As an expert in SMT equipment, I can confirm that having a comprehensive MPM Spare Parts Lists for the Momentum II Rail is essential for maintaining optimal performance and minimizing downtime. These lists ensure that all necessary components are readily available for both routine maintenance and emergency repairs.

Complete MPM Spare Parts Lists for Momentum II Rail include critical parts such as 2001460 and 2001466. Level 1 spares focus on wear items and lower-cost parts for annual preventative maintenance, while Level 2 spares cover more critical components that could lead to machine downtime if not promptly replaced.

To ensure seamless operations, I recommend establishing a proactive spare parts management strategy. This involves regularly reviewing your spare parts inventory, ensuring that both Level 1 and Level 2 parts are adequately stocked, and maintaining an updated list of part numbers and suppliers.

Claims:

- True: The Momentum II Rail spare parts list includes both Level 1 and Level 2 components to prevent machine downtime.

- False: All spare parts require specialized tools for replacement; in reality, many parts are designed for quick replacement using standard tools.

Table of Contents

- How Does the MPM Spare Parts List Support Preventive Maintenance for Momentum II Rail?

- What Critical Components Are Included in the MPM Spare Parts List for Momentum II Rail?

- Conclusion

- Frequently Asked Questions

1. How Does the MPM Spare Parts List Support Preventive Maintenance for Momentum II Rail?

As a maintenance specialist, I can confirm that the MPM Spare Parts Lists plays a crucial role in supporting preventive maintenance for the Mpm Printer Momentum II Rail by providing comprehensive coverage of both routine wear items and critical components.

1.1 Essential Maintenance Components

- Annual wear items for preventive maintenance

- Lower-cost critical spare parts

- Belt pulleys and clutch components

- Pneumatic system parts

- Clamp and sensors

1.2 Maintenance Strategy Recommendations

MPM Spare Parts Lists enables effective preventive maintenance by categorizing components into Level 1 spares for annual replacement and routine maintenance needs. This systematic approach helps maintenance teams plan and execute scheduled maintenance activities while minimizing the risk of unexpected downtime.

To maximize the effectiveness of the MPM Spare Parts Lists, I recommend implementing a structured inventory management system that tracks part usage patterns and maintains minimum stock levels. This proactive approach ensures critical components are always available when needed, particularly for high-wear items like Mpm Printer belts, bearing, pulleys, and motor that directly impact system performance.

Claims:

- True: Level 1 spares are specifically designated for annual preventative maintenance and include lower-cost critical parts1.

- False: MPM spare parts require specialized ordering procedures; in fact, they can be easily identified and ordered through standard technical support channels with machine serial numbers.

2. What Critical Components Are Included in the MPM Spare Parts List for Momentum II Rail?

As a maintenance specialist, I can confirm that the MPM Spare Parts Lists for Momentum II Rail includes critical components essential for preventing machine downtime and maintaining optimal performance in high-volume production environments.

