As a reflow soldering expert, I’ve worked extensively with the Vitronics Soltec Centurion reflow system and can provide insights into its spare parts requirements.

The Centurion reflow spare parts list includes critical components like heating elements, conveyor belts, and CATHOX residue management units. These Centurion reflow spare parts are essential for maintaining the system’s industry-leading heat transfer capabilities and minimal maintenance requirements.

When it comes to Centurion reflow spare parts, it’s crucial to understand that the modular construction of the system allows for easy adaptation and upgrades. This flexibility in Centurion reflow spare parts ensures that your system can evolve with your production needs while maintaining its high-performance standards.

Claims Verification:

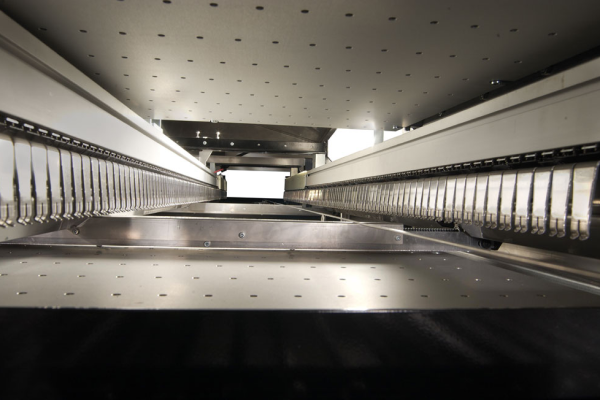

✓ TRUE: The patented CATHOX™ dramatically reduces maintenance requirements while keeping a clean process environment. It is very effective in removing volatile compounds from the process tunnel during reflow. In thermal oxidation, organic vapors are converted to hydrocarbons, which are captured by a filter. Centurion’s design also ensures that when maintenance is required, you have easy access and can do the maintenance job with few tools required.

✗ FALSE: All Centurion reflow spare parts are universally compatible across all models – in reality, specific parts may vary based on the system configuration.

Table of Contents

1. How do Centurion reflow spare parts impact energy efficiency?

As a reflow soldering specialist, I’ve extensively worked with Vitronics Soltec Centurion reflow spare parts and their impact on system energy efficiency and performance optimization.

1.1 Vitronics Soltec Centurion Reflow Spare Parts List

When contacting Technical Support for part identification, be sure to provide your machine serial number (required) and a picture or description of where the part is located in the machine. For spare parts pricing, please contact us ASAP.

