DEK Squeegees for Reduced Paste Smear in conjunction with proper pressure settings and print speed adjustments. The squeegees’ ability to satisfy multiple stencil printing requirements makes them ideal for manufacturers dealing with diverse product lines or frequently changing production demands.

Claims:

- True: DEK Polyurethane squeegees can be used for single thickness or multi-level stencil applications, as well as adhesive stencils and mesh or emulsion screen printing.

- False: All DEK Squeegees require the same pressure settings; in fact, optimal pressure varies based on the squeegee durometer and specific application requirements.

2. Conclusion

DEK Squeegees for Reduced Paste Smear represent a significant advancement in SMT printing technology. Their durability up to 120 durometer and ability to be re-ground ensures consistent performance throughout their lifetime. The high-quality materials used in their construction, combined with advanced design features like electroformed E-squeegee designs, deliver superior paste control and minimal smearing. These squeegees satisfy diverse printing requirements while maintaining optimal print quality across various applications, making them an essential component for high-volume SMT manufacturing.

3. Frequently Asked Questions

1. How do DEK squeegees reduce paste smearing?

DEK squeegees utilize an optimized blade profile with a 60-degree primary angle that behaves like a 45-degree blade, combined with advanced materials that prevent paste from wicking up the blade face. This design enables clean wiping with pressures as low as 0.144 Kgms per centimeter1.

2. What pressure settings are recommended for optimal performance?

For conventional solder paste, use 500 grams of pressure per 25mm of squeegee blade. For lead-free applications, reduce pressure to around 300 grams per 25mm of blade length to achieve clean stencil wiping while preventing smearing2.

3. What print speeds should be used with DEK squeegees?

For standard applications, maintain speeds around 25mm per second. However, when printing lead-free solder paste, increase speeds to 50-100mm per second for optimal results and to prevent paste adhesion to the blades4.

4. How do DEK squeegees maintain consistent paste roll control?

DEK squeegees feature advanced designs that enable more consistent paste roll control through optimized blade angles and surface finishes. This results in reduced cleaning frequency and improved print quality across high-volume production runs3.

External links recommendation:

- ASMPT Official Website – DEK Squeegee Blades

This resource provides detailed information on DEK squeegee blades designed to reduce paste smear, including specifications on blade materials, hardness, and angles optimized for SMT printing.

Source: ASMPT Official Website - SMT Components – DEK Squeegee Blades for Precision Printing

Explore a comprehensive guide on choosing the best DEK squeegee blades for precision printing, focusing on their ability to reduce paste smearing and improve print quality.

Source: SMT Components - Surface Mount Process – Solder Paste Printing Guide

This guide offers insights into the solder paste printing process, including recommended pressure settings and blade angles to minimize paste smearing and achieve optimal deposition.

Source: Surface Mount Process - IPC Technical Resources – Squeegee Blade Impact on Print Quality

Access technical studies on how different squeegee blade types and settings affect solder paste print quality, with a focus on reducing paste smear in SMT applications.

Source: IPC Technical Resources