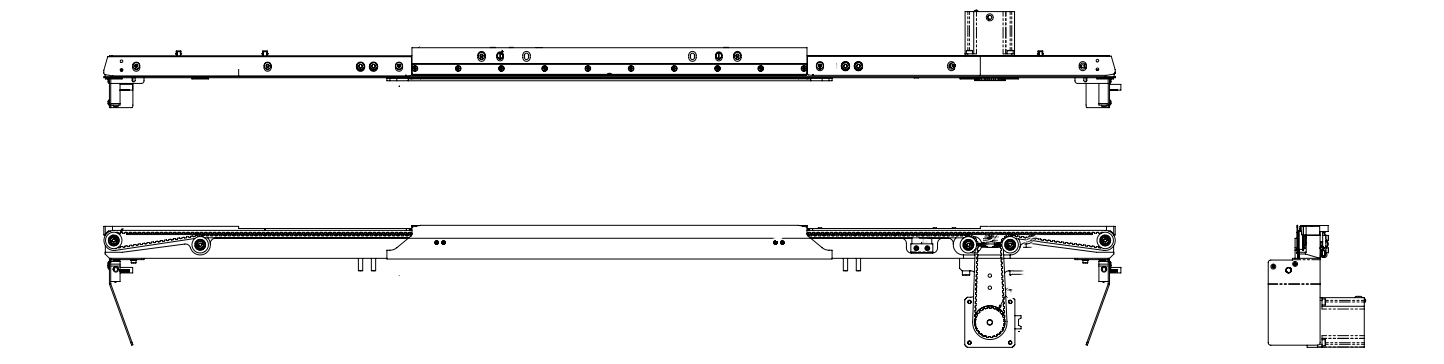

2.1 Mpm Printer 2001460 Fixed Rail Critical Components Overview

| PARTS LIST | ||||

| ITEM | PART NO . | DESCRIPTION | QTY | UM |

| 1 | 1009090 | SHAFT, IDLER PULLEY | 5 | EA |

| 2 | 1009116 | SPRING, TENSION, ASSY | 1 | EA |

| 3 | 1014390 | BRACKET, MOTOR MOUNT | 1 | EA |

| 4 | 1014949 | MOUNT, BOARD CLAMP | 2 | EA |

| 5 | 1014951 | BELT, TRANSPORT, SINGLE TRACK | 1 | EA |

| 6 | 1014959 | GUIDE,BOARD,LEFT FRONT,RIGHT REAR | 1 | EA |

| 7 | 1014960 | GUIDE,BOARD,RIGHT FRONT,LEFT REAR | 1 | EA |

| 8 | 1015775 | CLAMP, FOIL, 20 DEGREE | 1 | EA |

| 9 | 1015843 | PULLEY, TIMING, 5 .08XL PITCH, 22 GROOVE, 6.35 BORE | 1 | EA |

| 10 | 2005751-02 | MOTOR, ROTORY STEPPER,1 .26N .M,3 .9A,1 STACK,ASSY | 1 | EA |

| 11 | 2006031 | SUPPORT, BOARD | 1 | EA |

| 12 | 2001458 | GUARD,PINCH POINT,LOWER,FRONT LEFT | 1 | EA |

| 13 | 2001459 | GUARD,PINCH POINT,LOWER,FRONT RIGHT | 1 | EA |

| 14 | 2001463 | GUIDE PLATE,CENTER,RAIL CONVEYOR | 1 | EA |

| 15 | 2001467 | PULLEY,IDLER,ASSY | 5 | EA |

| 16 | 2001468 | RAIL, ASSY, WITH PIN | 1 | EA |

| 17 | 10032901 | CLAMP, WIRE/CABLE, 3 .2MM ID X 2 .9MM WD NYLON, CLR | 5 | EA |

| 18 | 10032921 | CLAMP, CABLE, 8.0MM ID X 6.4MM WD, BLACK | 1 | EA |

| 19 | A2-397 | BRUSH, ANTI-STATIC CONVEYOR BELT | 1 | EA |

| 20 | P61287 | TUBING, .093 ID X .156 OD | 1 | IN |

| 21 | *P60430/P7214 | BEARING, LINEAR WAY | 4 | EA |

| 22 | P7390 | FITTING,ELBOW,2 .5MM BARB,M3M,BRASS,SWIVE | 2 | EA |

| 23 | p9390 | CYLINDER,AIR,D-ACTING, 10 MM X 8MM | 2 | EA |

| 24 | P9698 | MOUNT, WIRE, TIE, #6 | 1 | EA |

| 25 | P10487 | SCREW, SHALLOW, SHOULDER, SLOTTED, 4MM X 2MM X M3 | 2 | EA |

| 26 | P10702 | FITTING,L-TEE,2MM TUBE ID, BARB | 1 | EA |

| 27 | P11084 | SCREW,CROSS RECESSED FLAT HEAD, M3- .5 X 5MM LG | 10 | EA |

2.2 Mpm Printer 2001466 Movable Rail Critical Components Overview

| PARTS LIST | ||||

| ITEM | PART NO . | DESCRIPTION | QTY | UM |

| 1 | 2001468 | RAIL, ASSY, WITH PIN | 1 | EA |

| 2 | 2001467 | PULLEY,IDLER,ASSY | 5 | EA |

| 3 | 1009090 | SHAFT, IDLER PULLEY | 5 | EA |

| 4 | 1014951 | BELT, TRANSPORT, SINGLE TRACK | 1 | EA |

| 5 | p9390 | CYLINDER,AIR,D-ACTING, 10 MM X 8MM | 2 | EA |

| 6 | P60430 | BEARING, LINEAR, 5 X 3.7 X 30MM, I CAR | 4 | EA |

| 7 | 1014949 | MOUNT, BOARD CLAMP | 2 | EA |

| 8 | 1014959 | GUIDE,BOARD,LEFT FRONT,RIGHT REAR | 1 | EA |

| 9 | 1014960 | GUIDE,BOARD,RIGHT FRONT,LEFT REAR | 1 | EA |

| 10 | 1015843 | PULLEY, TIMING, 5 .08XL PITCH, 22 GROOVE, 6.35 BORE | 1 | EA |

| 11 | 1014390 | BRACKET, MOTOR MOUNT | 1 | EA |

| 12 | A2-397 | BRUSH, ANTI-STATIC CONVEYOR BELT | 1 | EA |

| 13 | 2006031 | SUPPORT, BOARD | 1 | EA |

| 14 | P7390 | FITTING,ELBOW,2 .5MM BARB,M3M,BRASS,SWIVE | 2 | EA |

| 15 | 2001463 | GUIDE PLATE,CENTER,RAIL CONVEYOR | 1 | EA |

| 16 | P10702 | FITTING,L-TEE,2MM TUBE ID, BARB | 1 | EA |

| 17 | 1015775 | CLAMP, FOIL, 20 DEGREE | 1 | EA |

| 18 | P10487 | SCREW, SHALLOW, SHOULDER, SLOTTED, 4MM X 2MM X M3 | 2 | EA |

| 19 | 1009116 | SPRING, TENSION, ASSY | 1 | EA |

| 20 | P61287 | TUBING, .093 ID X .156 OD | 1 | IN |

| 21 | P11084 | SCREW,CROSS RECESSED FLAT HEAD, M3- .5 X 5MM LG | 10 | EA |

| 22 | HM1051F008 | SCREW,SOCKET SET,FLAT,M5 X 8,SS | 1 | EA |

| 23 | 10032901 | CLAMP, WIRE/CABLE, 3 .2MM ID X 2 .9MM WD NYLON, CLR | 5 | EA |

| 24 | P9698 | MOUNT, WIRE, TIE, #6 | 1 | EA |

| 25 | 2005751-01 | MOTOR, ROTORY STEPPER,1 .26N .M,3 .9A,1 STACK,ASSY | 1 | EA |

| 26 | 1009728 | GUARD,PINCH POINT,LOWER, REAR | 2 | EA |