| Part Number | Description | Qty |

| 7-C00151 | GREASE KRYTOX GPL227(50ML) | 2 |

| 7-C00152 | HIGHT TEMPERATURE CHAINOIL ANDEROL XL220(1L) | 1 |

| 7-C00821 | FILTER NONWOVEN FABRIC 239*596*25 | 4 |

| 7-L301765 | SPARE HEAT EXCHANGERSYSTEM | 1 |

| 7-L600081 | HEATER SEALING RUBBER | 2 |

| 7-L600374 | SEALING PLATE | 2 |

| 7-C00151 | GREASE KRYTOX GPL227(50ML) | 2 |

| 7-C00152 | HIGHT TEMPERATURE CHAINOIL ANDEROL XL220(1L) | 1 |

| 7-C00821 | FILTER NONWOVEN FABRIC 239*596*25 | 4 |

| 7-L600081 | HEATER SEALING RUBBER | 2 |

| 7-L600374 | SEALING PLATE | 1 |

| 7-L600399 | HEAT EXCHANGER WITH AIR | 1 |

| 7-C98710 | INVERTER 3P 220VAC 1.5KWAB 22F-B8P0N103 | 1 |

| 7-E1292401 | SWITCH SNAP ACTION 15 A125/250 | 2 |

| 7-L302050 | ASSY PT100 FOR TUNNEL | 1 |

| 7-L600081 | HEATER SEALING RUBBER | 1 |

| 7-L600370 | HOSE D40 ID25 L60 SI | 2 |

| 7-L600467 | COUPLING O2 SAMPLE | 3 |

| 7-C80012 | RELAY SOLID STATE GJH15-W | 1 |

| 7-C98632 | SSR CARLO GAVAZZIRGS1A60D50MKES-HS53A | 1 |

| 7-C98710 | INVERTER 3P 220VAC 1.5KWAB 22F-B8P0N103 | 1 |

| 7-E1292401 | SWITCH SNAP ACTION 15 A125/250 | 2 |

| 7-L302050 | ASSY PT100 FOR TUNNEL | 1 |

| 7-L600081 | HEATER SEALING RUBBER | 1 |

| 7-L600467 | COUPLING O2 SAMPLE | 3 |

| 7-18283 | HOSE CLAMP TJBC 40-60 | 8 |

| 7-42723 | HOSE CLAMP TJBC 25-40 | 4 |

| 7-47222 | GRID T-99 PROX-SVERS1/4″ | 0.26 |

| 7-L301867 | ASSY SPARE PT100 CATHOX | 1 |

| 7-L602473 | GRAPHITE COMPOSITE SEALING CATHOX BODY FLEX | 4 |

| 7-C99010 | SENSOR AUTONICS E40S-60-3-T+CONNECTOR | 1 |

| 7-C99136 | ENCODER SENSOR AUTONICSE40S6-500-3-T-24 5M CAB | 1 |

| 7-C00151 | GREASE KRYTOX GPL227(50ML) | 2 |

| 7-C00152 | HIGHT TEMPERATURE CHAINOIL ANDEROL XL220(1L) | 1 |

| 7-C00821 | FILTER NONWOVEN FABRIC 239*596*25 | 4 |

| 7-L301879 | ASSY HEAT EXCHANGERW/HTR QUICK | 1 |

| 7-L602701 | SEAL PLATE QUCIK DISCONNECT | 1 |

1.2 Key Energy-Efficient Components

- New Air Flow System: Extracts flux-contaminated air efficiently while reducing refresh time

- CATHOX System: Operates at 185-250°C, requiring minimal additional heating for maintenance

- Dual Lane Configuration: Maximizes throughput while maintaining optimal energy usage

- Heat Transfer Components: Delivers superior thermal performance with lower zone settings

The Vitronics Soltec Centurion reflow spare parts play a crucial role in maintaining energy efficiency through their innovative design. The system’s modular construction allows for strategic component placement that maximizes heat transfer while minimizing energy consumption.

When implementing Vitronics Soltec Centurion reflow spare parts, I recommend prioritizing the CATHOX components, as they significantly reduce maintenance requirements while operating at temperatures close to zone settings, minimizing additional energy needs. The new air flow system components should be regularly inspected and maintained to ensure optimal extraction of flux-contaminated air, maintaining system efficiency.

For maximum energy efficiency, focus on maintaining the heat transfer components, which are designed to deliver superior performance at lower zone settings. The dual lane configuration spare parts should be regularly calibrated to ensure balanced energy distribution across both lanes.

The integration of proper thermal management spare parts ensures consistent temperature profiles while minimizing energy waste. Regular replacement of these components maintains the system’s ability to operate at optimal efficiency levels.

Claims Verification:

✓ TRUE: Vitronics Soltec Centurion reflow spare parts with CATHOX technology operate at 185-250°C, significantly reducing energy consumption compared to traditional pyrolysis systems.

✗ FALSE: All Vitronics Soltec Centurion reflow spare parts require weekly maintenance – in reality, CATHOX components typically need servicing only once per year.

2. Conclusion

The Vitronics Soltec Centurion reflow system’s spare parts are essential for maintaining industry-leading performance and reliability. Critical components include the patented CATHOX residue management units that operate at 185-250°C, requiring minimal maintenance. The system’s modular construction allows for easy component replacement and upgrades. For optimal performance, focus on heat transfer components, conveyor systems, and zone-specific catalytic units. Regular maintenance of these parts ensures consistent temperature profiles, reduced energy consumption, and maximum uptime in 24/7 production environments.

3. Frequently Asked Questions

1. What documentation do I need when ordering spare parts?

You must provide your machine serial number and a clear description or picture of the part location in the machine for accurate identification1.

2. How does the CATHOX system impact maintenance?

The CATHOX (Catalytic Thermal Oxidizer) technology significantly reduces maintenance requirements through advanced flux treatment capabilities3.

3. What are the key thermal components?

The system features forced-convection components with closed-loop process control, designed for high-throughput PCB assembly environments2.

External links recommendation:

1.ITW EAE Support Portal

Access comprehensive spare parts documentation and technical support services. Remember to have your machine serial number ready when requesting specific parts5.

2. Vitronics Soltec Technical Hub

Find detailed component specifications and maintenance guidelines for the Centurion’s heating elements, CATHOX units, and conveyor systems6.

3. IPP Group Platform

Source authentic spare parts through authorized distributors, with access to the complete range of Centurion system components7.