As a printing process expert, I can confirm that DEK Squeegees for Minimal Wear and Tear are essential for maintaining consistent print quality while reducing maintenance costs. Understanding these components is crucial as they directly impact your production efficiency, print quality, and long-term equipment reliability through their advanced design and durable construction.

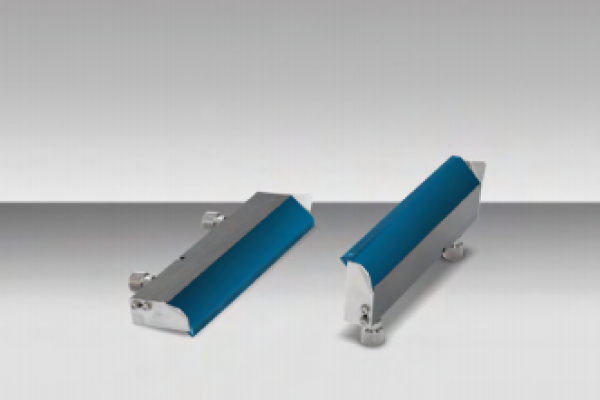

DEK Squeegees for Minimal Wear and Tear incorporate several key features: stainless steel construction for outstanding consistency, wider pressure windows for minimal wear, bonded assemblies for ultra-straight blade edges, and quick-change mechanisms that reduce setup time. These squeegees are available in both 60° and 45° angles with various overhang options to suit different applications.

Table of Contents

- How Do DEK Squeegees for Minimal Wear and Tear Enhance Production Longevity?

- Conclusion

- Frequently Asked Questions

1. How Do DEK Squeegees for Minimal Wear and Tear Enhance Production Longevity?

As a printing process expert, I can confirm that DEK Squeegees for Minimal Wear and Tear are engineered to maximize production longevity through advanced materials and innovative design features. These components significantly impact long-term equipment reliability and reduce maintenance requirements in high-volume manufacturing environments.

1.1 DEK Printer Polyurethane Bonded Squeegees Green 70-75 Shore Hardness ~ 60°

| SAP | DEK | Size | Unit |

| 03134708 | SQA260 | 100mm | Pair |

| 03130494 | SQA266 | 150mm | Pair |

| 03142810 | SQA119 | 170mm | Pair |

| 03131308 | SQA120 | 200mm | Pair |

| 03128791 | SQA139 | 250mm | Pair |

| 03130400 | SQA155 | 300mm | Pair |

| 03128789 | SQA121 | 350mm | Pair |

| 03130409 | SQA196 | 400mm | Pair |

| 03130391 | SQA122 | 440mm | Pair |

| 03131649 | SQA136 | 483mm | Pair |

| 03142819 | SQA225 | 510mm | Pair |

| 03138819 | SQA123 | 535mm | Pair |

1.2 Performance Features

- High-performance materials with stainless steel and polyurethane options

- Optimized blade design with 45° or 60° printing angles

- Quick-change mechanism reducing changeover time by 50%

- Consistent pressure control through advanced mounting systems

1.3 Advanced Implementation Strategy

DEK Squeegees for Minimal Wear and Tear utilize stainless steel construction that sustains higher squeegee pressures while maintaining outstanding consistency. This wider pressure window makes them ideal for boards featuring a mix of large and fine-pitch components, or where panel flatness cannot be assured.

For optimal longevity, I recommend implementing the DEK Squeegees for Minimal Wear and Tear with their innovative quick-change system. This design eliminates traditional thumbscrews, allowing single-step changeovers and preventing issues related to over-tightening or difficult removal.

The durability of DEK Squeegees for Minimal Wear and Tear is enhanced through polyurethane options available up to 120 durometer for single thickness stencils. These can be reground to maintain a keen edge throughout their lifetime, while bonded assemblies guarantee ultra-straight blade edges.

To maximize production longevity, I suggest utilizing the mechanical coding system that prevents incorrect squeegee insertion. This feature, combined with automated locking mechanisms, ensures consistent setup accuracy while maintaining production speed across multiple changeovers.

Claims:

- True: ASMPT DEK squeegees are designed to minimize wear and tear, enhancing production longevity by using high-quality materials, optimized blade geometry, and features like quick-change mechanisms, allowing for consistent paste deposition with minimal need for replacements, leading to increased uptime and reduced maintenance costs in the SMT printing process.

- False: All squeegee types require daily replacement; in fact, they are designed for extended use with proper maintenance and can be reground to maintain performance.

2. Conclusion

ASMPT DEK Squeegees for Minimal Wear and Tear significantly enhance production longevity through their advanced design and durable materials. The stainless steel construction allows for higher pressures and wider pressure windows, making them ideal for boards with mixed component sizes. Quick-change mechanisms reduce changeover time by up to 50%, while bonded assemblies guarantee ultra-straight blade edges. The ability to regrind polyurethane squeegees extends their lifespan, and optimized blade angles ensure consistent paste roll control. By minimizing wear, reducing maintenance, and improving print quality, these squeegees contribute to increased uptime and long-term production efficiency.

3. Frequently Asked Questions

1. What materials are used in DEK squeegees to ensure longevity?

DEK squeegees are available in both stainless steel and polyurethane options up to 120 durometer. The stainless steel versions sustain higher pressures while maintaining consistency, and polyurethane versions can be reground to maintain a keen edge throughout their lifetime13.

2. How does the quick-change system improve production efficiency?

The new quick-change holder eliminates thumbscrews and features automatic locking, reducing changeover time by up to 50%. A mechanical coding system prevents incorrect squeegee insertion, making the process faster and more reliable4.

3. What mounting options are available for minimal wear?

Two mounting options are available: bonded and clamped. Clamped mounting allows easy blade interchange and flexibility adjustment, while bonded mounting guarantees an ultra-straight blade edge and enables lower pressure settings35.

4. How do DEK squeegees maintain consistent performance over time?

DEK squeegees feature a wider pressure window that provides excellent consistency and minimal wear. For heterogeneous assemblies with mixed component sizes, they maintain performance even when panel flatness varies, ensuring long-term reliability2.

external links recommendation:

- ASM Squeegees – DEK Metal and Polyurethane Options

This document provides detailed information on DEK squeegees, including metal and polyurethane options designed for minimal wear and tear. It covers various angles and mounting options to suit different applications.

Source: ASM Squeegees - SMT Components – DEK Squeegee Blades

Explore a comprehensive line of DEK squeegee blades designed for precision printing, emphasizing their role in achieving consistent paste transfer and reducing wear through advanced material choices.

Source: SMT Components - Toptradeco – DEK Squeegee Specification Sheet

This datasheet outlines the specifications of DEK squeegees, focusing on their durability and performance features that contribute to minimal wear and tear in high-volume production environments.

Source: Toptradeco DEK Squeegees