| 27 | 10032921 | CLAMP, CABLE, 8.0MM ID X 6.4MM WD, BLACK | 1 | EA |

2.3 System Maintenance Strategy

MPM Spare Parts Lists includes essential components like 2001460 and 2001466, which are crucial for maintaining the printer’s core functionality. These parts are categorized as Level 2 spares, indicating their critical nature in preventing extended machine downtime situations.

To optimize maintenance operations, I recommend implementing a proactive spare parts management strategy. This should include maintaining an inventory of both Level 1 wear items for regular maintenance and Level 2 critical components. Regular monitoring of part conditions and establishing reorder points helps prevent unexpected downtime.

MPM Spare Parts Lists management system should be integrated with your preventive maintenance schedule. By tracking component lifecycles and maintaining detailed records of replacements, you can better predict when critical parts like motion control components and vision system elements need replacement, ensuring continuous production efficiency.

Claims:

- True: MPM Spare Parts Lists categorize components into Level 1 and Level 2, with Level 1 focusing on annual wear items and Level 2 covering critical components that could cause machine downtime.

- False: All spare parts require immediate replacement when received; in fact, they should be stocked based on wear patterns and critical nature of the components.

3. Conclusion

MPM Spare Parts Lists for Momentum II Rail represents a comprehensive solution for maintaining optimal printer performance. By strategically stocking both Level 1 wear items for annual maintenance and Level 2 critical components, manufacturers can effectively prevent unexpected downtime. The system’s plug-and-play architecture facilitates quick replacements, while the categorized spare parts ensure efficient maintenance scheduling. This proactive approach to spare parts management, combined with proper technical support and documentation, maximizes equipment reliability and production efficiency.

4. Frequently Asked Questions

1. What are the two main categories of MPM Momentum II Rail spare parts?

The spare parts are categorized into Level 1 (wear items for annual maintenance and low-cost critical parts) and Level 2 (comprehensive critical components that could cause machine downtime)16.

2. How do I identify the correct spare part for my machine?

Contact Technical Support with your machine serial number and provide a picture or description of the part’s location in the machine. This ensures accurate part identification6.

3. What types of components are included in the MPM spare parts list?

The list includes essential components like pulleys, belts, sensors, motors, cables, LED bulbs, filters, and emergency stop buttons. These parts are crucial for maintaining optimal printer performance1.

- ITW EAE Support Center – MPM Spare Parts

Access official Level 1 and Level 2 spare parts documentation, including wear items for annual maintenance and critical components for the Momentum II Rail system.

Source: ITW EAE Support - SMT Components – MPM Printer Parts Guide

Detailed catalog of Momentum II Rail components, including transport belts, pulleys, vision systems, and motion control parts with technical specifications.

Source: SMT Components - Speedline Technologies Parts Database

Comprehensive database featuring genuine MPM parts, including critical components like servo motors, control boards, and sensors for the Momentum II Rail.

Source: Speedline Technologies